Liquidometer on-site detecting system and method for high-voltage direct-current converter valve cooling system

A high-voltage direct current and cooling system technology, applied in liquid/fluid solid measurement, measurement devices, test/calibration devices, etc., can solve the problems of high requirements for liquid level gauge transportation, large errors in manual readings, and affecting detection efficiency, etc. , to achieve the effect of improving test efficiency, reducing reading error and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

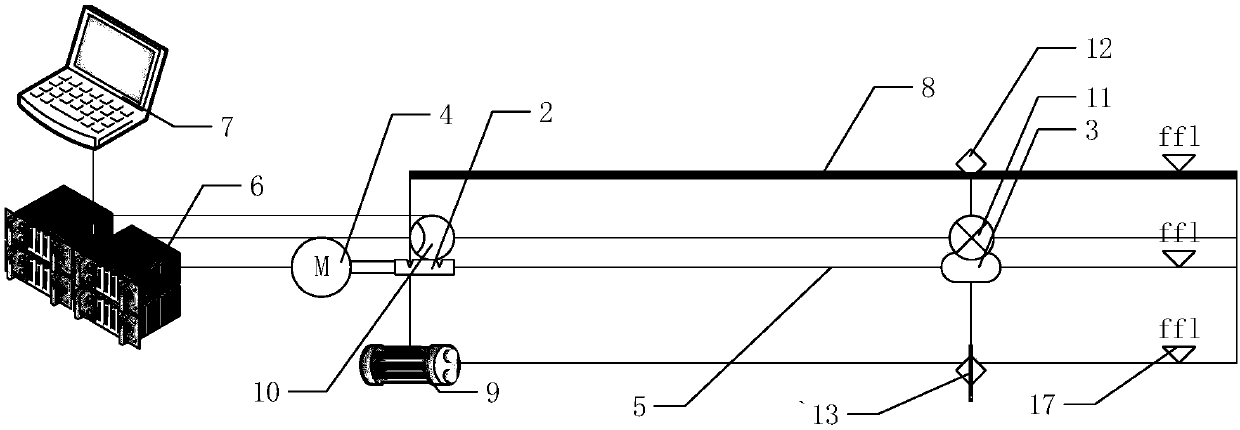

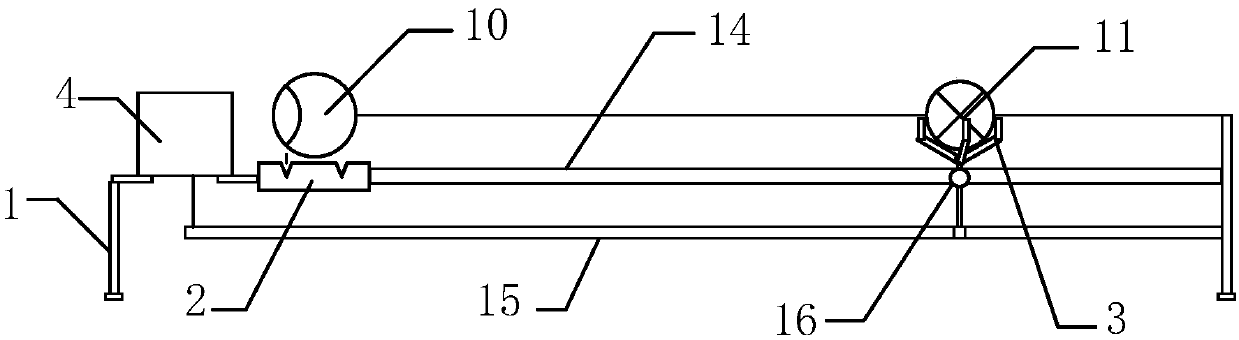

[0053] Such as figure 1 , figure 2 As shown, an on-site detection system for a liquid level gauge of a high-voltage DC converter valve cooling system includes a platform support 1, a transmitter base 2, a float base 3, a stepping motor 4, a linear displacement mechanism 5, and a control module 6. Computer module 7, steel ruler 8, laser rangefinder 9; the transmitter base 2 is used to clamp and fix the transmitter head 10 of the liquid level gauge, and the floating ball base 3 is used To clamp and fix the float 11 of the liquid level gauge, the transmitter base 2 and the float base 3 are respectively arranged on the linear displacement mechanism 5, and the stepping motor 4 drives the linear displacement mechanism 5 to make the float The base 3 moves back and forth linearly relative to the transmitter base 2. The measuring direction of the steel ruler 8, the ray direction of the laser rangefinder 9 and the moving direction of the linear displacement mechanism 5 are parallel to...

Embodiment 2

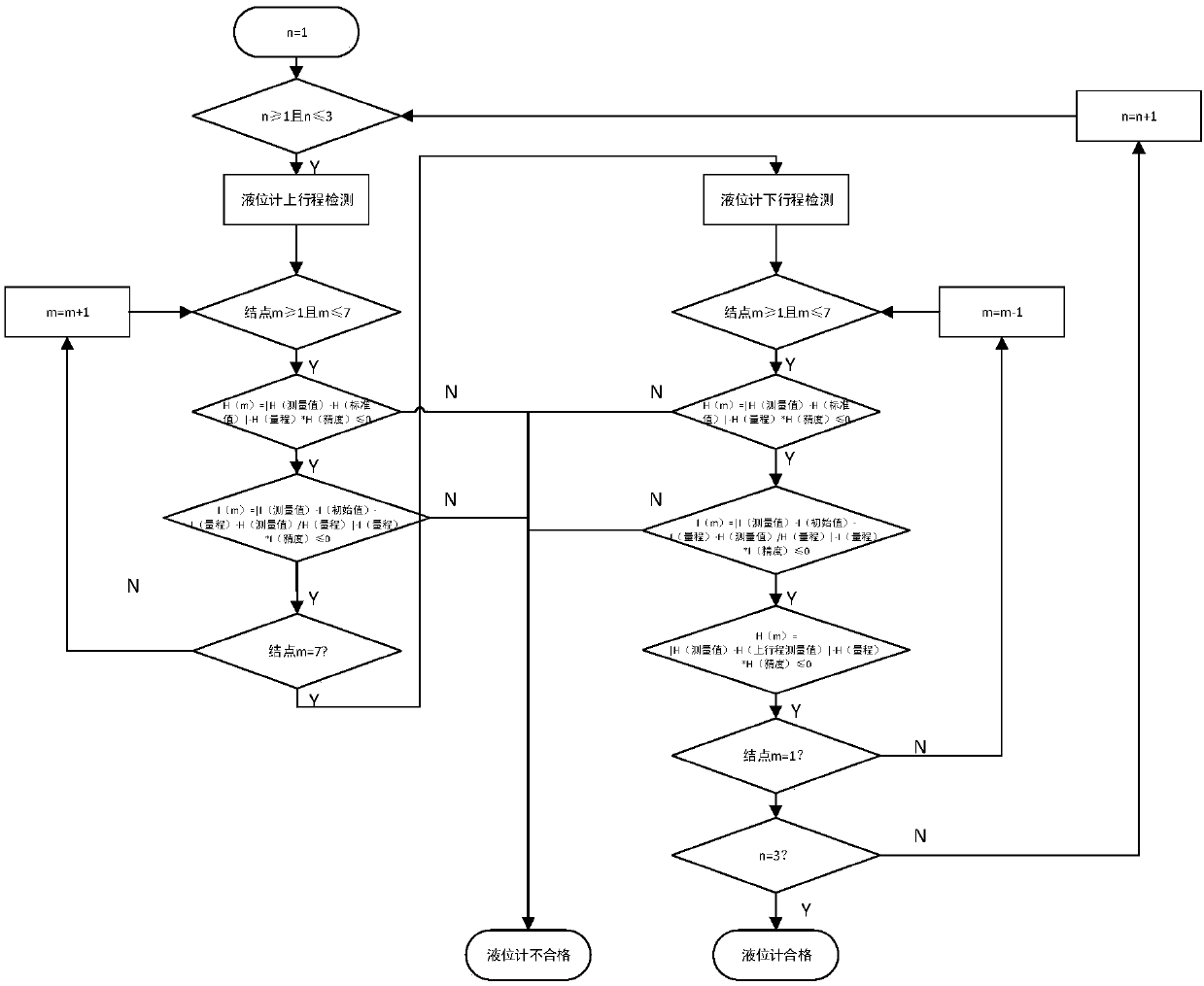

[0055] A method for on-site detection of a liquid level gauge in a cooling system of a HVDC converter valve, the specific steps are as follows:

[0056] Step 1. Install and fix the liquid level gauge, and adjust the level;

[0057] Step 2. If the liquid level meter is set point adjustable, proceed to step 10, if not, set the number of detection points, including the upper limit point, lower limit point and detection point, not less than 5 points;

[0058] Step 3. The equipment is initialized, the equipment drives the liquid level gauge to determine the full scale and zero position, and moves to the positions of each detection point at the same time;

[0059] Step 4. Preheat the liquid level gauge with power supply;

[0060] Step 5. Measure the indication value of each detection point. When detecting, use the method of "aligning with the standard to be inspected". The liquid level gauge under inspection starts from the zero position and gradually moves up to each detection poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com