Anti-deformation welding process for large and long box-shaped structural part

A technology of welding process and structural parts, which is applied in the field of anti-deformation welding process, can solve the problems of reducing the level requirements of welding operators and labor intensity, and achieve the effect of smooth appearance, reducing level requirements and preventing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

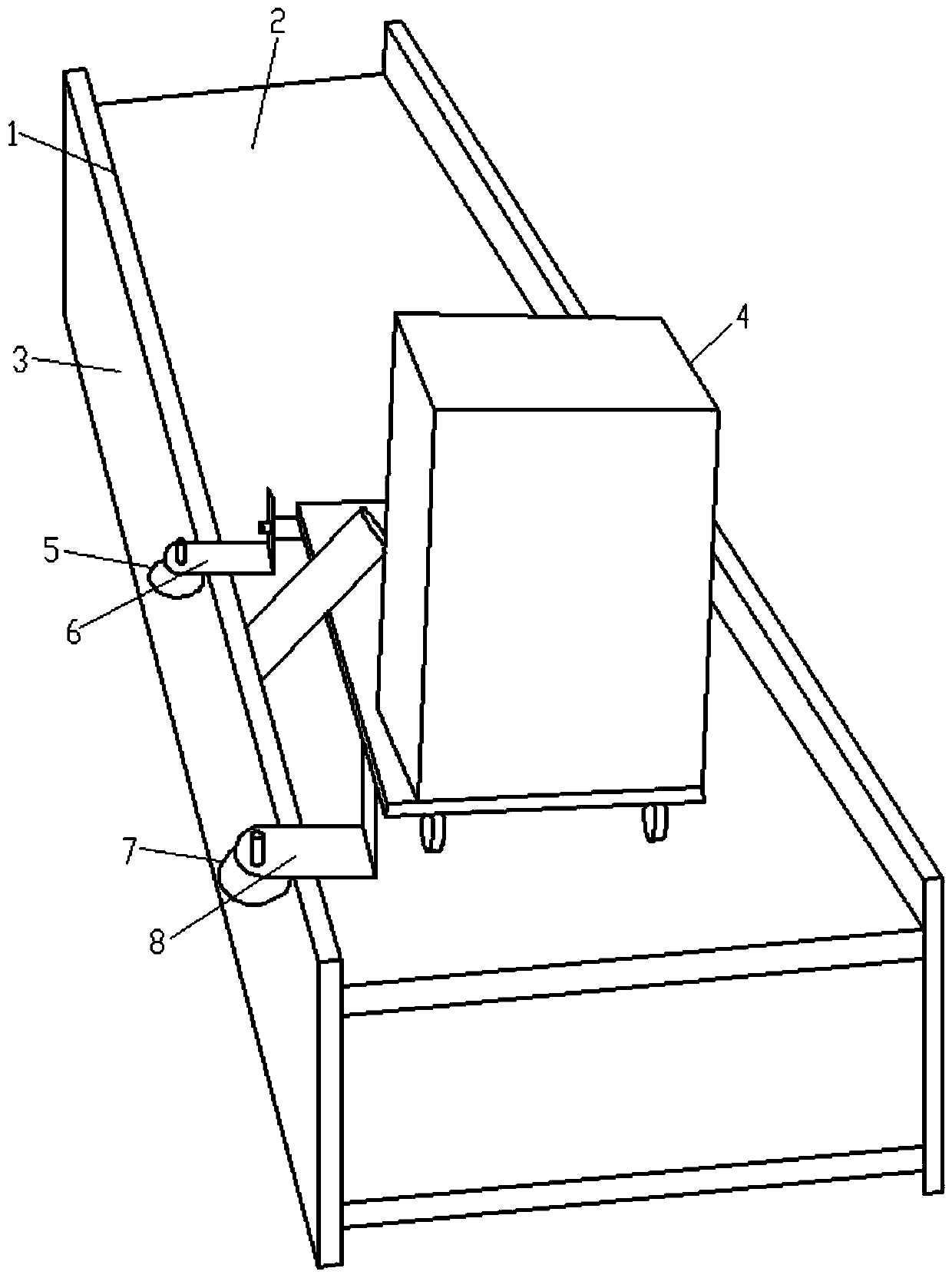

[0021] The following will be combined with Figure 1-5 The specific embodiments shown are used to describe the present invention in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

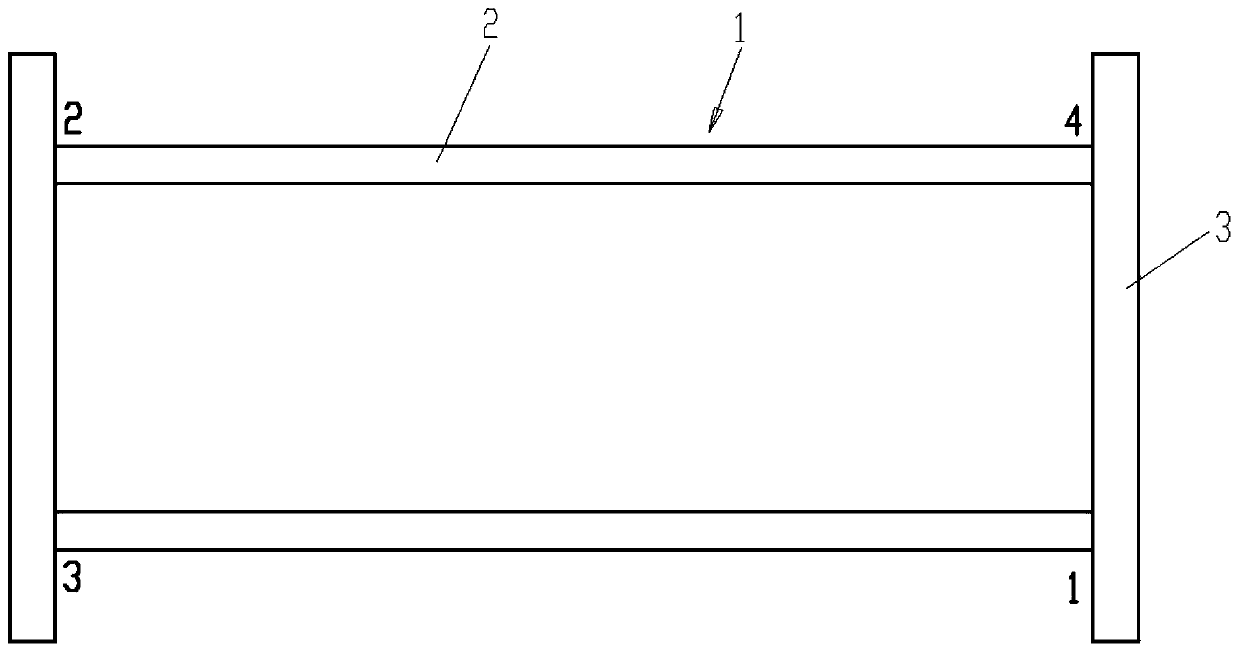

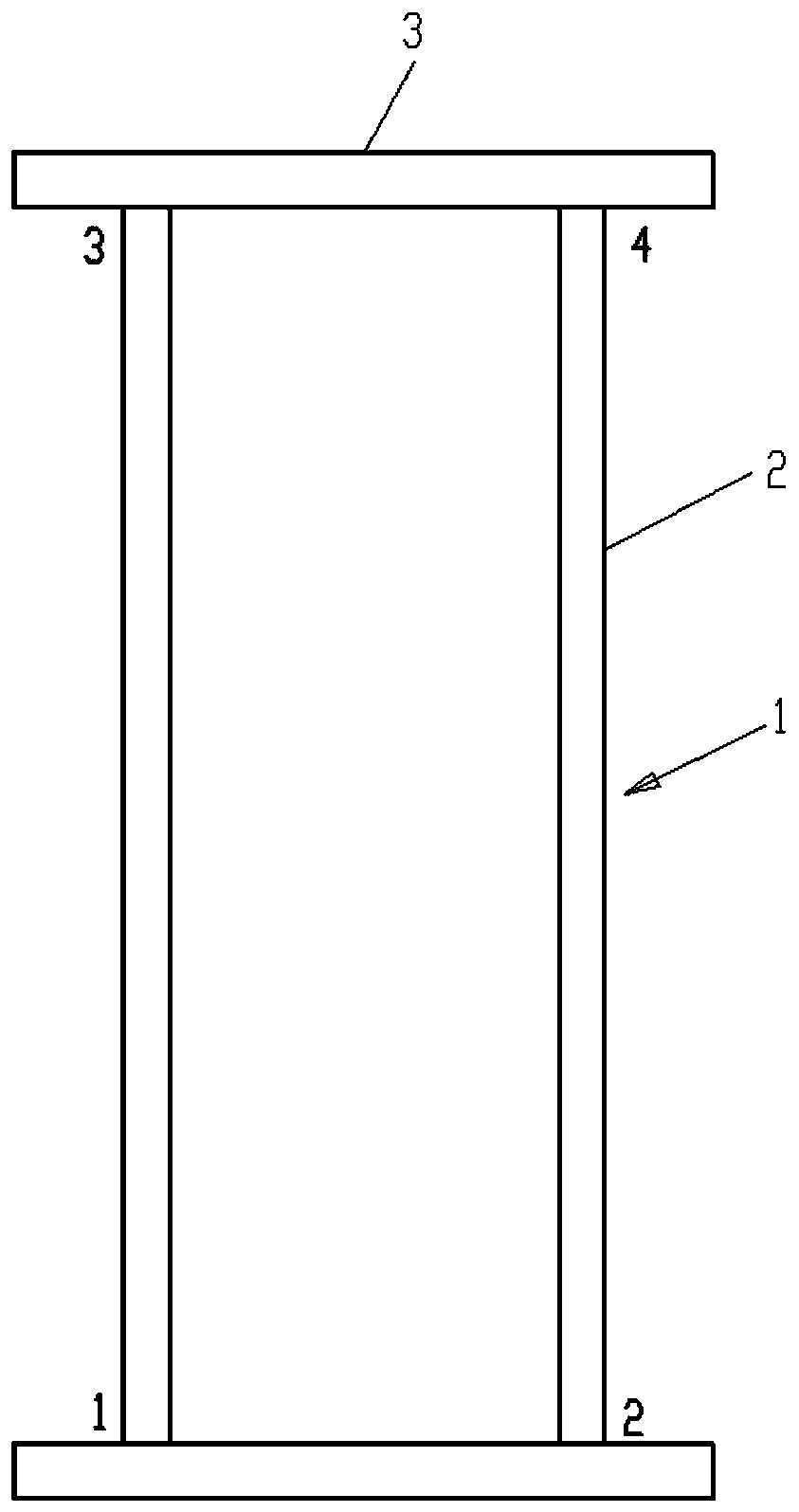

[0022] The anti-deformation welding process for large and long box-shaped structural parts includes the following steps; figure 1 and 2 as shown,

[0023] 1) Adjust the position of the large and long box-shaped structural part: place the large and long box-shaped structural part 1 formed by the combination of the vertical plate 2 and the cover plate 3 horizontally according to the vertical plate 2;

[0024] 2) Adjust the welding method: take the weld seam as the benchmark, the weld seam as the benchmark here is a set of weld seams to be welded, and use the upper end surface of the vertical plate 2 as the walking support surface of the semi-automatic welding trolley 4, so that the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap