Laser 3D (three-dimensional) printing device with multiple inkjet heads

A 3D printing and multi-nozzle technology, which is applied in the field of multi-nozzle laser 3D printing equipment, can solve problems such as the inability to use metal parts to form, reduce the efficiency of 3D printing, and affect the effect of 3D printing, so as to achieve the effect of improving the effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

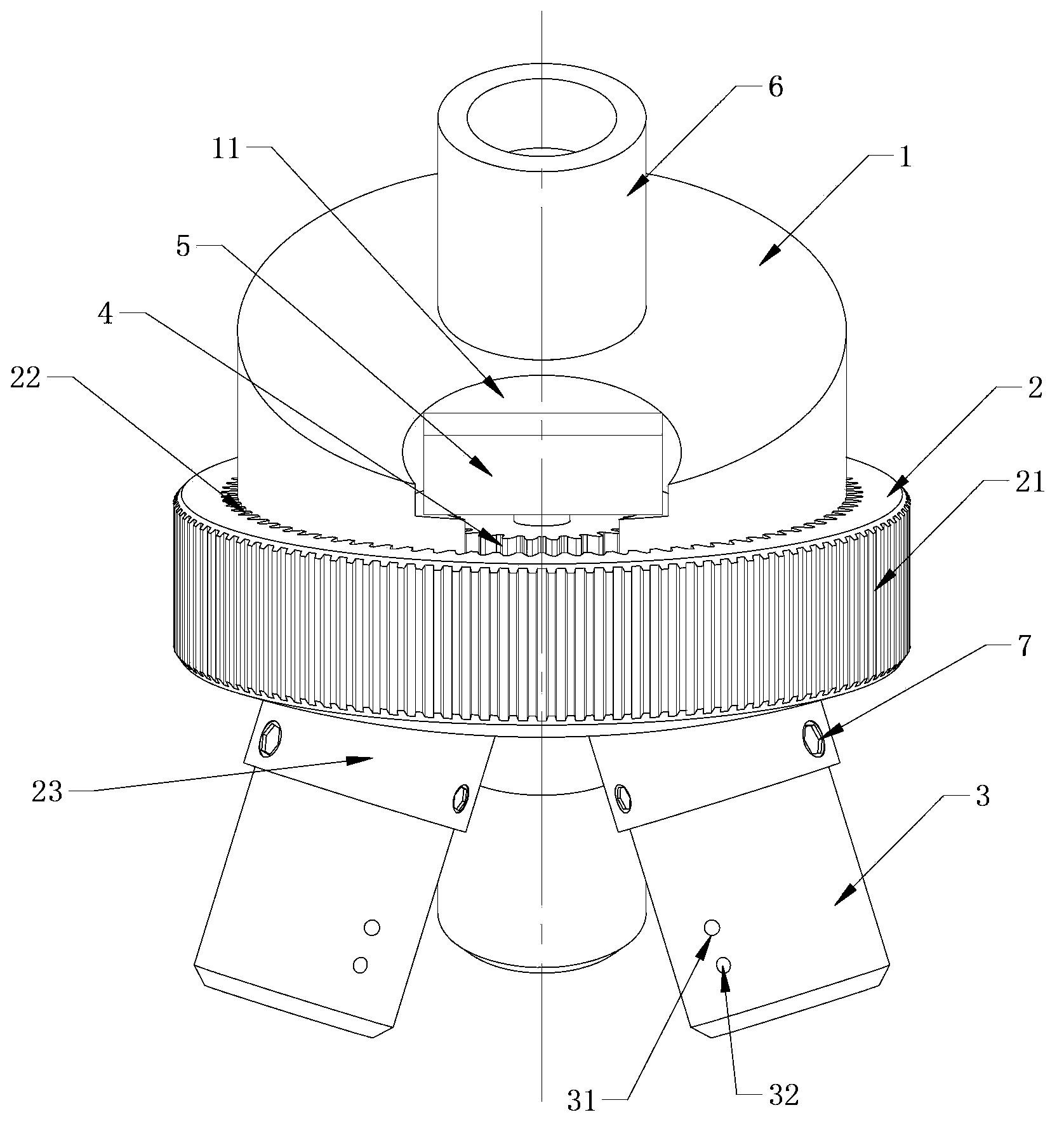

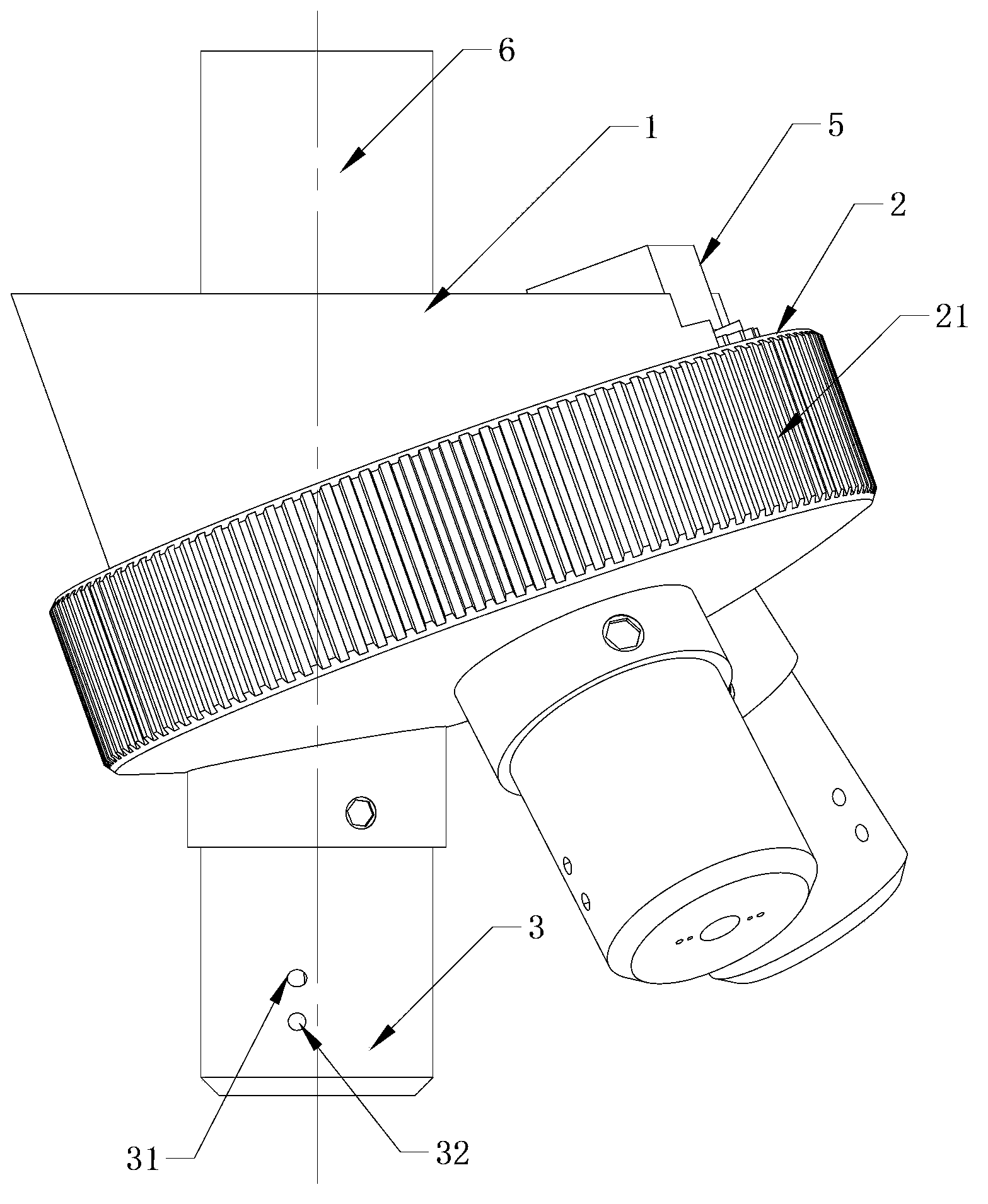

[0027] Such as figure 1 , figure 2 As shown, a multi-nozzle laser 3D printing equipment includes a laser generator, a laser nozzle, a mechanical arm, a workbench and a control system for controlling the entire printing equipment. None of them are shown; the laser generator can be a fiber laser generator or a carbon dioxide laser generator. The laser nozzle is installed on the robot arm, and the control system controls the robot arm to freely move horizontally and vertically around the workbench, while the laser nozzle is driven by the robot arm to perform 3D printing on the workbench.

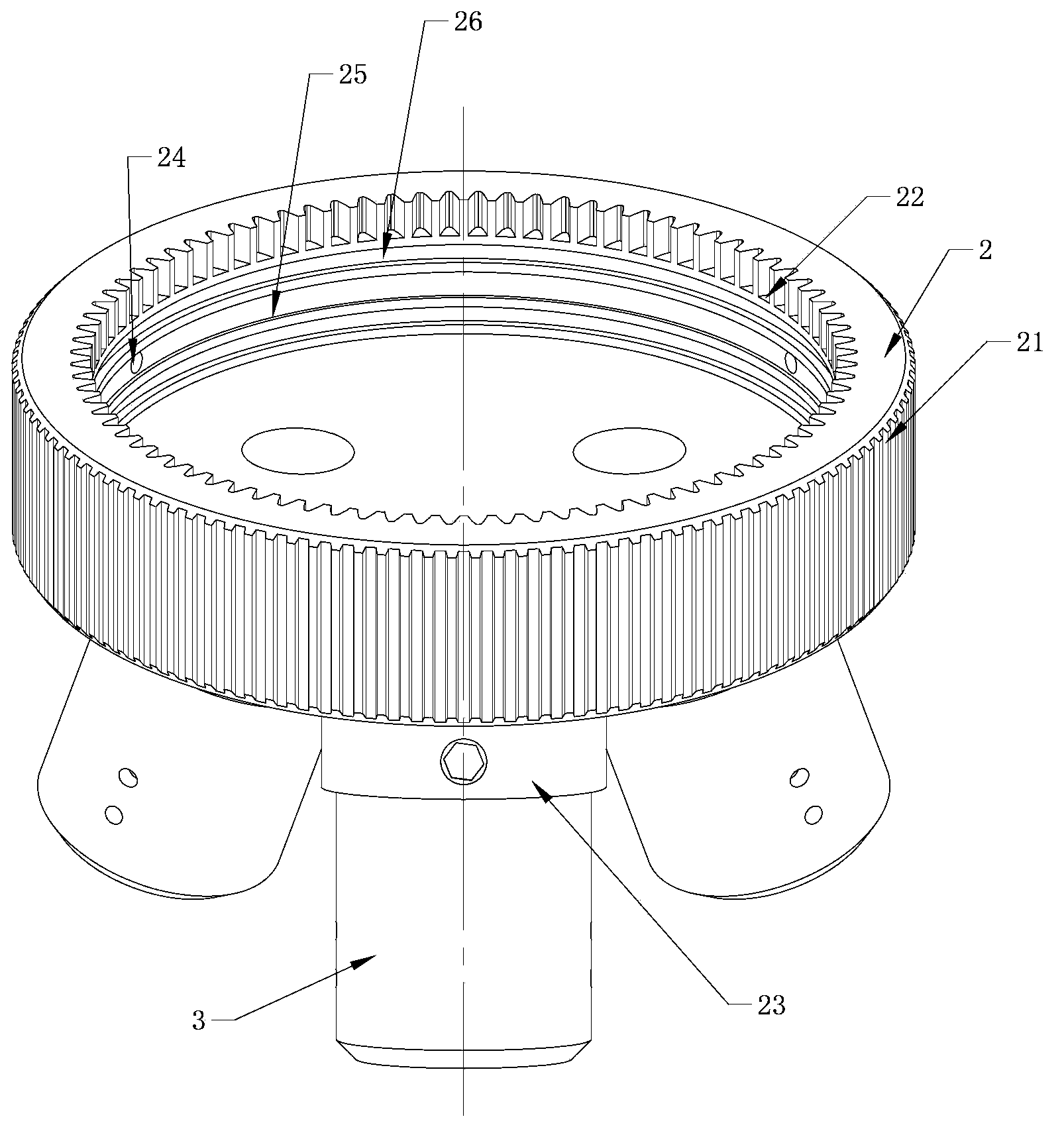

[0028] Such as image 3 As shown, the laser spray head includes a laser head and a powder spray head 3 assembly, and the powder spray head assembly includes a connecting seat 1, a turntable 2, and at least two powder spray heads 3, such as Figure 4As shown, the connecting seat 1 is cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com