Boiler explosion ash blowing technology injecting inert gas for flame retarding

A boiler explosion, inert gas technology, applied in the field of venturi, can solve the problems of reducing the service life, impact and damage of the equipment on the gas supply pipeline and the gas supply pipeline, so as to reduce the impact, improve the safety and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

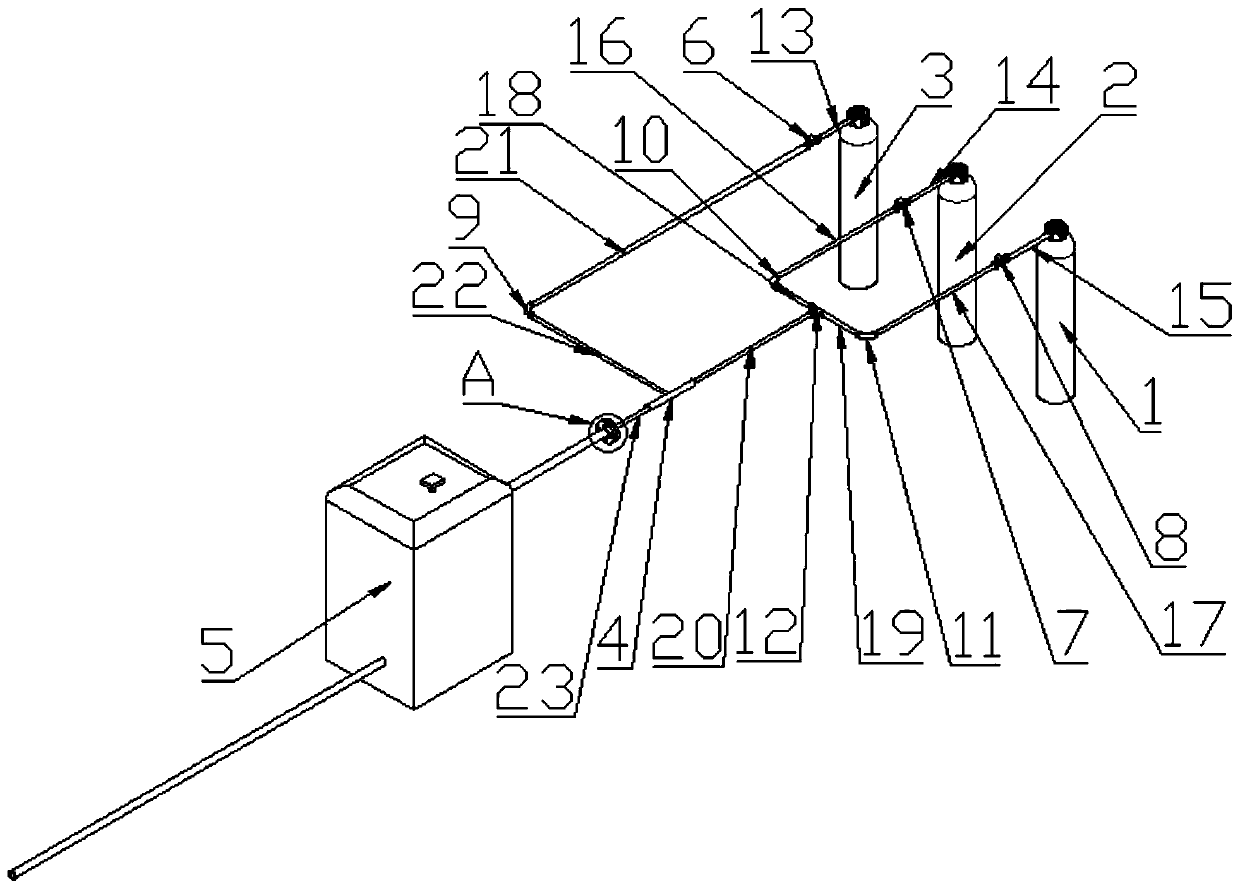

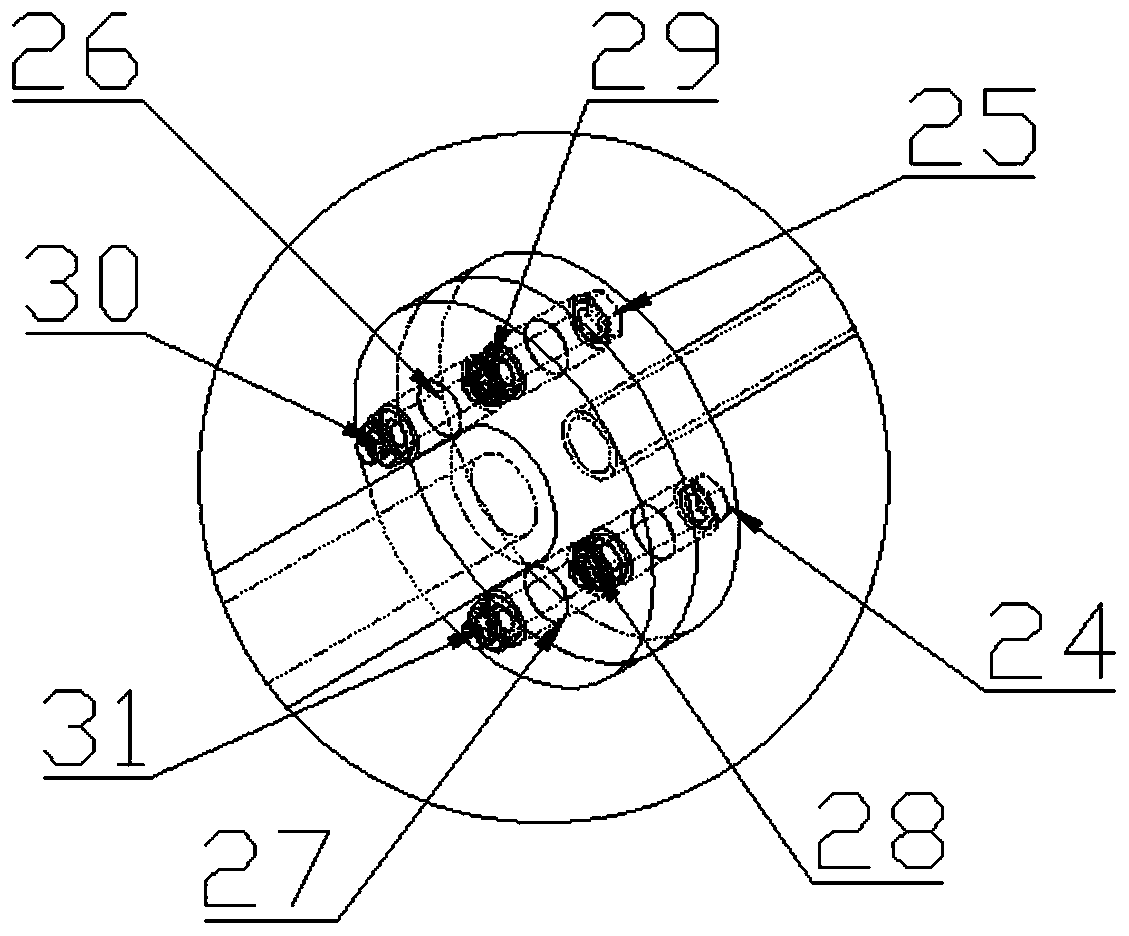

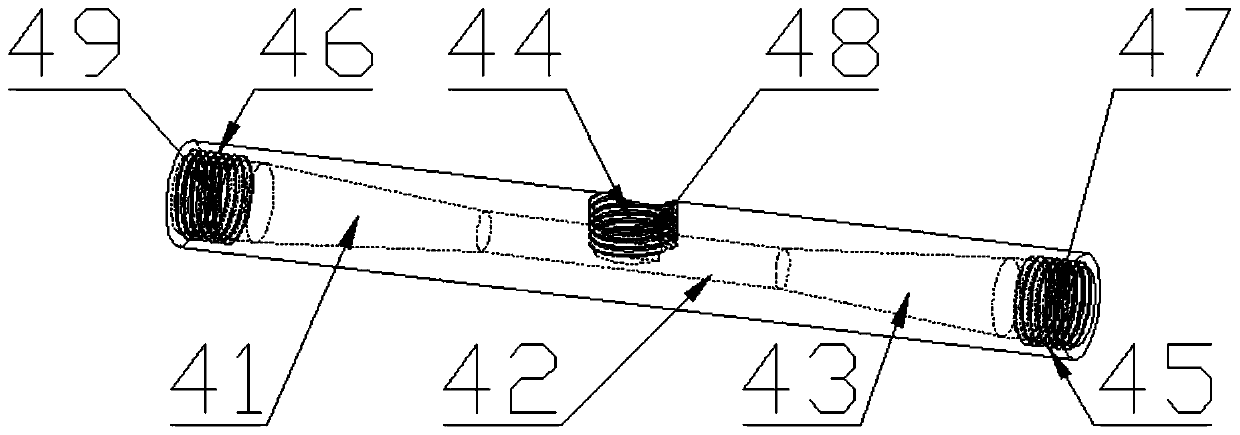

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0032] The present invention is a boiler explosion soot blowing technology for injecting inert gas flame retardant, mainly including oxygen gas cylinder a1, acetylene gas cylinder b2, nitrogen gas cylinder c3, Venturi ejector 4, combustion and explosion device 5, electromagnetic valve a6 , solenoid valve b7, solenoid valve c8, elbow a9, elbow b10, elbow c11, tee joint 12, circular straight pipe a13, circular straight pipe b14, circular straight pipe c15, circular straight pipe d16, Round straight pipe e17, round straight pipe f18, round straight pipe g19, round straight pipe h20, round straight pipe i21, round straight pipe j22, round connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com