Welding equipment for circuit breaker and welding platform using same

A welding equipment and welding platform technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, unhealthy workers, low welding efficiency, etc., to achieve reasonable structure and ensure welding quality. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

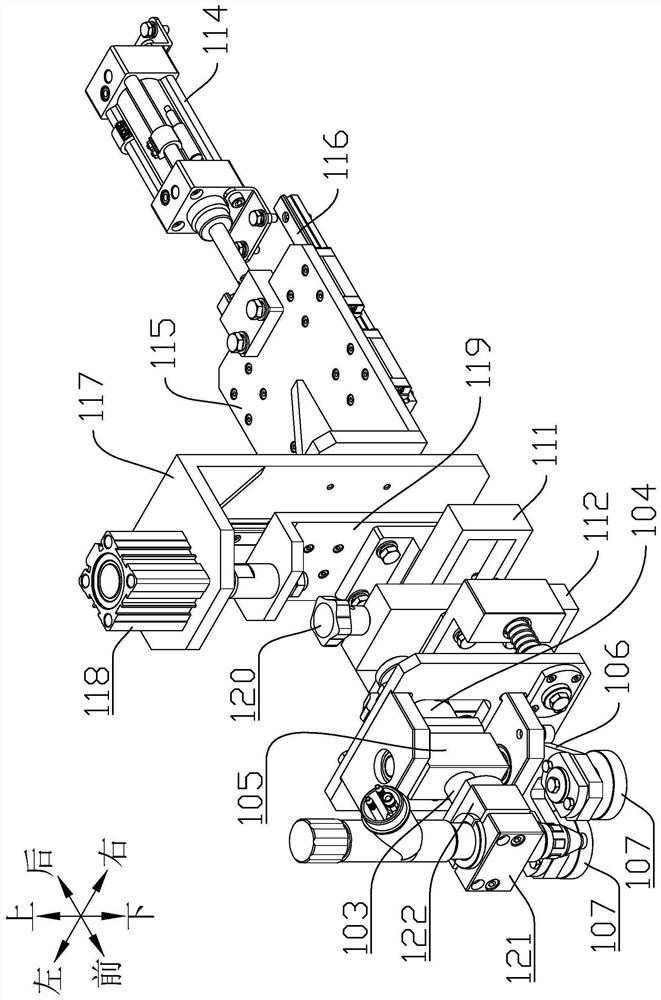

[0025] Combine below Figure 1 to Figure 9 The present invention is further described.

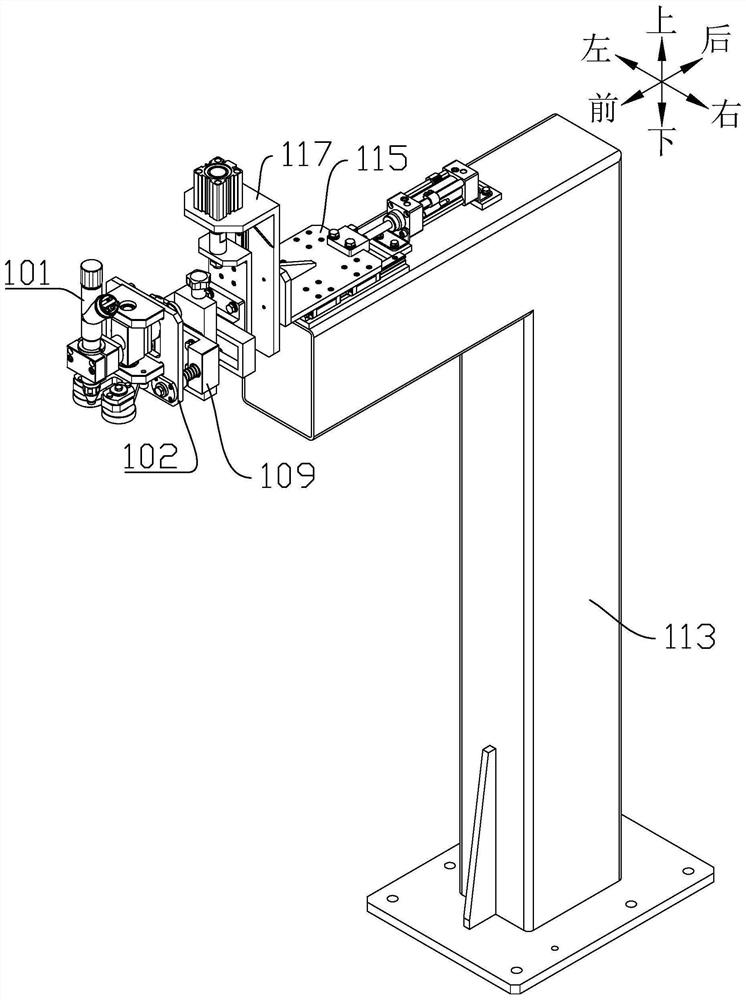

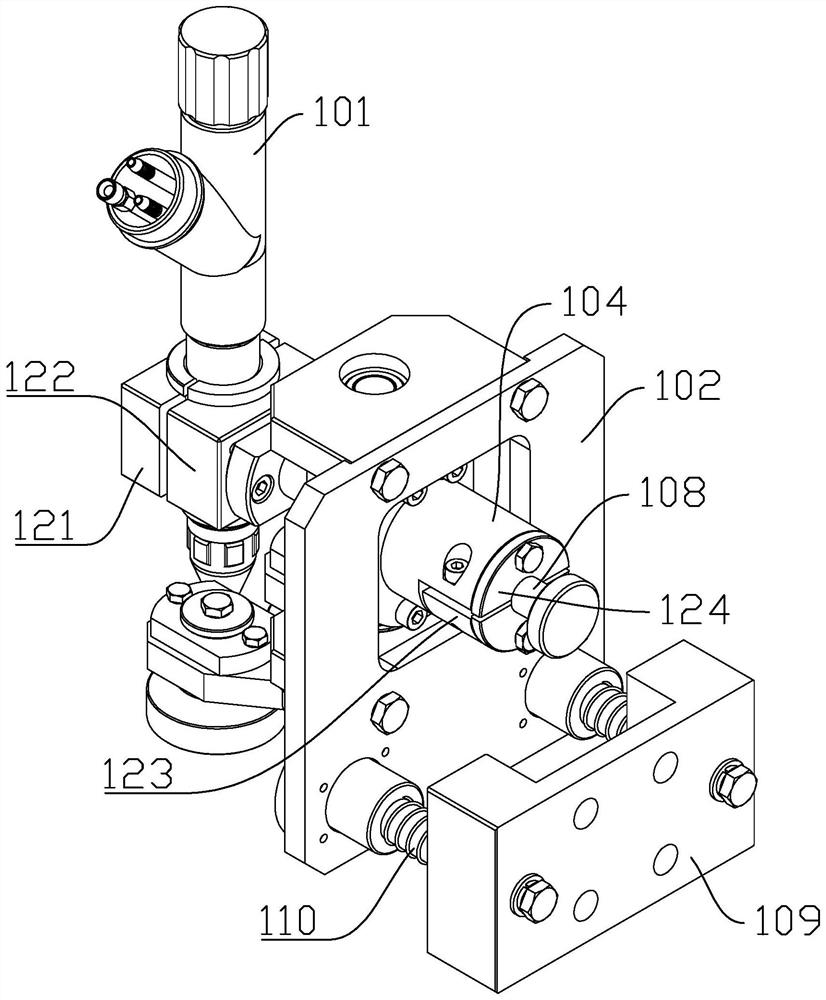

[0026] The present invention relates to a welding device for a circuit breaker, which includes a torch clip assembly for installing a welding torch 101, and the welding device also includes a feed mechanism for moving the torch clip assembly, and the feed mechanism is arranged on a support column 113 .

[0027] The feed mechanism includes at least one of a vertical feed assembly and a horizontal feed assembly, the vertical feed assembly is used to move the gun clip assembly up and down, and the horizontal feed assembly is used to move the gun clip assembly back and forth.

[0028] The horizontal feed assembly comprises a horizontal feed cylinder 114, a horizontal feed slide plate 115 and a horizontal feed guide rail 116, and the push rod of the horizontal feed cylinder 114 pushes the horizontal feed slide plate 115 to move along the horizontal feed guide rail 116, and the horizontal feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com