Instrument washing device for drug and equipment section

A technology for flushing devices and instruments, which is applied to chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc. It can solve the problems of poor instrument flushing effect, inability to reduce the workload of medical staff, and low efficiency, and achieve an improvement. Action effect, enhanced removal effect, enhanced rinse effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

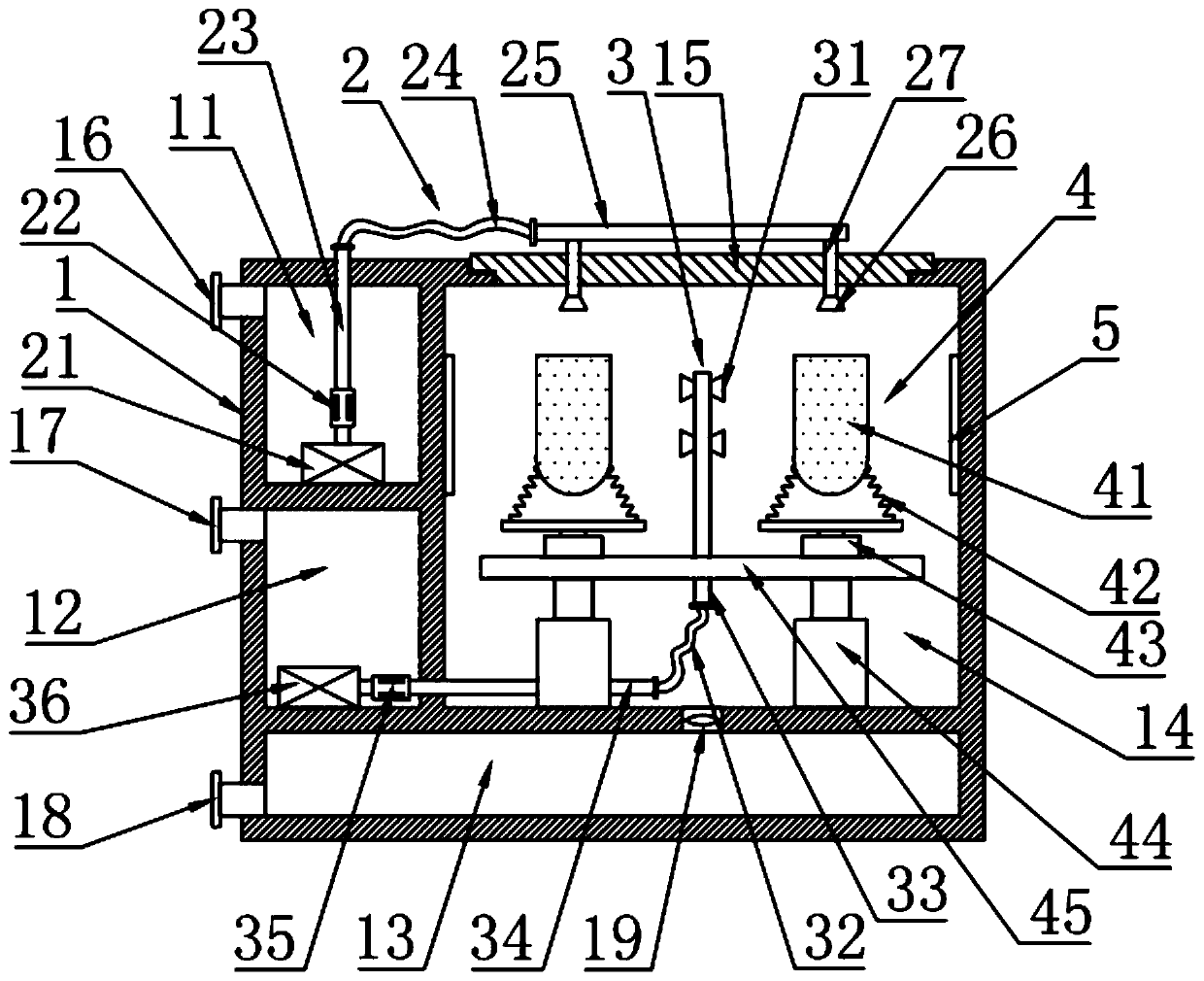

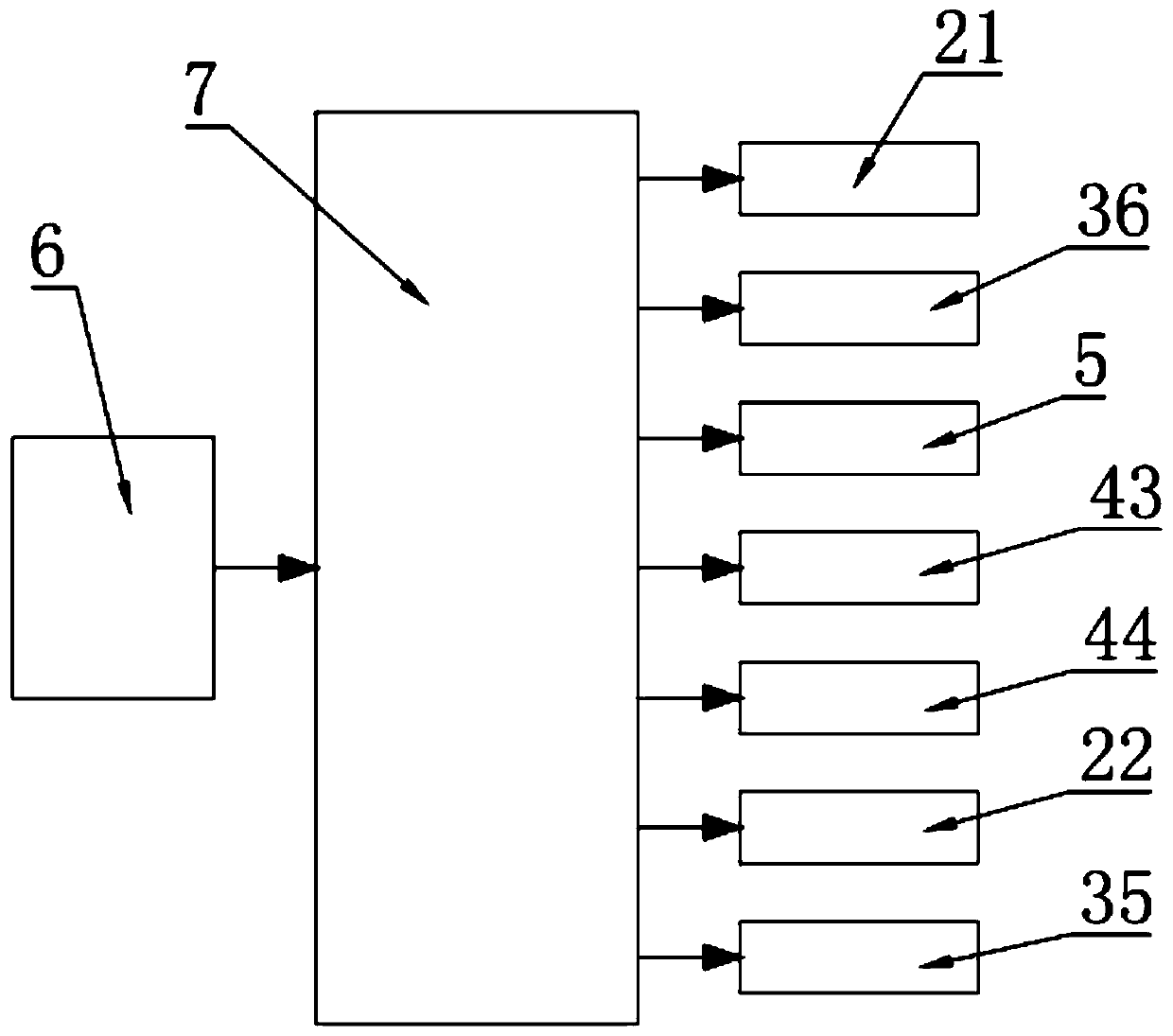

[0033] see figure 1 , in an embodiment of the present invention, a medical instrument flushing device includes a body 1, the upper and lower parts on the left side of the body 1 are respectively provided with a closed first flushing liquid chamber 11 and a second flushing liquid chamber 12, the body 1 is provided with an instrument flushing chamber 14 with an upper opening, the top of the instrument flushing chamber 14 is provided with a sealing cover 15, and the second flushing liquid chamber 12 and the lower side of the instrument flushing chamber 14 are provided with a closed waste liquid chamber 13, and the waste liquid chamber 13 and the instrument flushing chamber 14 are communicated through a communication port 19, and a one-way valve (not shown) is also arranged on the communication port 19, and the flushing liquid in the instrument flushing chamber 14 can pass through the communication port 19 flows into the waste liquid chamber 13 for storage, and the one-way valve p...

Embodiment 2

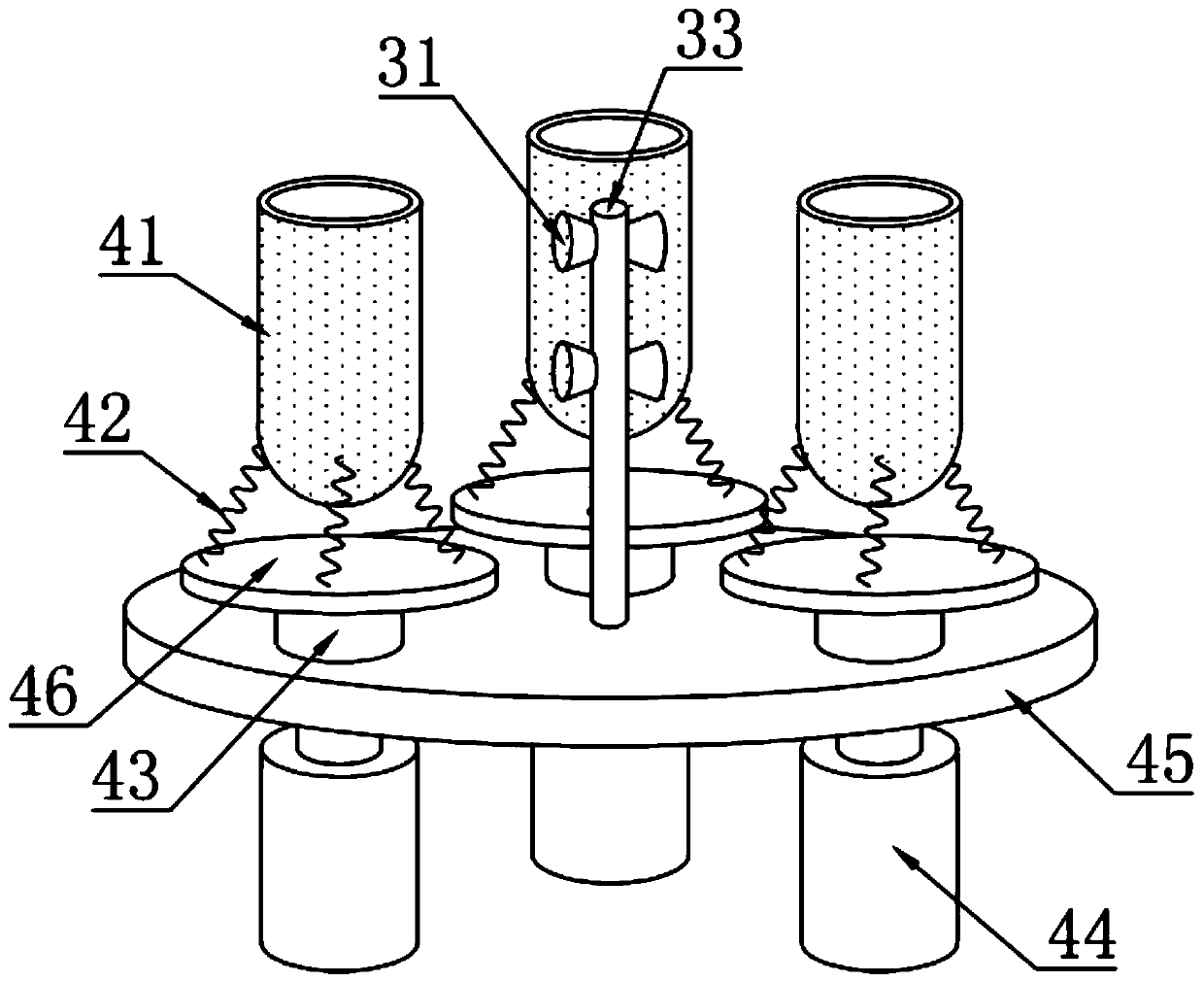

[0037] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

[0038] In this embodiment, the instrument carrying device 4 includes an instrument placement box 41, a support spring 42, a rotating motor 43, a telescopic cylinder 44, a mounting plate 45 and a carrying plate 46, the mounting plate 45 is a disc-shaped structure, and the mounting plate The lower side of 45 is circumferentially provided with a plurality of telescopic cylinders 44, and the lower end of the telescopic cylinders 44 is fixed on the bottom of the instrument flushing chamber 14, and the telescopic cylinders 44 are used to stably support the mounting plate 45 and drive the mounting plate 45 to move up and down. Above the mounting plate 45, a plurality of bearing plates 46 are arranged in the circumferential direction. The bearing plate 46 is a disc-shaped structure. A rotating motor 43 is fixedly arranged on the mounting plate 45 on the lower side of the bearing plate 46. The output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com