Method for preparing o-phenylphenol through dibenzofuran reduction

A technology of o-phenylphenol and oxyfluorene, which is applied in the field of preparation of o-phenylphenol by reduction of oxyfluorene, can solve the problems of low catalyst service life, high investment, and poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

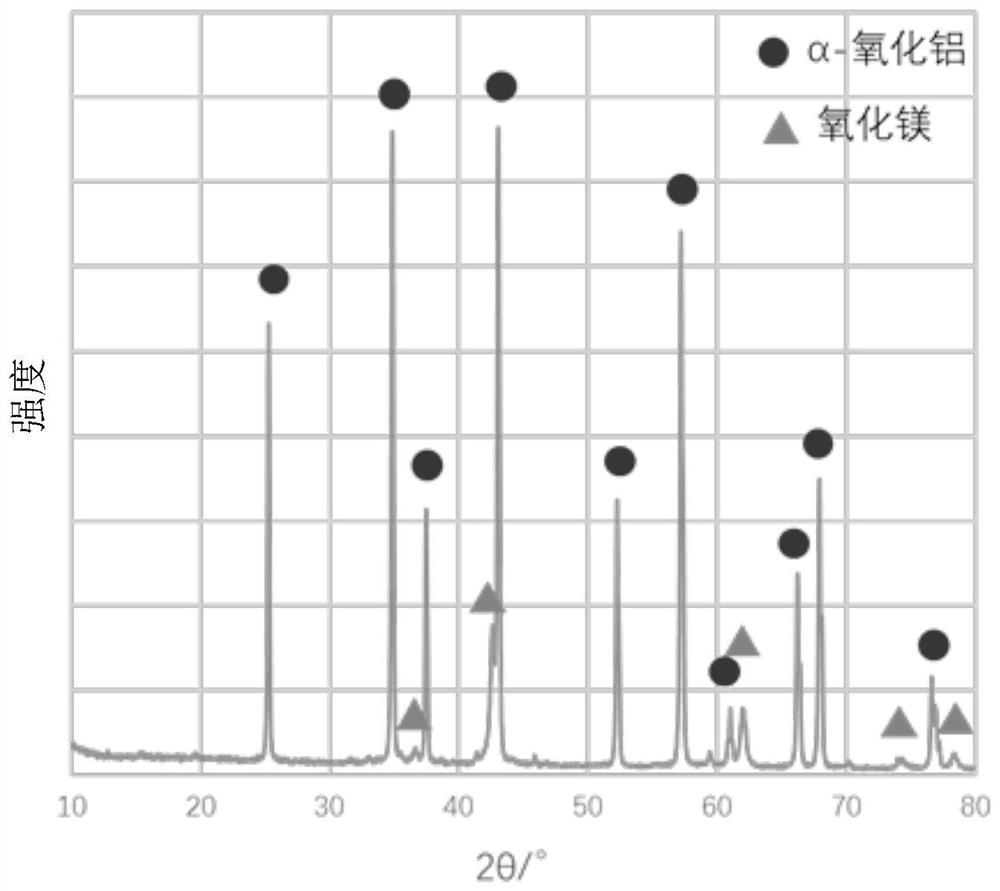

[0048] The method for preparing o-phenylphenol of the present invention comprises hydrogenating oxyfluorene in the presence of a catalyst, the catalyst comprises a carrier and an active component, and the carrier comprises α-Al 2 O 3 and MgO, the active components include one or more of platinum, palladium and rhodium.

[0049] In the present invention, the carrier has the conventional meaning in the art, and is the support of the active components in the catalyst. The present invention uses alumina of specific crystal form—α-Al 2 O 3 for the carrier core, in α-Al 2 O 3 The surface is coated with alkaline oxide to form an alkaline composite carrier with low specific surface area, and then the active metal is supported on this composite carrier. The utilization efficiency of the catalyst reduces the loading of precious metal components, is also conducive to the diffusion of reaction products, improves the OPP selectivity, and reduces the catalyst cost. The catalyst used i...

preparation example 1

[0081] Preparation Example 1: Catalyst Preparation

[0082] Take 100g of strip α-Al with a diameter of 3mm 2 O 3 Put it into the sugar-coating machine, the speed of the sugar-coating machine is 30r / min, and slowly spray 110g of magnesium nitrate aqueous solution with a magnesium nitrate mass fraction of 32% onto the surface of the carrier. During the whole spraying process, the sugar-coating machine is blasted and kept at 50 ℃ air temperature , after the spraying of the magnesium nitrate solution is completed, take out the carrier, dry it at 100 °C for 5 h, put the dried sample into the muffle furnace for calcination, and raise the temperature from room temperature to 600 °C at a heating rate of 5 °C / min, and then put it in a muffle furnace. Roast at 600°C for 5 hours, take out the carrier, put the carrier into the sugar coating machine, the sugar coating machine rotates at 30r / min, and spray 110g of magnesium nitrate aqueous solution with a mass fraction of 32% on the carrie...

Embodiment 1-5

[0085] Activation of the catalyst: 100 g of the catalyst prepared in Preparation Example 1 was filled into the fixed bed, and hydrogen was introduced into it. The hydrogen flow rate was 8 L / min, and the set pressure was 1.2 MPa, and the catalyst was raised to 400 ° C at a heating rate of 5 ° C / min. , at 400 °C for 4 hours to activate the catalyst.

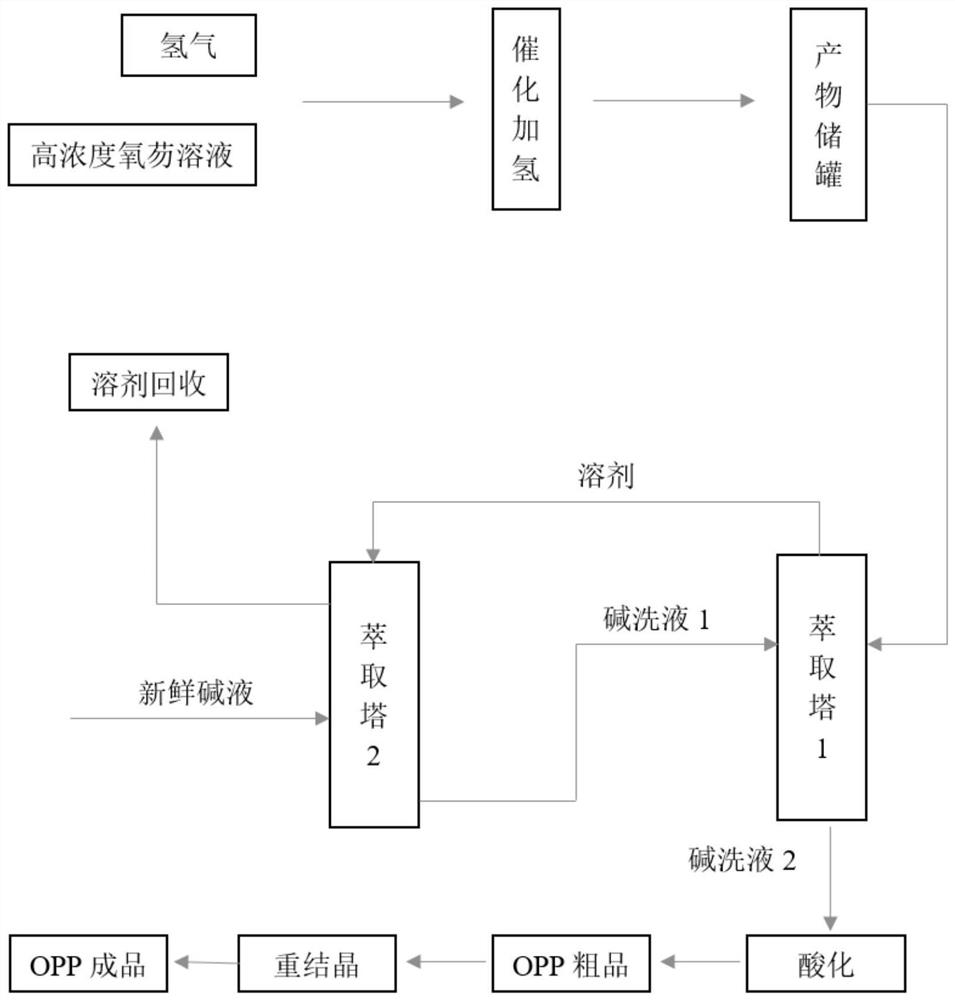

[0086] Reaction process: as figure 2 As shown in the schematic flow chart of , the oxyfluorene toluene solution (Example 1-4) or pure oxyfluorene (Example 5) with different oxyfluorene concentrations (20%-80%) is pumped into the preheater for gasification by the liquid feed pump, It is mixed with hydrogen, and after heating, it enters the fixed-bed reactor for catalytic reaction. The reaction conditions are: the mass space velocity of oxyfluorene (the mass flow rate of oxyfluorene / catalyst mass) is 0.8h -1 , the hydrogen flow rate satisfies that the ratio of hydrogen mass to oxygen fluorene mass is 0.4, the fixed bed catalytic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com