Wastewater treatment equipment for grinding meat processing substances and cleaning oil stains

A meat processing and wastewater treatment technology, applied in animal processing wastewater treatment, water/sewage treatment equipment, water/sewage treatment, etc. The effect of avoiding foul odor and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

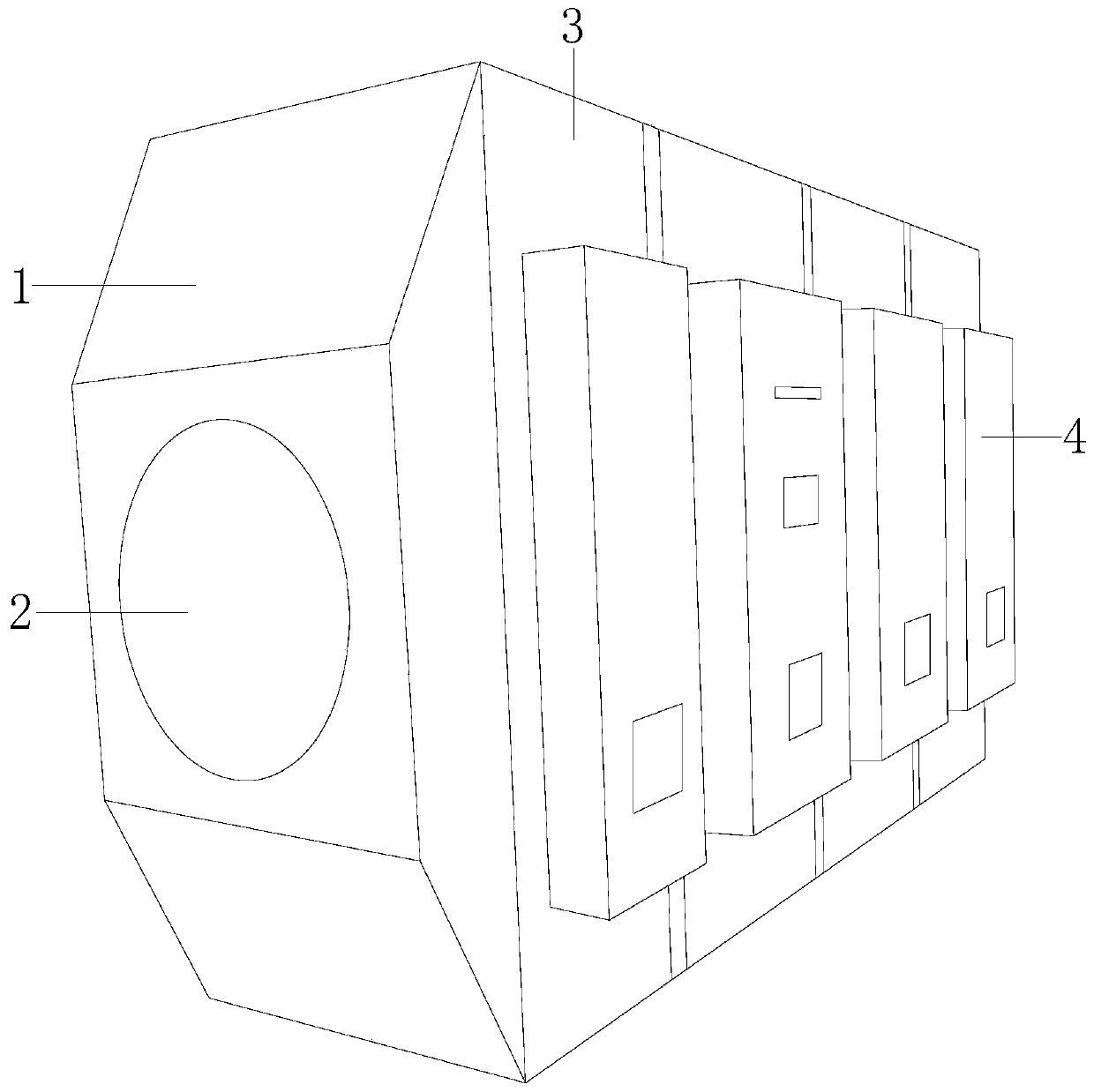

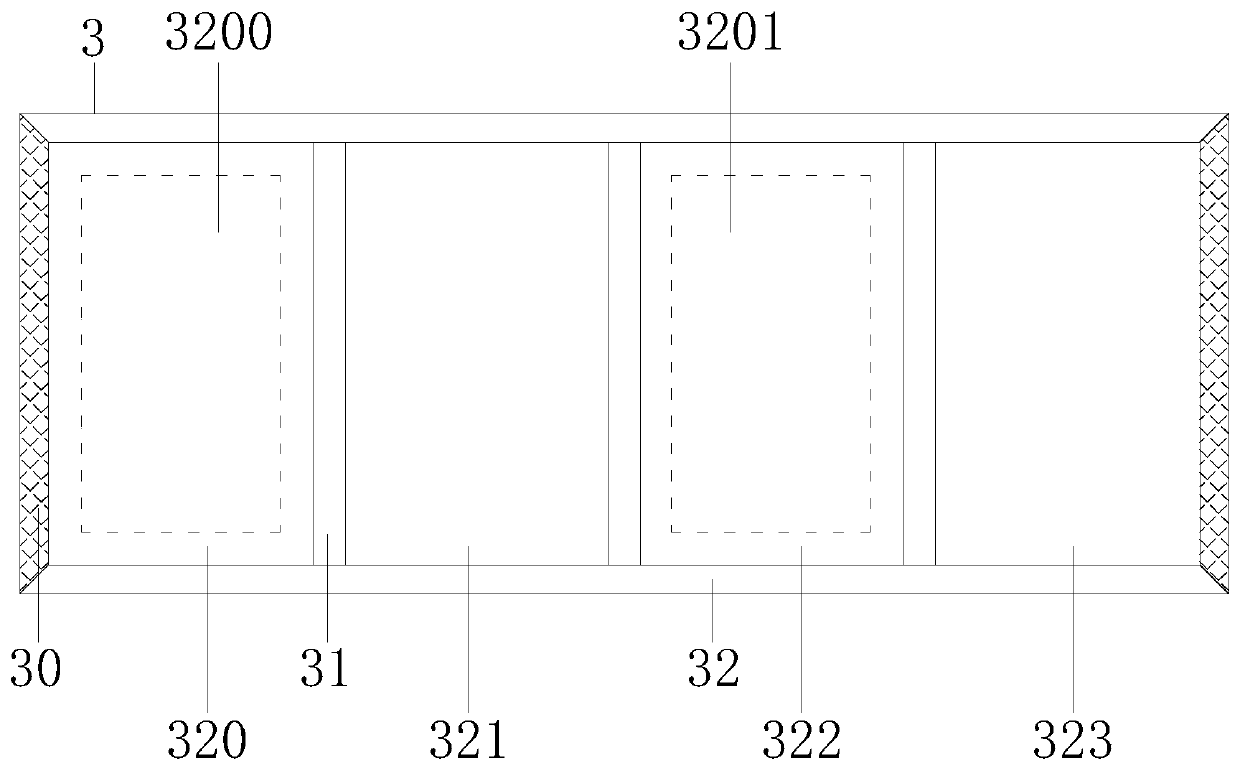

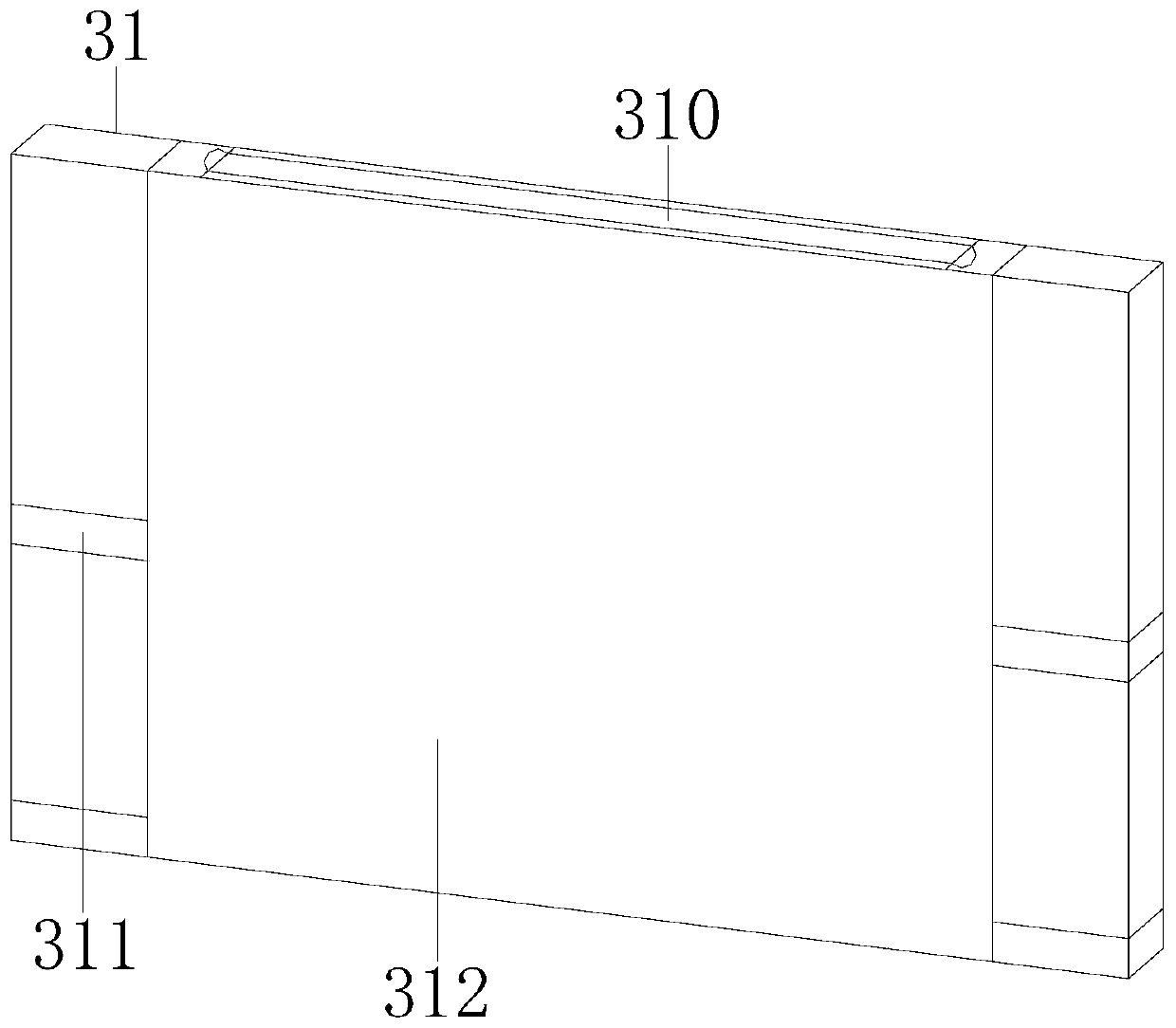

[0027] Example 1 see Figure 1-6 , the present invention provides a technical scheme of waste water treatment equipment for crushing meat processing substances and cleaning oil stains: its structure includes a front cover port 1, a sewage inlet 2, a sewage treatment tank 3, and a movable door 4. The front cover port 1 is provided with Sewage inlet 2, the front cover 1 is welded to the sewage treatment tank 3, and the sewage treatment tank 3 is installed and connected to the movable door 4, and the movable door 4 is used not only for controlling the equipment but also for controlling the sewage treatment tank 3 Assembled and fixed, the utilization rate is high, and described sewage treatment box 3 comprises side plate 30, dividing plate 31, processing frame 32, and described side plate 30, dividing plate 31 are installed and connected with processing frame 32, and described dividing plate 31 can Disassemble and assemble, and reduce the volume of the equipment when the amount of...

Embodiment 2

[0029] Example 2 see Figure 7-8, the present invention provides a technical scheme of waste water treatment equipment for crushing meat processing substances and cleaning oil stains: the solid-liquid device 3201 in its structure includes a solid-liquid separation frame 70, a main cylinder 71, a filter frame 72, and a depth filter 73. Solid-liquid separation frame 70 is equipped with main cylinder 71, filter frame 72, depth filter 73, and described filter frame 72 is adjacent to main cylinder 71, depth filter 73, and described main cylinder 71, filter frame 72, depth filter 73 are successive Advanced arrangement, orderly transmission, and good filtering effect. The main cylinder 71 includes an inner rod structure 710, a suspension rod 711, a hanging bar 712, and an outer cylinder 713. The inner rod structure 710 is embedded and connected with the outer cylinder 713. The suspension rod 711 is locked with the suspension bar 712, the suspension rod 711 is connected to the suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com