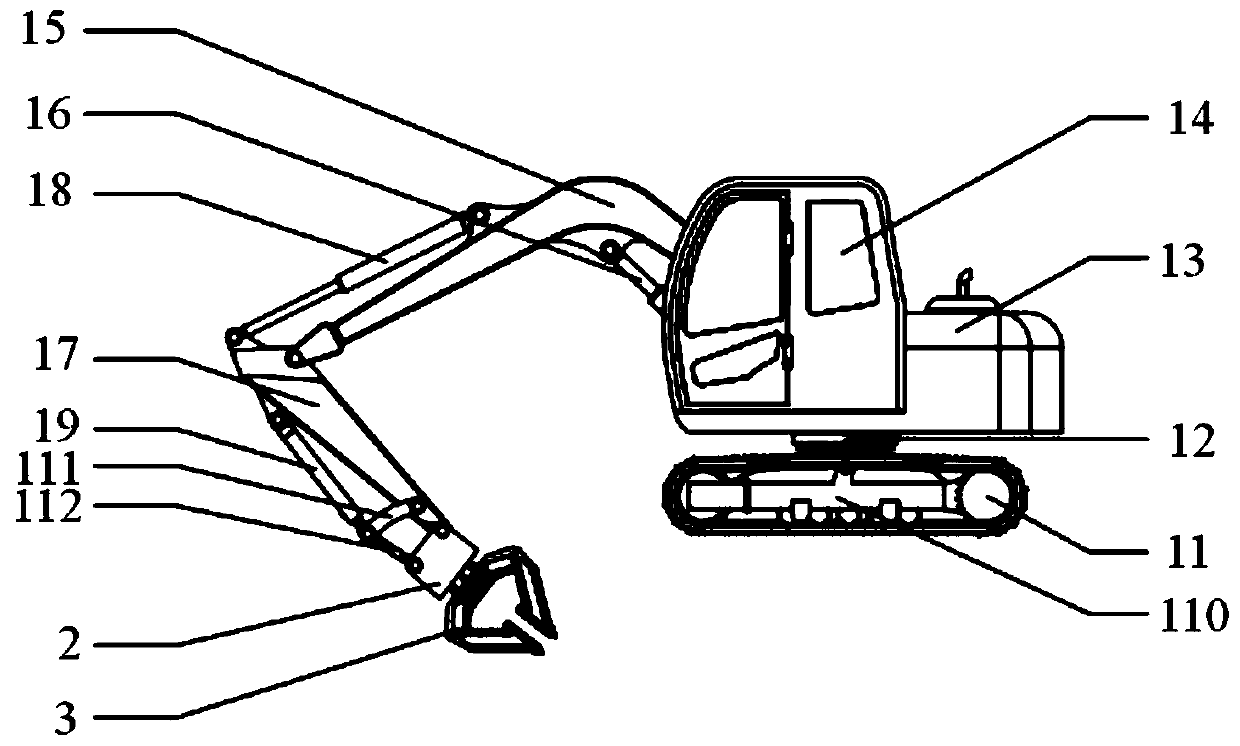

Automatic kerb laying machine based on excavator platform

An automatic laying and excavator technology, which is applied to roads, roads, road repairs, etc., can solve the problem that the auxiliary vehicle is not very convenient to move, and achieve the effect of improving the efficiency of laying, saving resources, and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation is as follows:

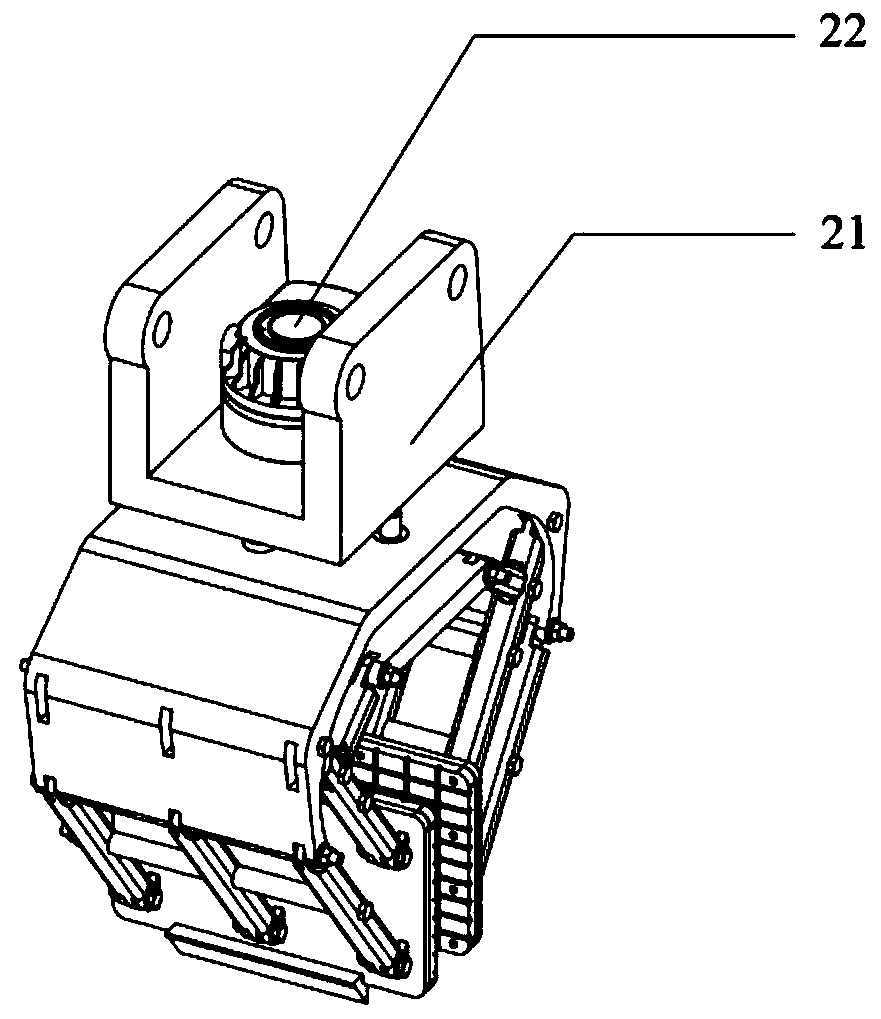

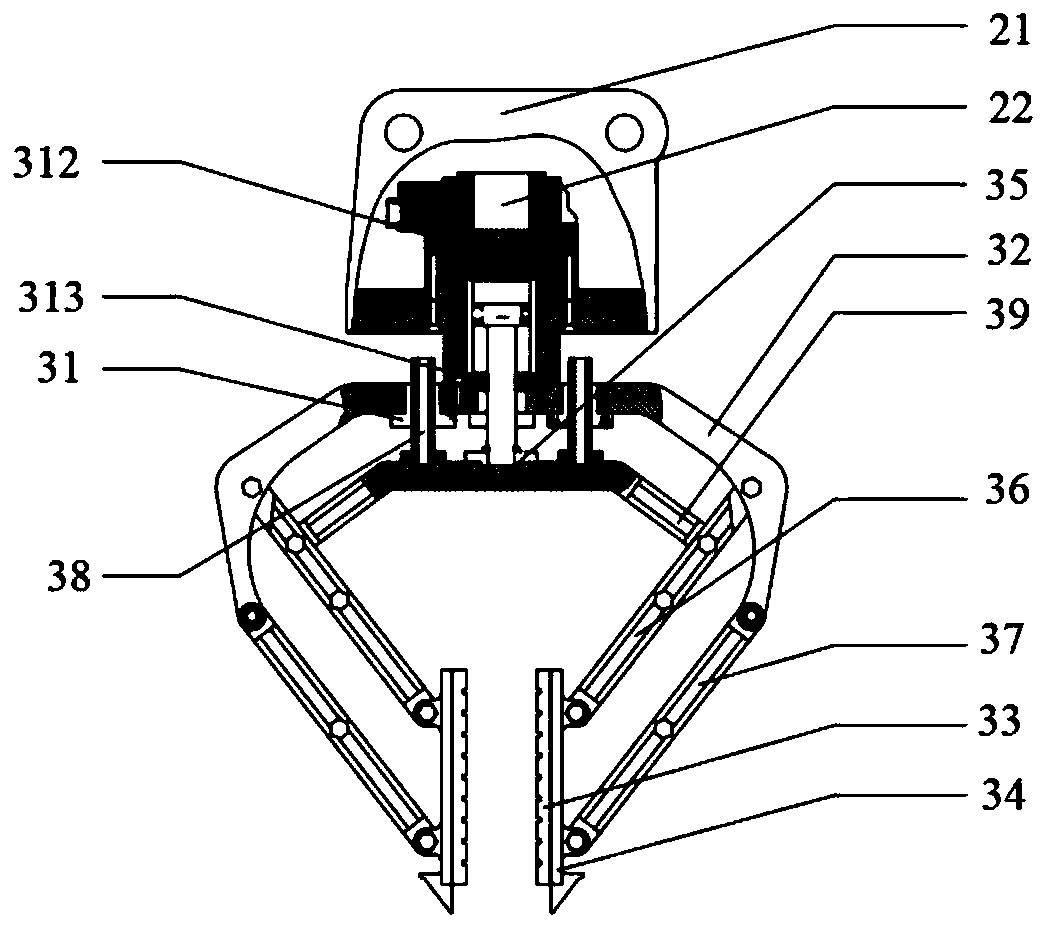

[0021] The above-mentioned automatic curb laying machine based on the excavator platform, during its work, the excavator platform 1 moves to the vicinity of the curb stone stacking place, and at this time the curb stone stacking place and the placement place are located at the curb stone Within the working radius of the automatic laying machine, the chassis slewing device 12 realizes the adjustment of the vehicle angle, and the boom 15 and the small arm 17 of the excavator platform 1 are directed towards the curb, and the boom cylinder 16 and the small boom cylinder 18. Stretching is realized under the cooperation of the bucket cylinder 19, the jaw rotation fine-tuning module 2 adjusts the angle of the jaw clamping module 3, and the piston rod of the telescopic cylinder 312 pushes the push plate 35 downward to make the road The edge stone is located within the clamping range of the splint 34. At this time, the piston rod of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com