Optical fiber ribbon residual torsion testing device and testing method thereof

A test device and residual torsion technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting the torsion angle of the optical fiber ribbon, large reading errors, and affecting test results, etc., to improve test accuracy and reduce readings Effect of error, exact determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

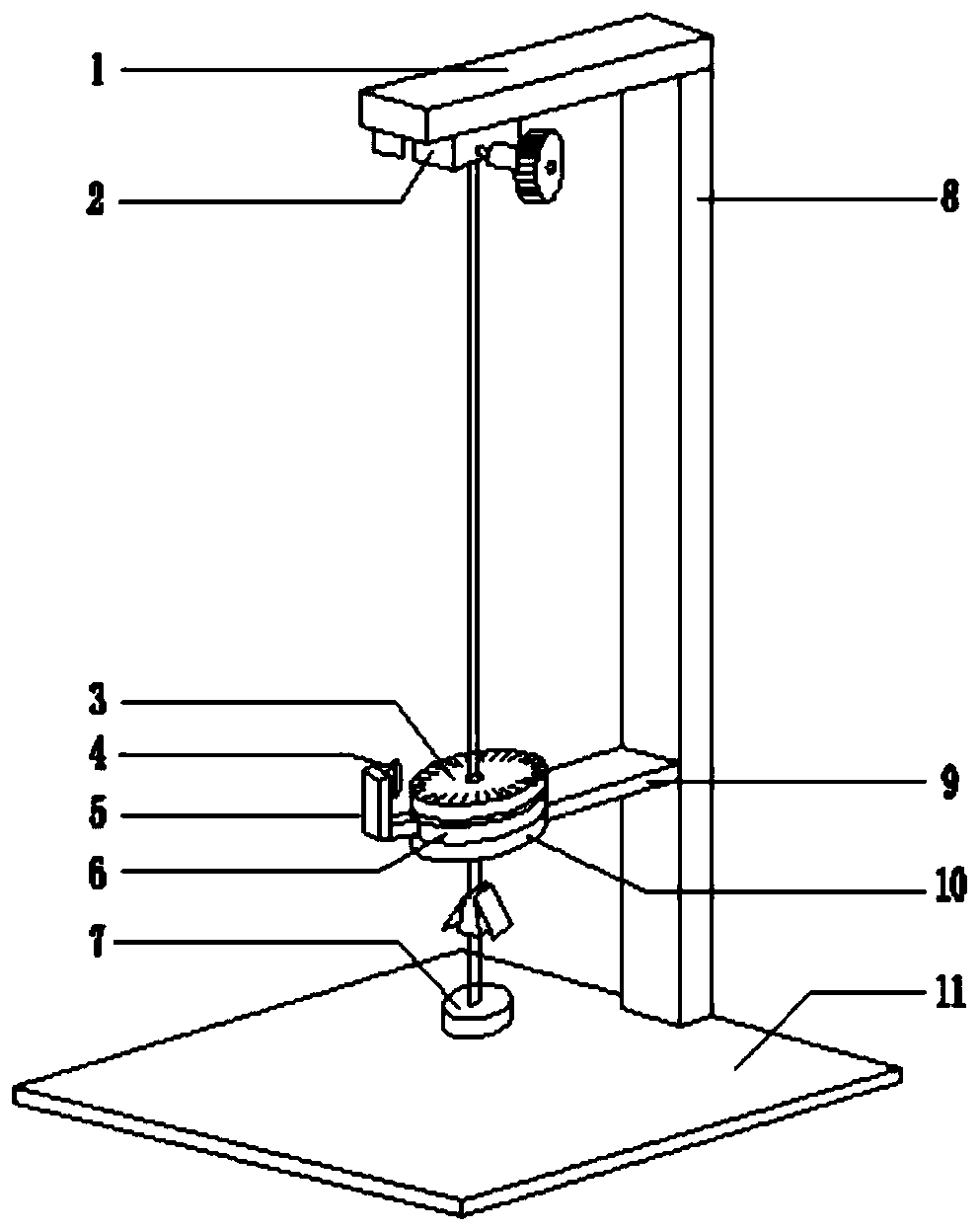

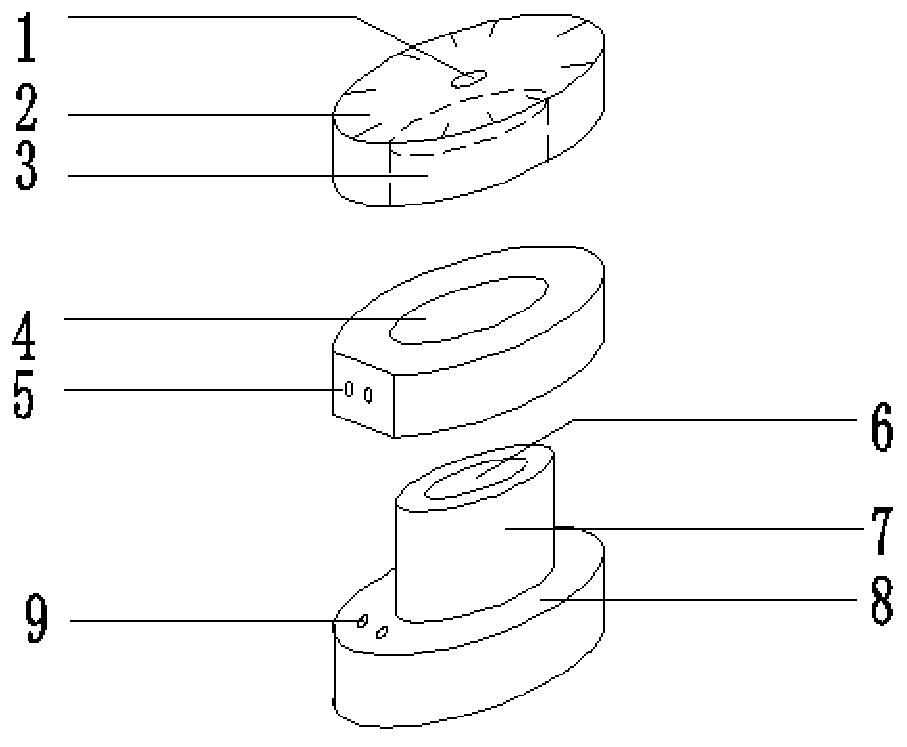

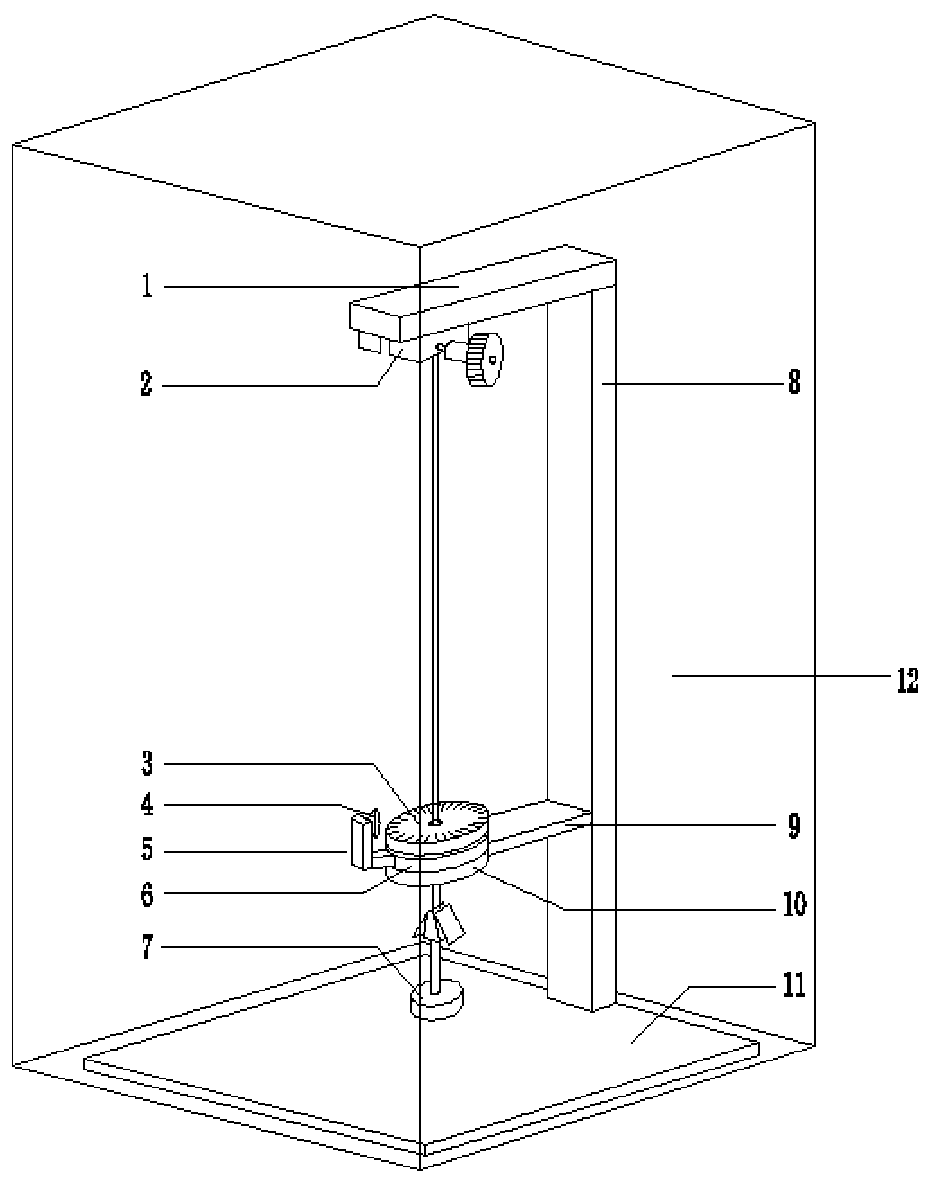

[0034] Such as figure 1 As shown, a fiber optic ribbon residual torsion test device includes: a support structure, a light source turntable 6, a dial 3, and a tray 10. The top of the support structure has an optical fiber ribbon fixing clip 2 for clamping the optical fiber ribbon to be tested. Between the top of the support structure and the base 11 of the support structure, a tray 10 fixed to the support structure on a horizontal plane is arranged; The disk 3 and the tray 10 have through holes in the same center, and the through holes are used to vertically pass through the optical fiber ribbon to be tested. The light source turntable 6 and the dial 3 can rotate horizontally independently of each other. The light source 4 is rotated by the light source turntable 6 , and the light source 4 irradiates the shadow of the optical fiber under test on the scale plate 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com