Catalyst and its preparation method

A technology of catalysts and additives, which is applied in the field of catalysts for eliminating volatile organic compounds and its preparation, can solve the problems of SOx secondary pollution, high price, and unfriendly environment, and achieve high catalytic performance, high reactivity, and low content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

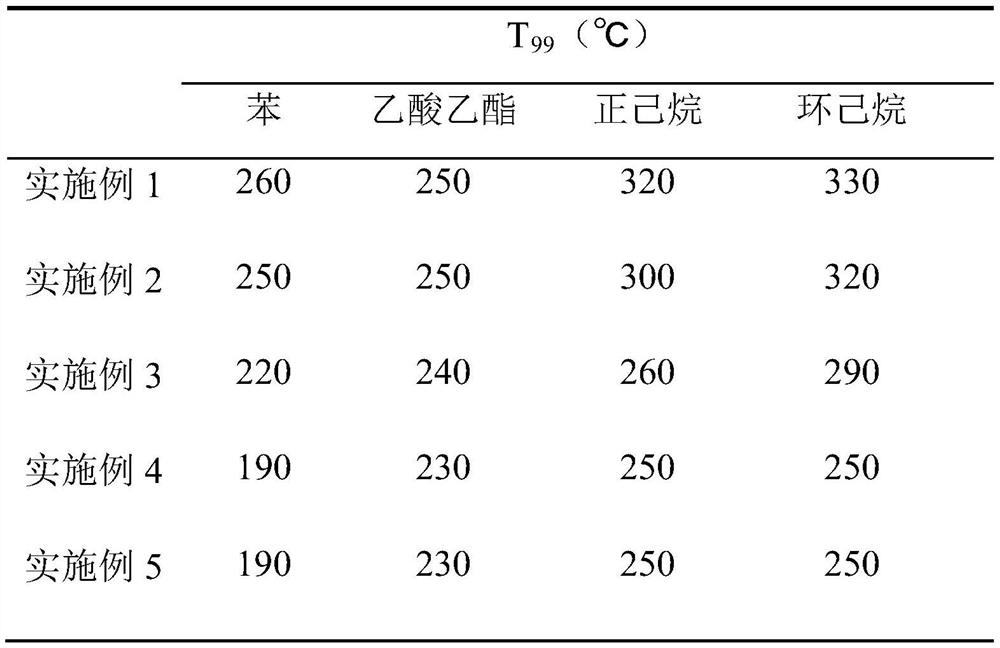

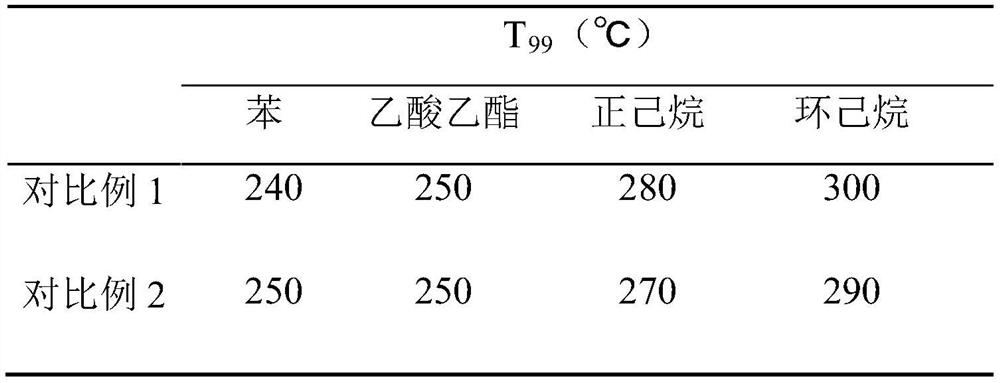

Examples

Embodiment 1

[0018] (1)V 2 o 5 - Preparation of HY-ZSM-5 vector

[0019] Follow V 2 o 5 , HY and ZSM-5 quality are V 2 o 5 This is calculated as 1 g of vanadyl oxalate, 4 g of HY molecular sieve and 10 g of ZSM-5 molecular sieve. Weigh vanadyl oxalate (VOC 2 o 4 ·5H 2 O) 2.69g was dissolved in 30ml of water, then 4g of HY molecular sieve and 10g of ZSM-5 molecular sieve were added, after mixing evenly, moisture was removed in a rotary evaporator at 100°C, and then roasted at 500°C in a muffle furnace for 4 hours to obtain V 2 o 5 - HY-ZSM-5 mixture.

[0020] (2)V 2 o 5 -N-butylamine treatment on the surface of HY-ZSM-5 carrier

[0021] Weigh 1g of n-butylamine and add it to 100ml of water, then add 14g of the above V 2 o 5 - The HY-ZSM-5 mixture was soaked for 1 hour, then the liquid was filtered off and dried in an oven at 80°C for 4 hours. V obtained by n-butylamine treatment 2 o 5 - HY-ZSM-5 vector.

[0022] (3) Pt / V 2 o 5 -Preparation of HY-ZSM-5 catalyst

[0023]...

Embodiment 2

[0027] (1)V 2 o 5 - The preparation of the HY-ZSM-5 carrier is the same as in Example 1.

[0028] (2)V 2 o 5 - The n-butylamine treatment on the surface of the HY-ZSM-5 carrier is the same as in Example 1.

[0029] (3) Pt / V 2 o 5 -Preparation of HY-ZSM-5 catalyst

[0030] n-Butylamine-treated V according to Pt loading 2 o 5 -0.3wt% of HY-ZSM-5 carrier, weigh 1g of platinum nitrate aqueous solution containing 0.03g of metal Pt, add water and dilute to 20ml, then add n-butylamine-treated V 2 o 5 - HY-ZSM-5 carrier 10g, remove moisture in a rotary evaporator at 100°C, then put it into a tube furnace, feed in an oxygen-nitrogen mixture containing 2% oxygen, and raise the temperature to 10°C / min. 500°C, after holding for 4 hours, switch the air and continue roasting for 4 hours, then reduce the temperature to 250°C and introduce 5000mg / m 3 The air of butyl acetate activated the catalyst for 12 hours to obtain 0.3Pt / V 2 o 5 - HY-ZSM-5 catalyst.

[0031] (4) Catalyst pe...

Embodiment 3

[0033] (1)V 2 o 5 - The preparation of the HY-ZSM-5 carrier is the same as in Example 1.

[0034] (2)V 2 o 5 - The n-butylamine treatment on the surface of the HY-ZSM-5 carrier is the same as in Example 1.

[0035] (3) Pt / V 2 o 5 -Preparation of HY-ZSM-5 catalyst

[0036] n-Butylamine-treated V according to Pt loading 2 o 5 -0.5wt% of HY-ZSM-5 carrier, weigh 1g of platinum nitrate aqueous solution containing 0.05g metal Pt, add water and dilute to 20ml, then add n-butylamine-treated V 2 o 5 - HY-ZSM-5 carrier 10g, remove moisture in a rotary evaporator at 100°C, then put it into a tube furnace, feed in an oxygen-nitrogen mixture containing 2% oxygen, and raise the temperature to 10°C / min. 500°C, after holding for 4 hours, switch the air and continue roasting for 4 hours, then reduce the temperature to 250°C and introduce 5000mg / m 3 The air of butyl acetate activated the catalyst for 12 hours to obtain 0.5Pt / V 2 o 5 - HY-ZSM-5 catalyst.

[0037] (4) Catalyst perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com