Machine part production paint spraying device

A technology of mechanical parts and the other side, applied in the field of paint spraying device production of mechanical parts, can solve the problem of inability to dry the board, and achieve the effect of improving stability, improving uniformity and adequacy, and ensuring completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

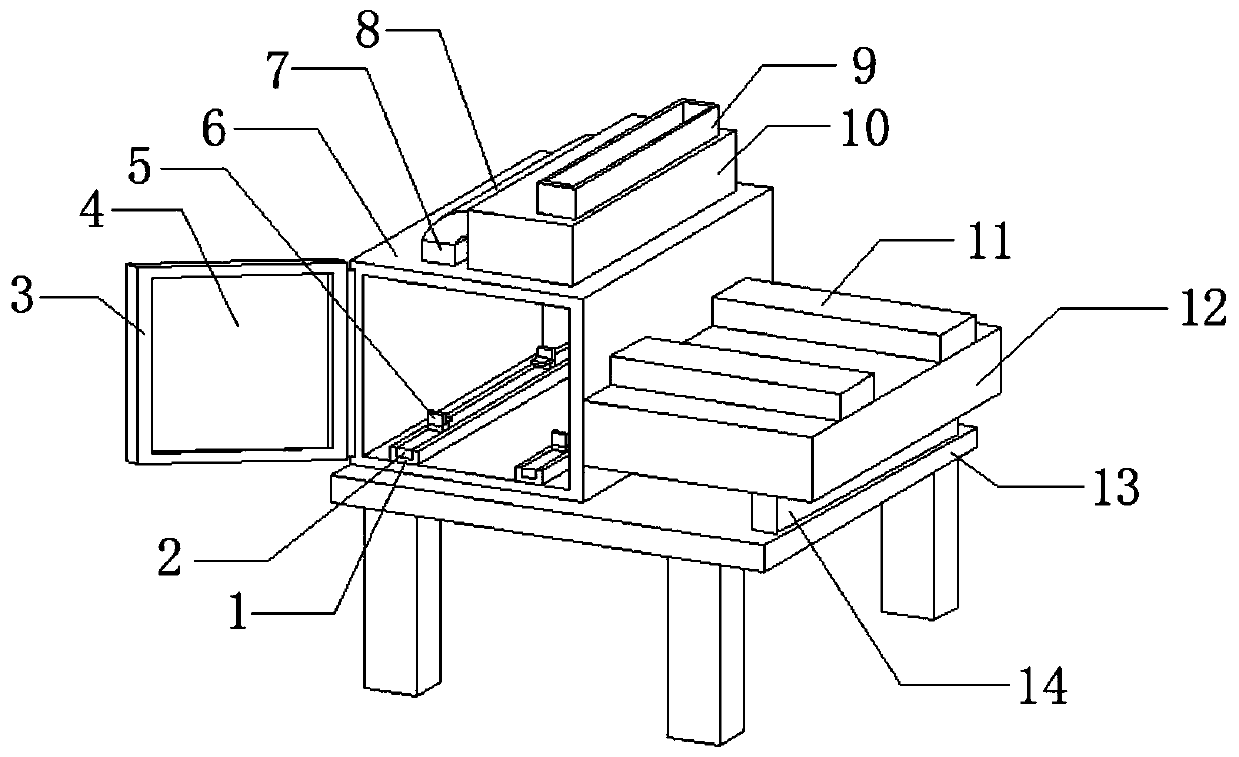

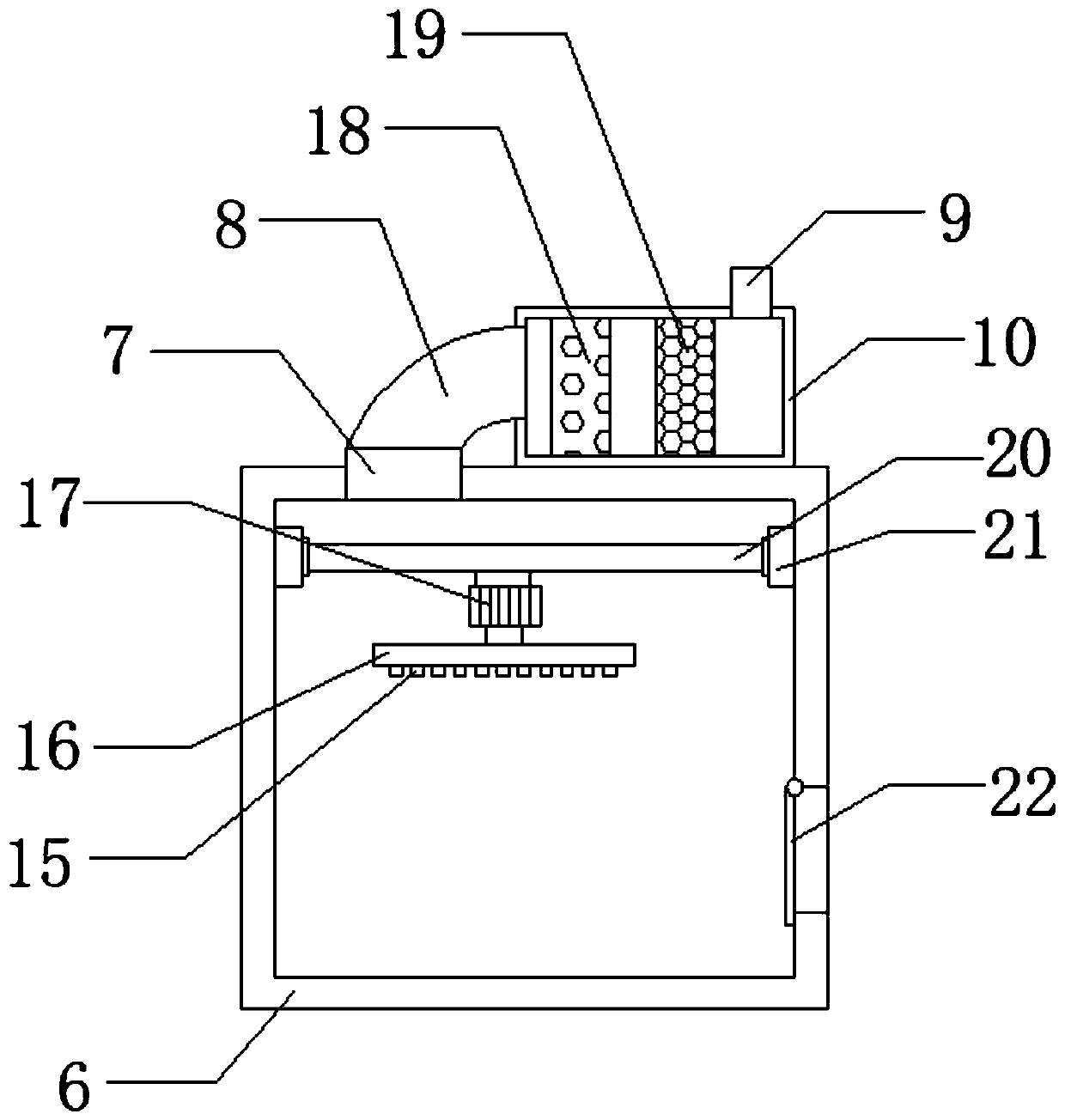

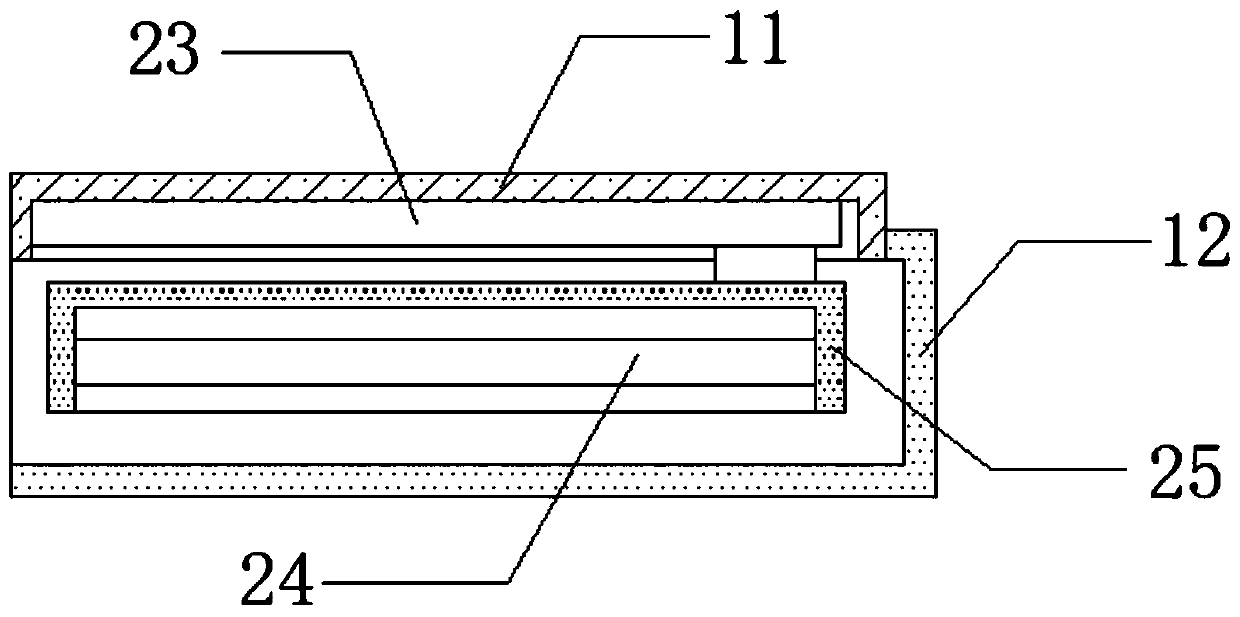

[0029] refer to Figure 1-3 , a painting device for the production of mechanical parts, comprising a support base 13 and four support legs, the four support legs are respectively installed on the bottom four-corner outer walls of the support base 13 by bolts, and the top side outer wall of the support base 13 is connected with a paint spraying box by bolts body 6, and the bottom outer wall on one side of the paint spraying box body 6 is connected with a third supporting shell 12 arranged horizontally by bolts, and the outer walls at both ends of the top of the third supporting shell 12 are connected with a second supporting shell 11 by bolts. The top inner wall of each second supporting shell 11 is connected with the third electric guide rail 23 by bolts, the bottom outer walls of the two third electric guide rails 23 are all slidably connected with the third electric slider, the bottom of the two third electric slider The same fourth support shell 25 is connected by bolts, th...

Embodiment 2

[0034] refer to Figure 1-4 , a paint spraying device for producing mechanical parts, also includes a support screen 26 installed at the same level on the bottom inner wall of the paint spray box body 6 both sides by bolts, and two support groove plates 1 are installed on the support screen 26 by bolts The same slag storage tank plate 27 is plugged between the outer walls on both sides of the top, the inner wall at the bottom of the painting box body 6 and the outer wall at the bottom of the support net plate 26 .

[0035] In the process of use, the paint slag produced by the painting process is collected by the slag storage tank plate 27. After the painting is completed, the slag storage tank plate 27 is pulled out to facilitate the unified cleaning of the paint slag and avoid long-term accumulation of paint slag in the spray paint. The bottom of the box affects the use of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com