360-degree rotating single-point tin soldering device

A soldering and single-point technology, applied in the field of 360-degree rotating single-point soldering device, can solve the problems of multi-material, time-consuming and laborious, poor soldering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

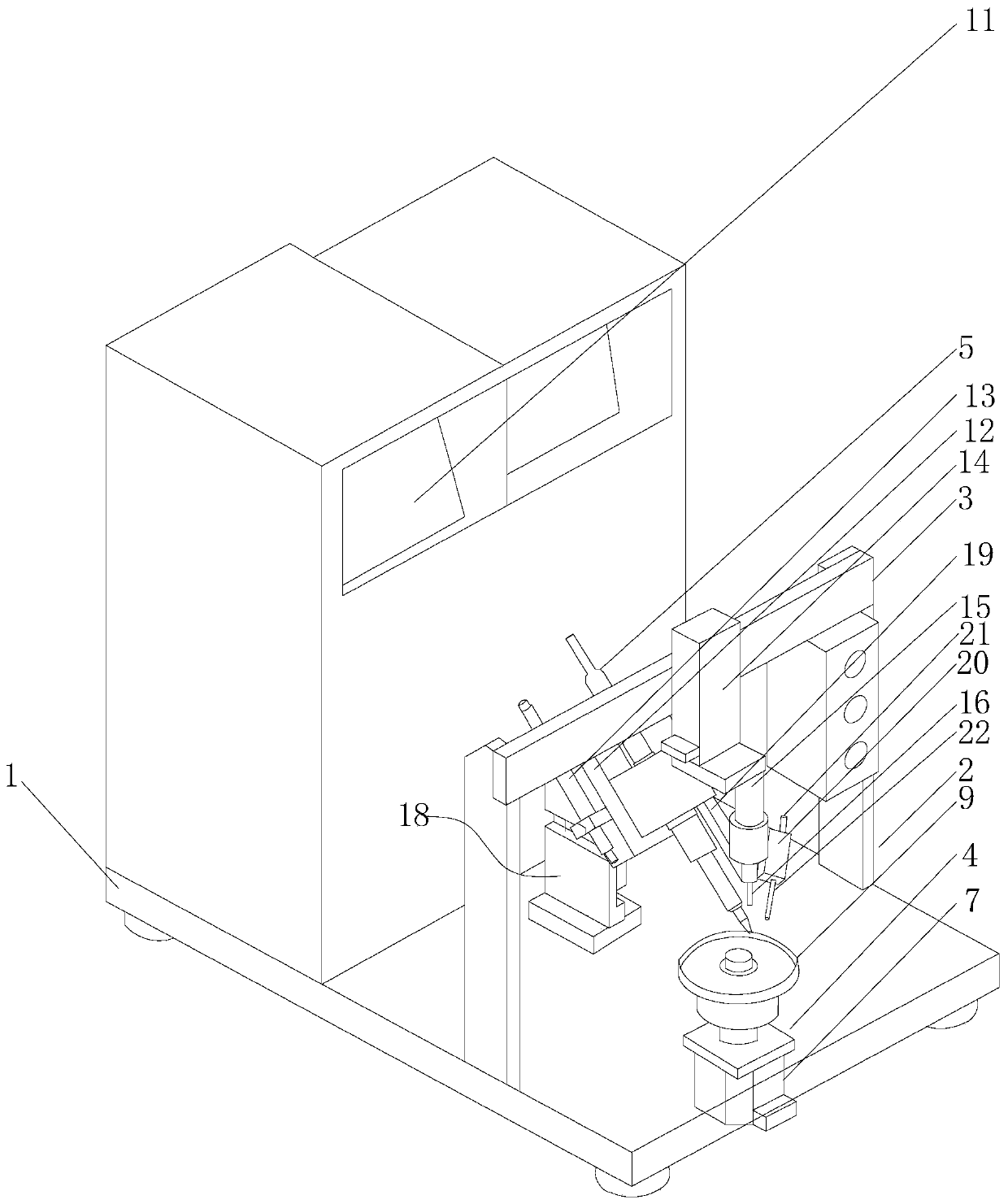

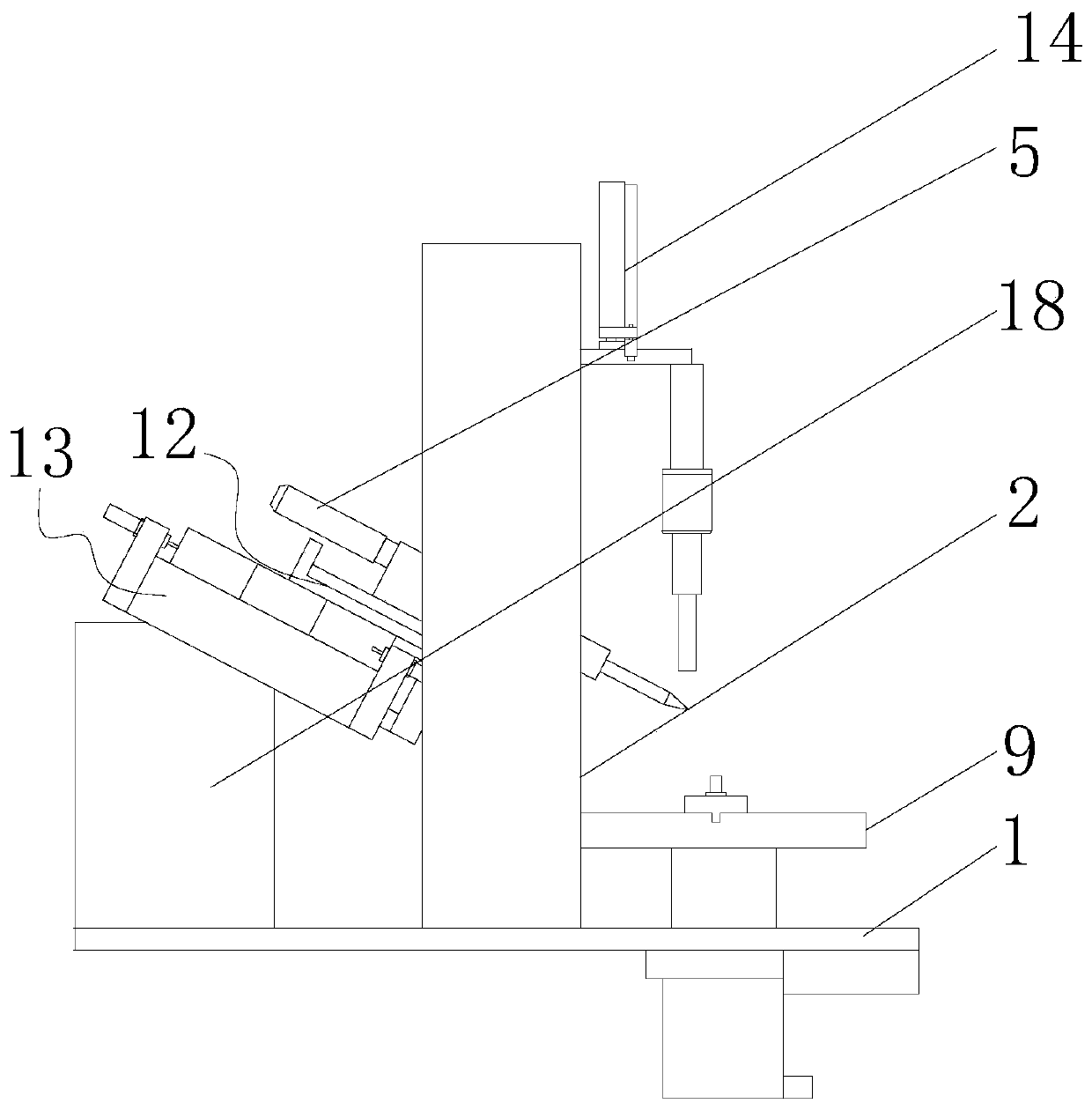

[0021] see Figure 1-2 As shown, the 360-degree rotating single-point soldering device includes a substrate 1, one end of the substrate is provided with a tin-feeding device and an automatic tin-feeding electric soldering iron, and the other end is provided with a rotating turntable; An inverted U-shaped bracket 2 is provided; the automatic tin-feeding electric soldering iron (automatic tin-feeding soldering iron) includes a temperature controller 11 and a metal handle 5 connected to the temperature controller; the rotary turntable is arranged on the edge of the substrate at the front end of the inverted U-shaped bracket On the top of the rotary turntable, the upper fixture assembly is installed on the inverted U-shaped bracket crossbar 3; the base plate between the U-shaped bracket and the tin feeding device is provided with a support 18, which passes through the slide cylinder The components are fitted with metal handles. The tin feeding device sends the tin wire to the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com