Ultrasonic humidifying device of paper machine

A humidifying device, ultrasonic technology, applied in the direction of wetting device, paper machine, paper making, etc., can solve the problems of poor processing and use, obvious difference between the two sides of the base paper, static electricity of the base paper, etc., to improve the hand feel, reduce delamination, reduce The effect of paper dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

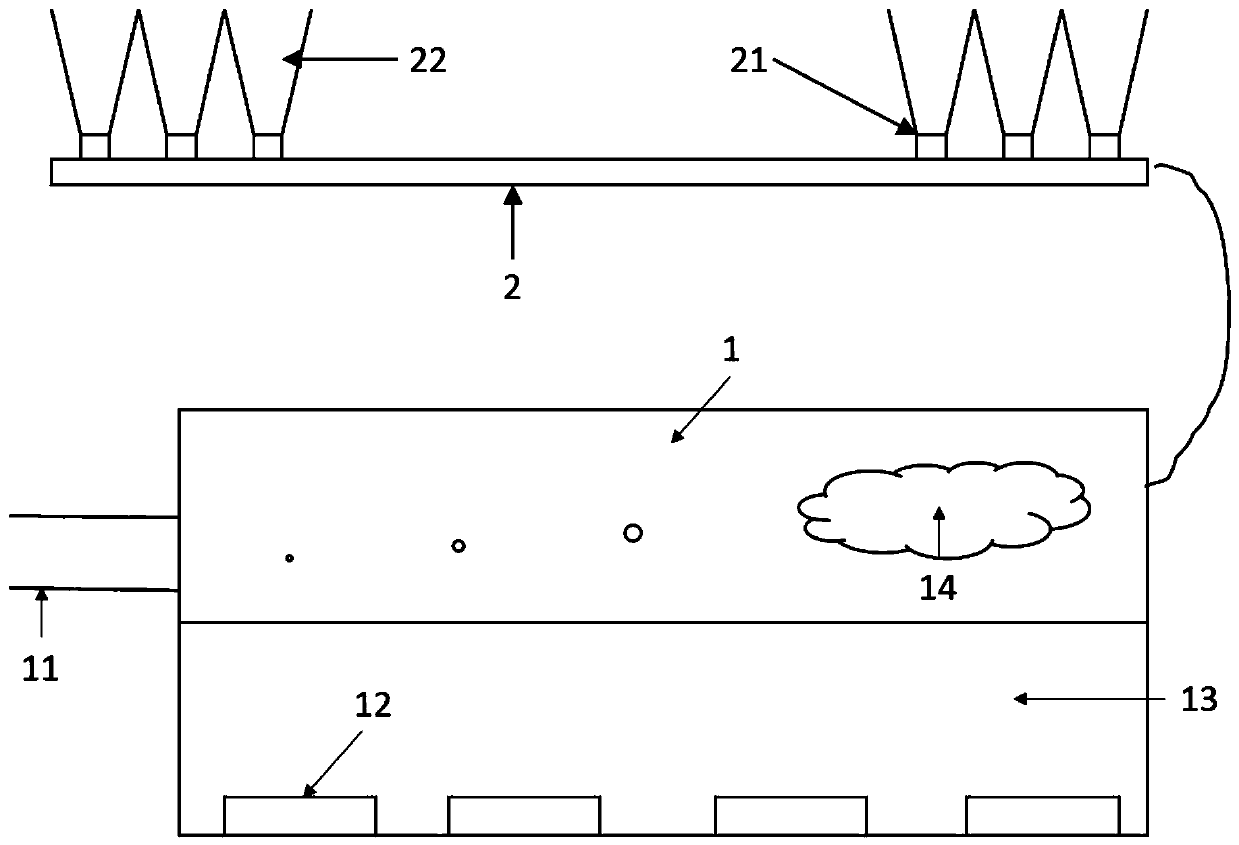

[0027] A paper machine ultrasonic humidifying device, such as figure 1 , the device comprises a water tank 1 connected by pipelines and a 3m long pipe 2, a water inlet pipe is provided at a height of 10cm on the side of the water tank 1, water can be added to the water tank at any time, and the water tank 1 includes clean water 13 and 8 clean water 13 The ultrasonic nebulizer 12 that vibrates to generate atomized water vapor 14 is arranged on the bottom of the water tank 1 , the clean water 13 is located in the water tank 1 , and the long tube 2 is provided with 27 air outlet holes 21 . The outside of the water tank 1 is provided with an air intake pipe 11 for supplying compressed air, and the air outlet 21 sprays out the high-pressure atomized water vapor 22 formed after the atomized water vapor 14 is pressurized by the compressed air. Wherein, the pipeline or the air inlet pipeline 11 is a hose, and the hose is selected for more flexible operation, and the position of humidi...

Embodiment 2

[0030] The difference from Embodiment 1 is that the air outlet 21 on the long tube 2 is a shower head with a diameter of 8 mm, and the shower head is provided with 25 small holes with a diameter of 0.8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com