Optimized production method of high-efficiency low-noise axial flow fan

A technology of axial flow fan and production method, which is applied in the direction of casting molding equipment, casting molds, cores, etc., can solve the problems of difficult design, demanding noise requirements, and high research and development costs, so as to reduce energy consumption, improve production efficiency, The effect of increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

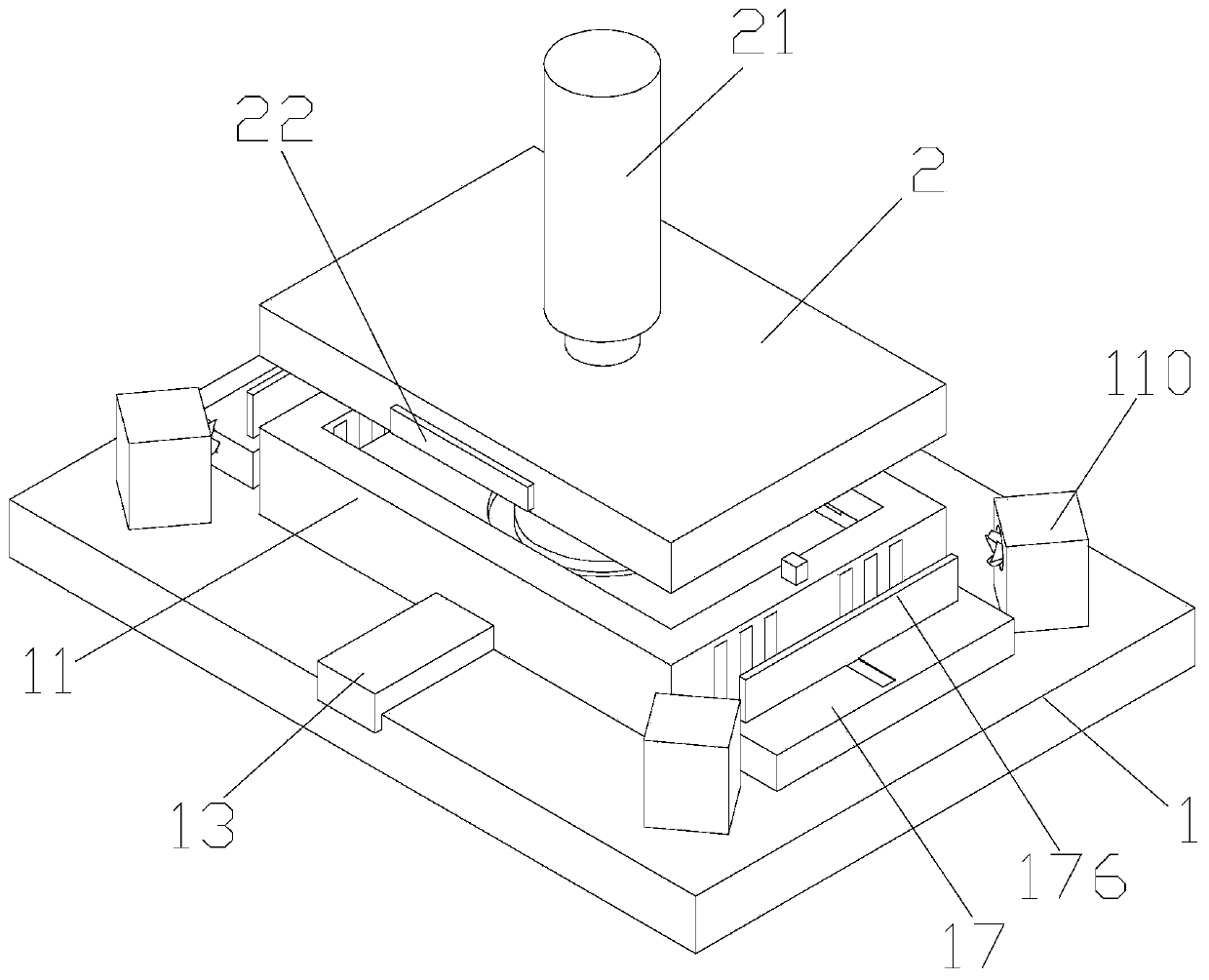

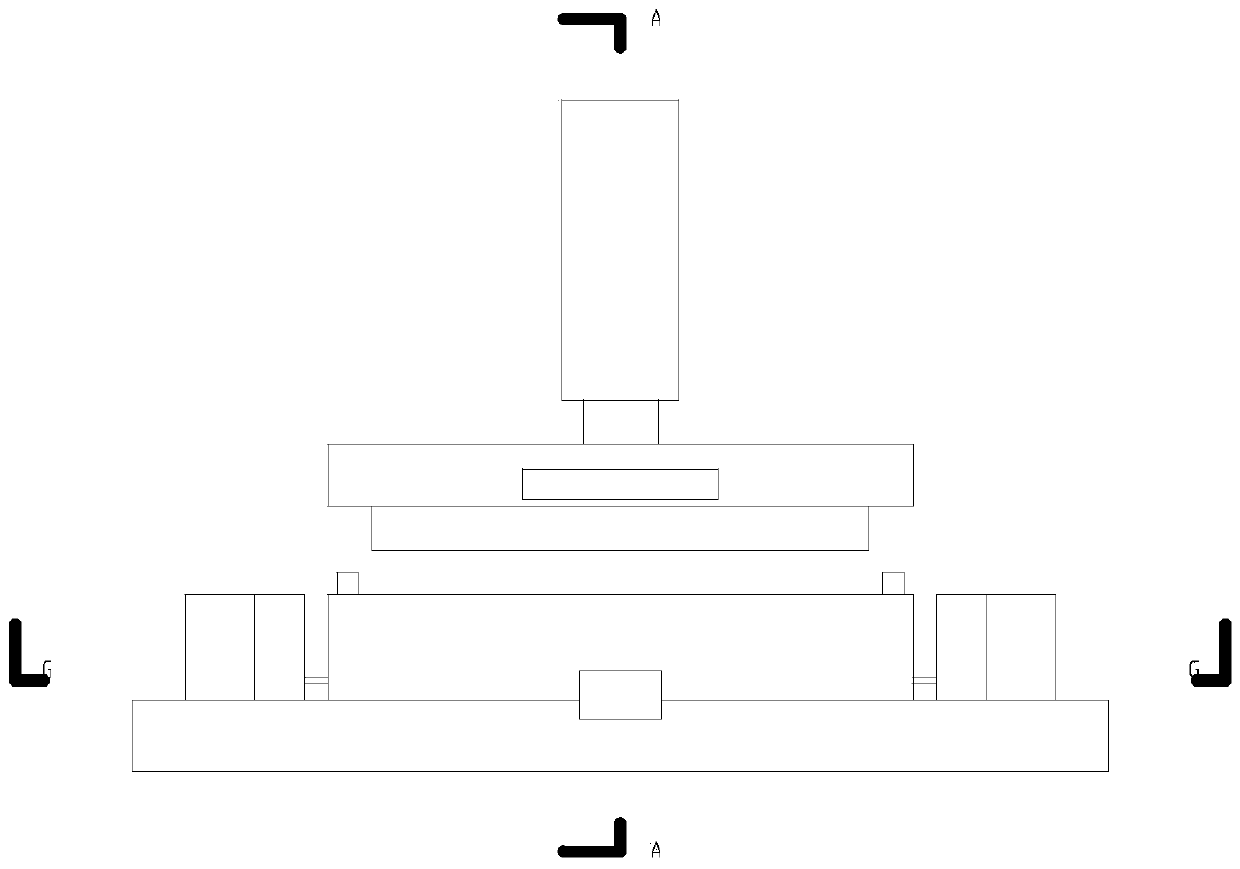

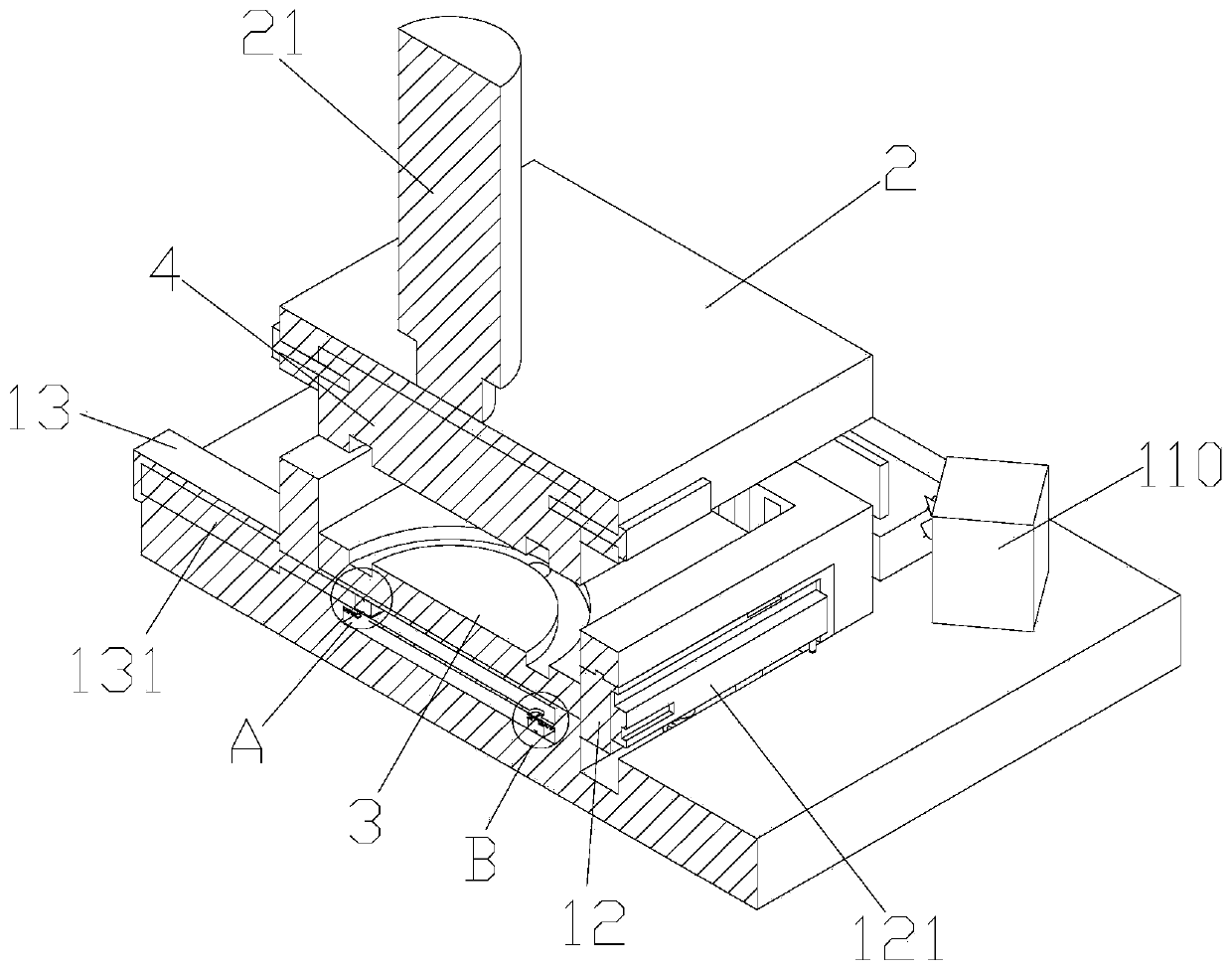

[0035] An optimized production method of a high-efficiency and low-noise axial flow fan, the axial flow fan includes a housing, an impeller, a motor and a ring, the ring is sleeved on the impeller blades, and the high-efficiency and low-noise axial flow The optimized production method of the fan includes: a. Parts production: processing the shell and blades separately, and the blades are assembled into an impeller; b. Ring processing: using a casting machine to directly process the ring to obtain a ring of the required specification; c. Parts assembly: Put the motor into the casing, then put the impeller on the output shaft of the motor, and finally put the ring on the impeller blades to complete the processing of the axial flow fan.

[0036] Adding a circular ring behind the blade of the fan impeller along the airflow direction reduces the loss of the circular surface caused by air friction and eddy current at the tip of the fan blade. Through a large number of CFD numerical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com