A high-efficiency mixing and alternating dual-hole segmental grouting method

A segmented grouting and alternating technology, which is applied in earth-moving drilling, vertical well equipment, wellbore lining, etc., can solve the problems of inhomogeneous slurry diffusion range, poor grouting effect and low grouting efficiency, and achieve uniform slurry diffusion. Scope, fast grouting efficiency, good grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

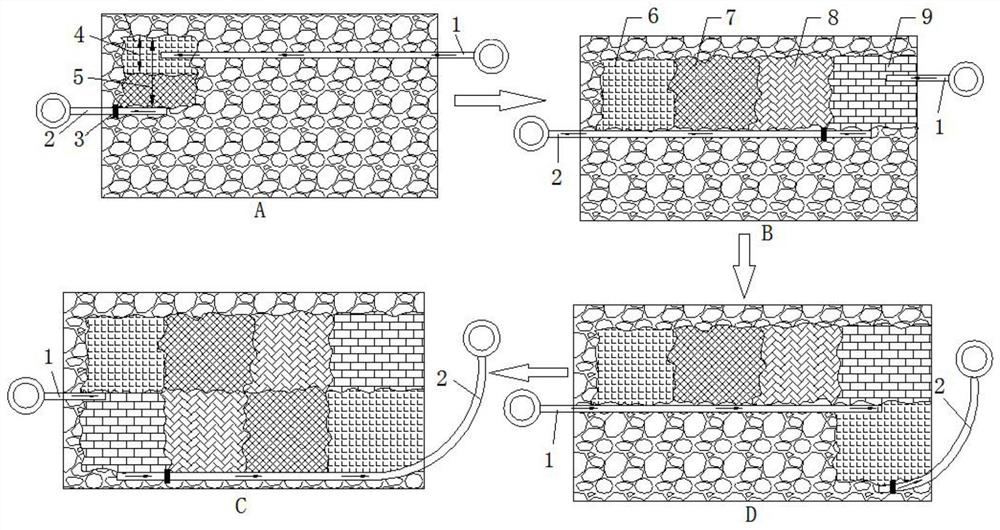

[0033] A high-efficiency mixed alternate double-hole segmented grouting method, comprising the following steps:

[0034] I. First, set the drilling angle, length, position and quantity according to the pre-reinforcement range. According to the design requirements, align the hole positions, and drill holes at both ends of the pre-reinforcement range;

[0035] II. Divide the grouting length of the borehole into several sections according to the geological conditions at the site, and control the retreat distance of each cycle at 2 to 3 meters;

[0036] III. Use a drill bit to open a grouting hole at one end of the pre-reinforcement range. After reaching the drilling depth, withdraw the drilling tool, install a pre-processed No. 1 orifice pipe with a flange in the drill hole, and use quick-setting cement Seal the gap between the No. 1 orifice pipe and the surrounding formation; then replace the drill bit with a diameter smaller than the No. 1 orifice pipe, drill through the No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com