A pipeline welding machine

An internal welding machine and pipeline technology, which is applied in welding equipment, tubular objects, auxiliary welding equipment, etc., can solve the problems of low bending capacity, loose internal welding machine and pipeline, and inability to adapt to the small curvature radius of the bending pipe. , to achieve the effect of improving adaptability, meeting the requirements of walking stability, and meeting the requirements of large-slope crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

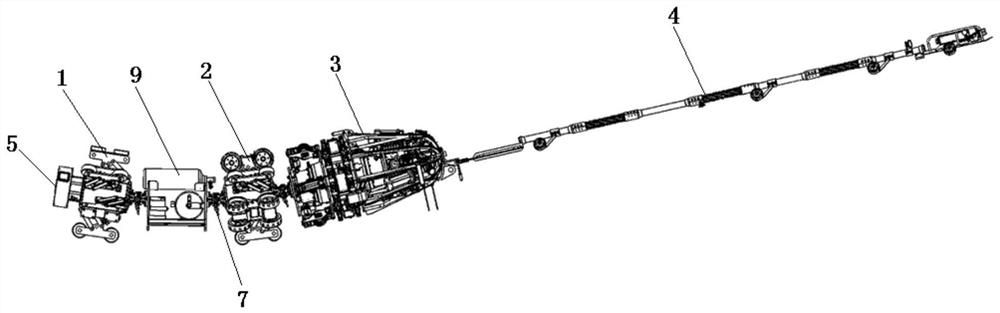

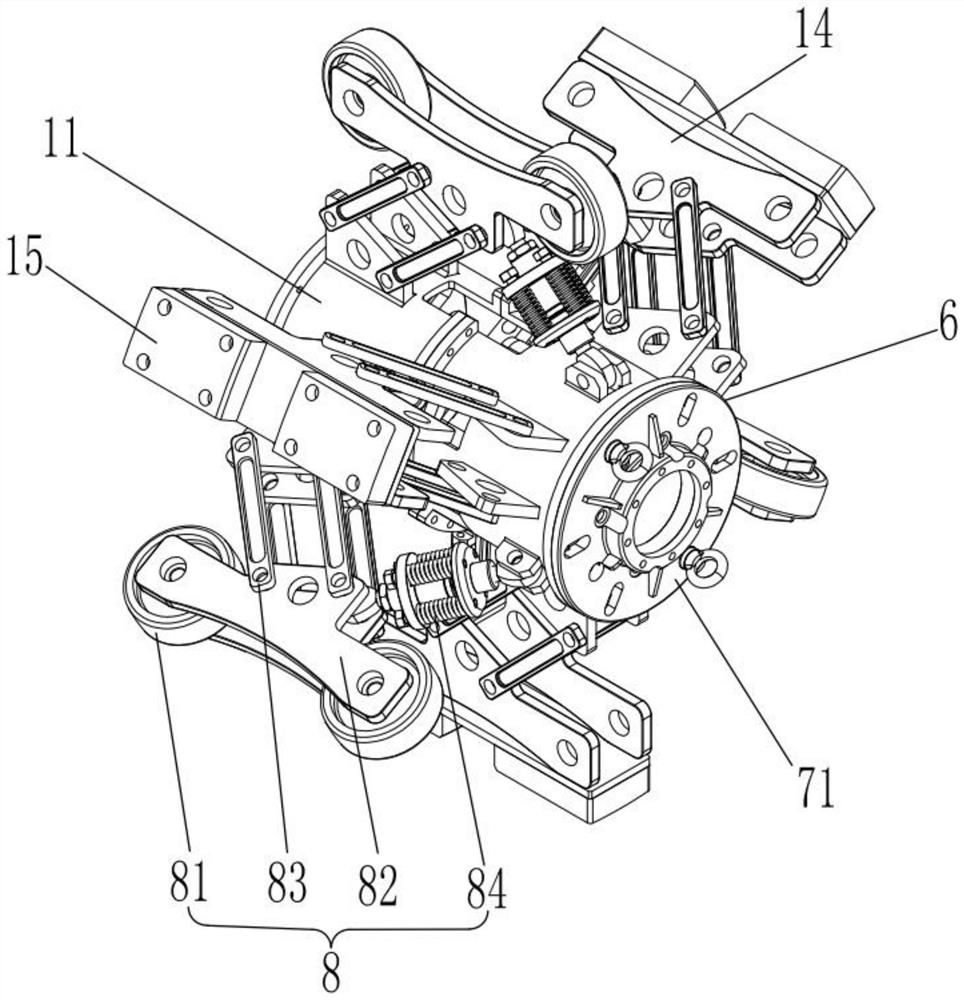

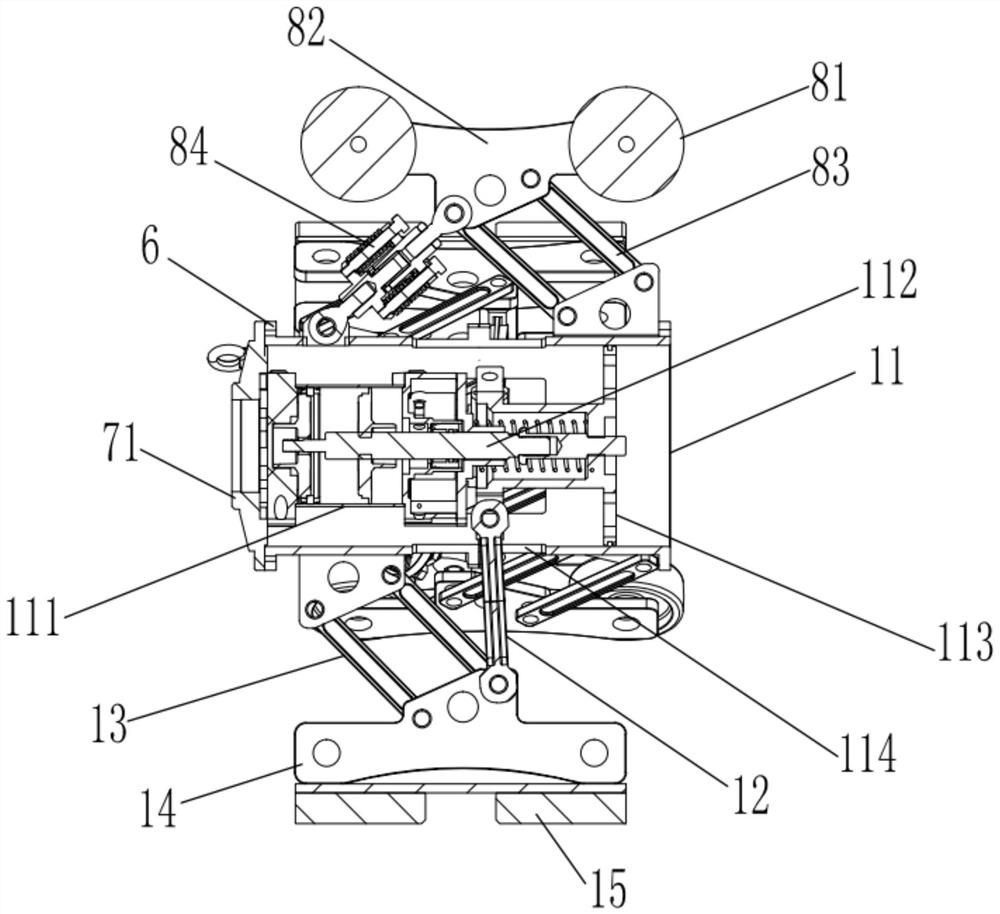

[0048] The specific embodiment of the present invention is as Figure 1-11 As shown, a pipeline internal welding machine includes a braking module 1 , an internal welding machine energy module 9 , a driving module 2 and a welding machine module 3 sequentially connected through a flexible connection mechanism 7 . Wherein, the end faces of each module are provided with connecting flanges 6 for installing flexible connecting mechanisms 7 . By flexibly connecting each module of the internal welding machine, the whole set of internal welding machine equipment can perform adaptive posture adjustment according to the bending changes of the pipeline when walking in the pipeline. At the same time, the flexible connection of each module can enable the internal welding machine to meet the passage requirements when the curvature radius of the pipeline is small, thereby improving the adaptability of the internal welding machine to the changing pipeline, that is, the bending ability.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com