Catalyst for eliminating volatile organic compounds and preparation method thereof

A technology for volatile organic compounds and catalysts, which is applied in the field of catalysts for eliminating volatile organic compounds and their preparation, can solve problems such as expensive catalysts, and achieve the effects of high catalytic performance, high reactivity and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1)Nb 2 o 5 -Al 2 o 3 -CeVO 4 Preparation of vector

[0017] According to Nb 2 o 5 / Al 2 o 3 Mass ratio = 1:1, Nb 2 o 5 -Al 2 o 3 The loading is CeVO 4 2wt%, weighed 0.11g niobium hydroxide (H 5 Nb 3 o 10 ) and 0.74g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) Add 10mL of water and mix, then add 10g CeVO 4 , and then dried at 120°C, and finally fired at 500°C in an air atmosphere for 4 hours to obtain Nb 2 o 5 -Al 2 o 3 -CeVO 4 carrier.

[0018] (2)Pt-MoO 3 / Nb 2 o 5 -Al 2 o 3 -CeVO 4 Catalyst preparation

[0019] Nb according to Pt loading 2 o 5 -Al 2 o 3 -CeVO 4 0.3 wt% of support, Pt / MoO 3 The mass ratio is 1:2, weigh 0.060g of platinum (II) acetylacetonate (0.030g of metal platinum) and 0.136g of molybdenum acetylacetonate (MoO 3 0.060g), was added to 20mL of dimethylformamide (DMF) solvent. Then add the above 10g Nb 2 o 5 -Al 2 o 3 -CeVO 4 Carrier, heated to 80°C under stirring condition, the DMF solvent was volatil...

Embodiment 2

[0023] (1)Nb 2 o 5 -Al 2 o 3 -CeVO 4 Preparation of vector

[0024] According to Nb 2 o 5 / Al 2 o 3 Mass ratio = 1:1, Nb 2 o 5 -Al 2 o 3 The loading is CeVO 4 4wt%, weighed 0.22g niobium hydroxide (H 5 Nb 3 o 10 ) and 1.48g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) Add 10mL of water and mix, then add 10g CeVO 4 , and then dried at 120°C, and finally fired at 500°C in an air atmosphere for 4 hours to obtain Nb 2 o 5 -Al 2 o 3 -CeVO 4 carrier.

[0025] (2)Pt-MoO 3 / Nb 2 o 5 -Al 2 o 3 -CeVO 4 The preparation of the catalyst was the same as in Example 1.

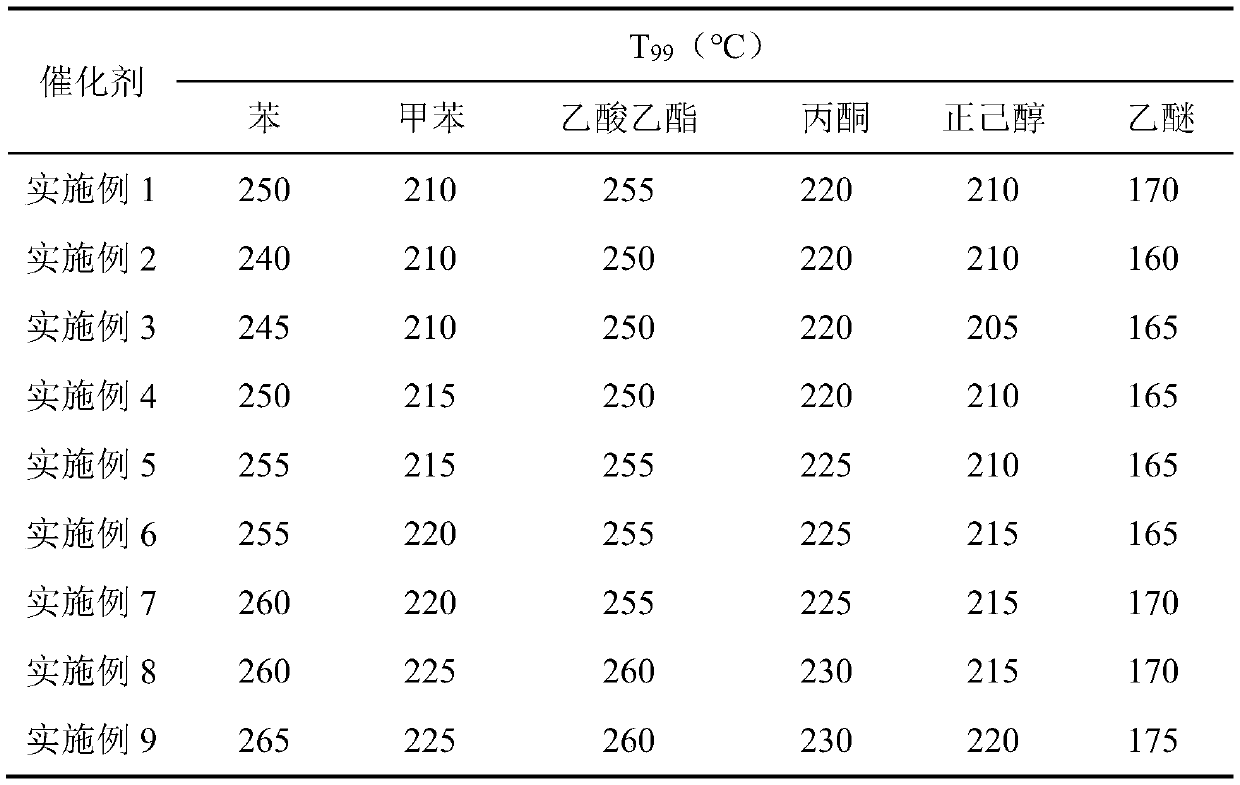

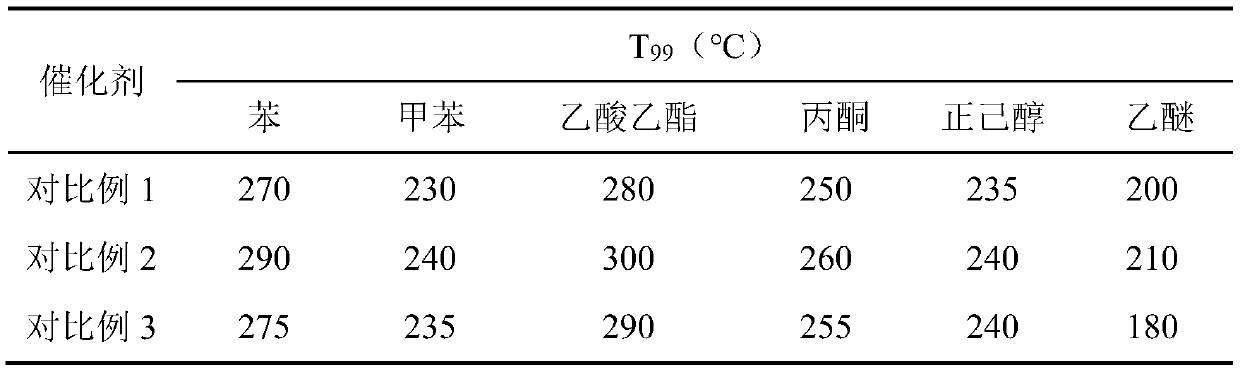

[0026] (3) Catalyst performance test is the same as in Example 1, and the catalytic reaction performance is shown in Table 1.

Embodiment 3

[0028] (1)Nb 2 o 5 -Al 2 o 3 -CeVO 4 Preparation of vector

[0029] According to Nb 2 o 5 / Al 2 o 3 Mass ratio = 1:1, Nb 2 o 5 -Al 2 o 3 The loading is CeVO 4 6wt%, weighed 0.33g niobium hydroxide (H 5 Nb 3 o 10 ) and 2.22g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) Add 10mL of water and mix, then add 10g CeVO 4 , and then dried at 120°C, and finally fired at 500°C in an air atmosphere for 4 hours to obtain Nb 2 o 5 -Al 2 o 3 -CeVO 4 carrier.

[0030] (2)Pt-MoO 3 / Nb 2 o 5 -Al 2 o 3 -CeVO 4 The preparation of the catalyst was the same as in Example 1.

[0031] (3) Catalyst performance test is the same as in Example 1, and the catalytic reaction performance is shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap