Enhanced environment-friendly composite fiber friction material and friction lining formula preparation process and device

A composite fiber and friction material technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of inconvenient cutting, the noise is difficult to match with the brake disc, and the quality of the finished product is reduced, so as to facilitate the cutting work and the operation. Control, easy to use and comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

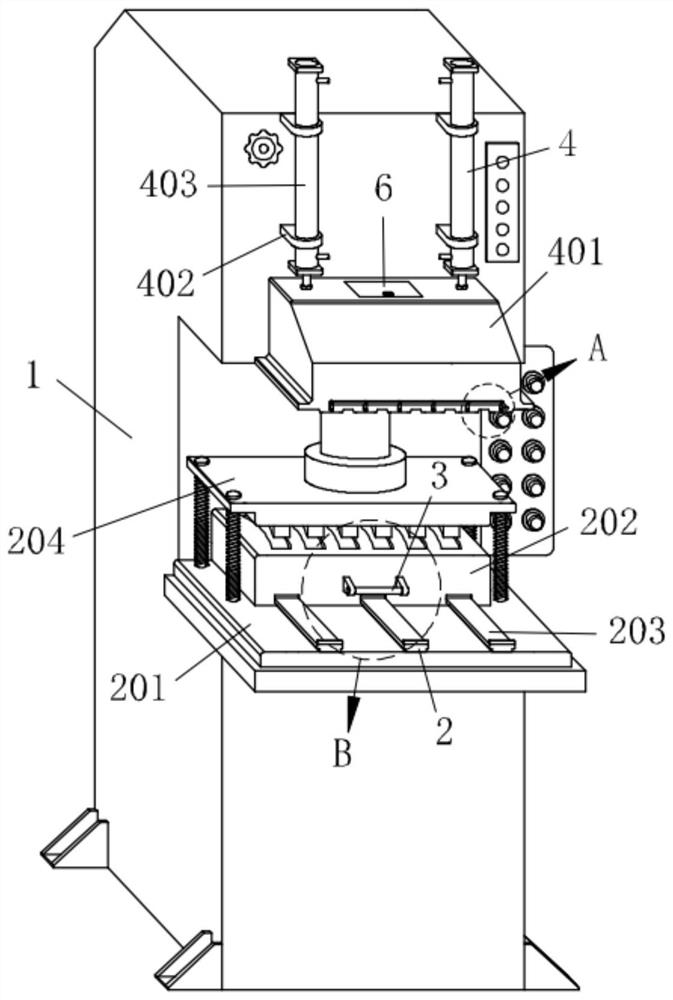

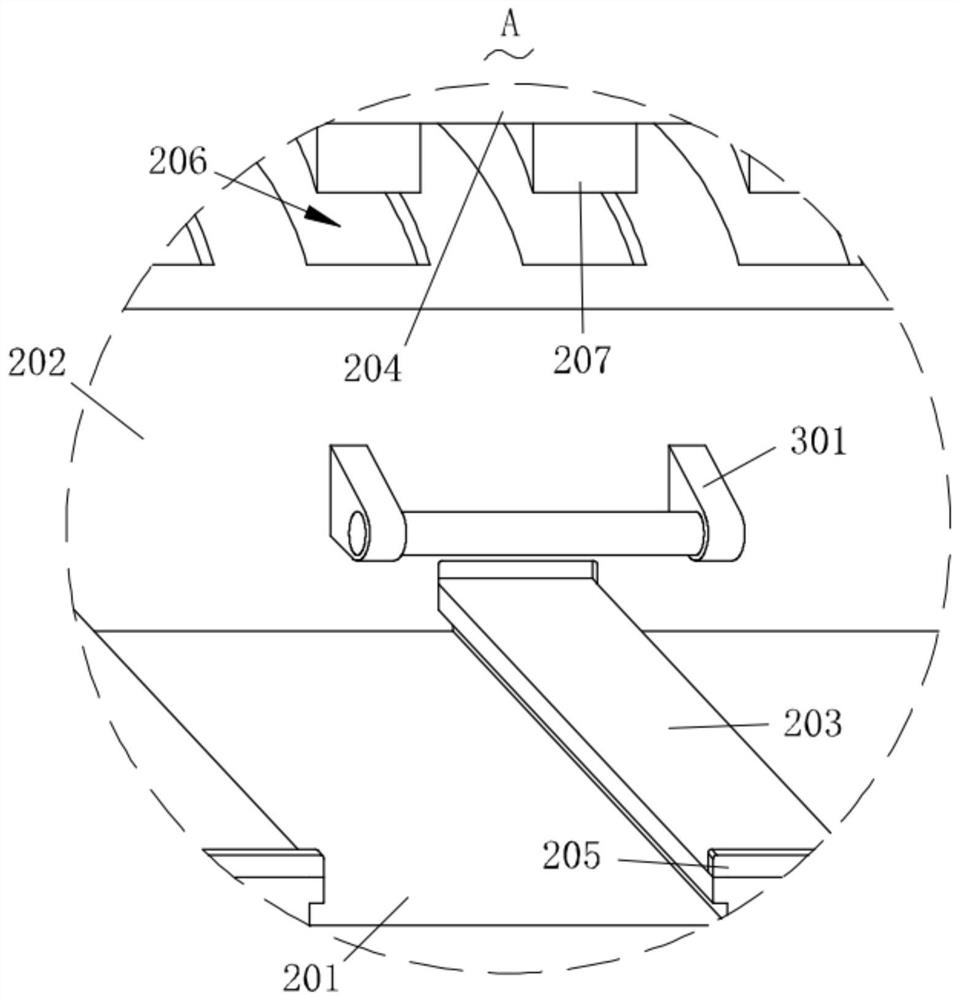

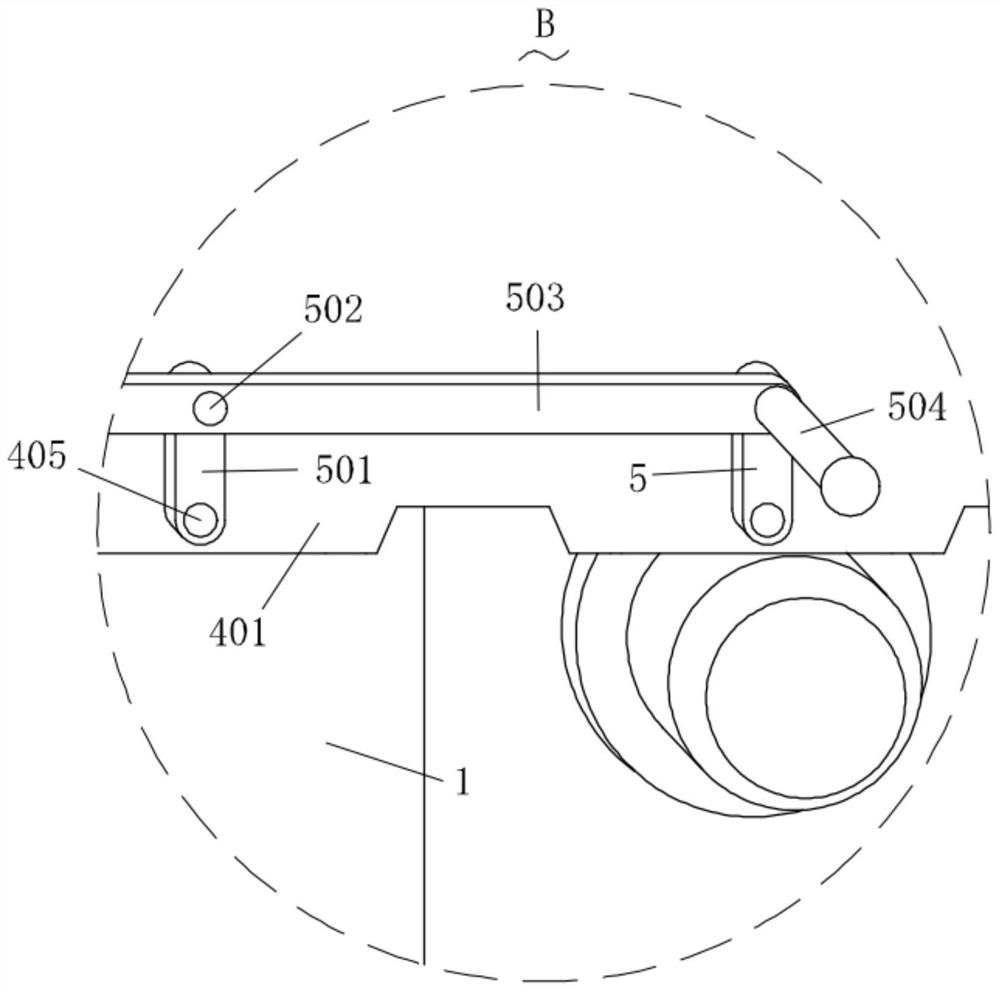

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0040] Such as Figure 1-Figure 6 As shown, the preparation process of the reinforced environmentally friendly composite fiber friction material and friction lining of the present invention includes the following raw materials: 6kg of ceramic fiber, 18kg of steel wool fiber, 7kg of mineral fiber, 9kg of phenolic resin, 4kg of rubber elastic particles, Graphite 3kg, light calcium oxide 9kg, aramid pulp 2kg, titanate 2kg, calcium carbonate 9kg, calcined alumina 6kg, red copper fiber 8kg, red copper powder 4kg, calcined petroleum coke 10kg, zircon powder 3kg, environmental protection composite fiber Material 20g;

[0041] The preparation process is as follows:

[0042] S1. Take raw materials according to the proportion: ceramic fiber, steel wool fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com