Injection molding manipulator

A technology of manipulators and encoders, which is applied in the connection/disconnection of connection devices, electrical components, circuits, etc., can solve the problems of long wiring distance, many corners, and large corner angles, so as to improve product quality and reliability, reduce The difficulty of line inspection and the effect of reducing the unqualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present invention, and to fully convey the scope of the present invention to those skilled in the art.

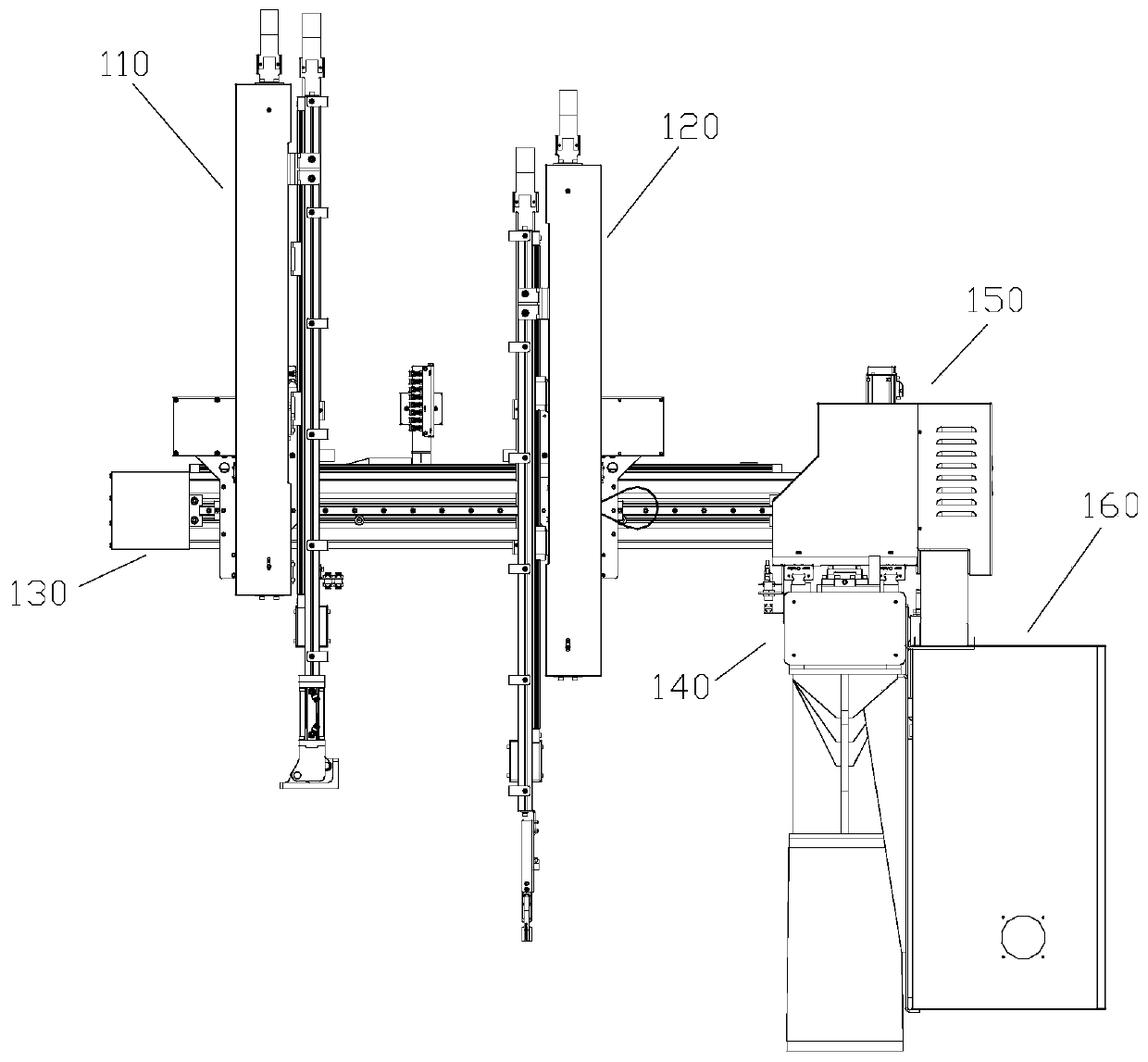

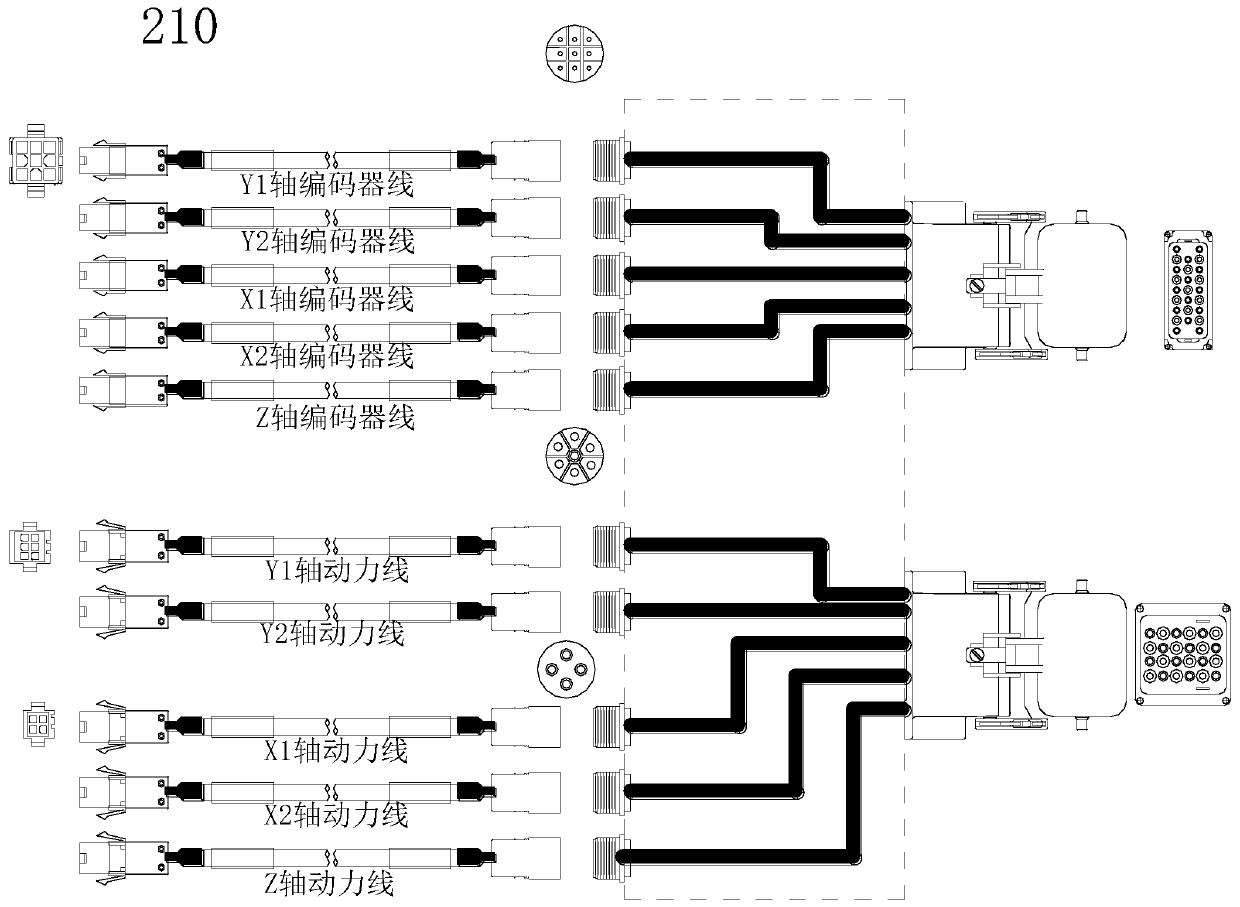

[0029] figure 1 It is a schematic structural diagram of an injection molding manipulator provided by an embodiment of the present invention. Such as figure 1 As shown, the body of the five-axis injection molding manipulator includes the main arm axis 110 (Y1 axis), the auxiliary arm axis 120 (Y2 axis), the drawing axis 130 (X1 axis and X2 axis), and the transverse axis 140 (Z axis), and also includes Junction box 150 and control cabinet 160....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com