Power equipment infrared thermal imaging monitoring system based on artificial intelligence

A technology for infrared thermal imaging and power equipment, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc. The effect of high monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

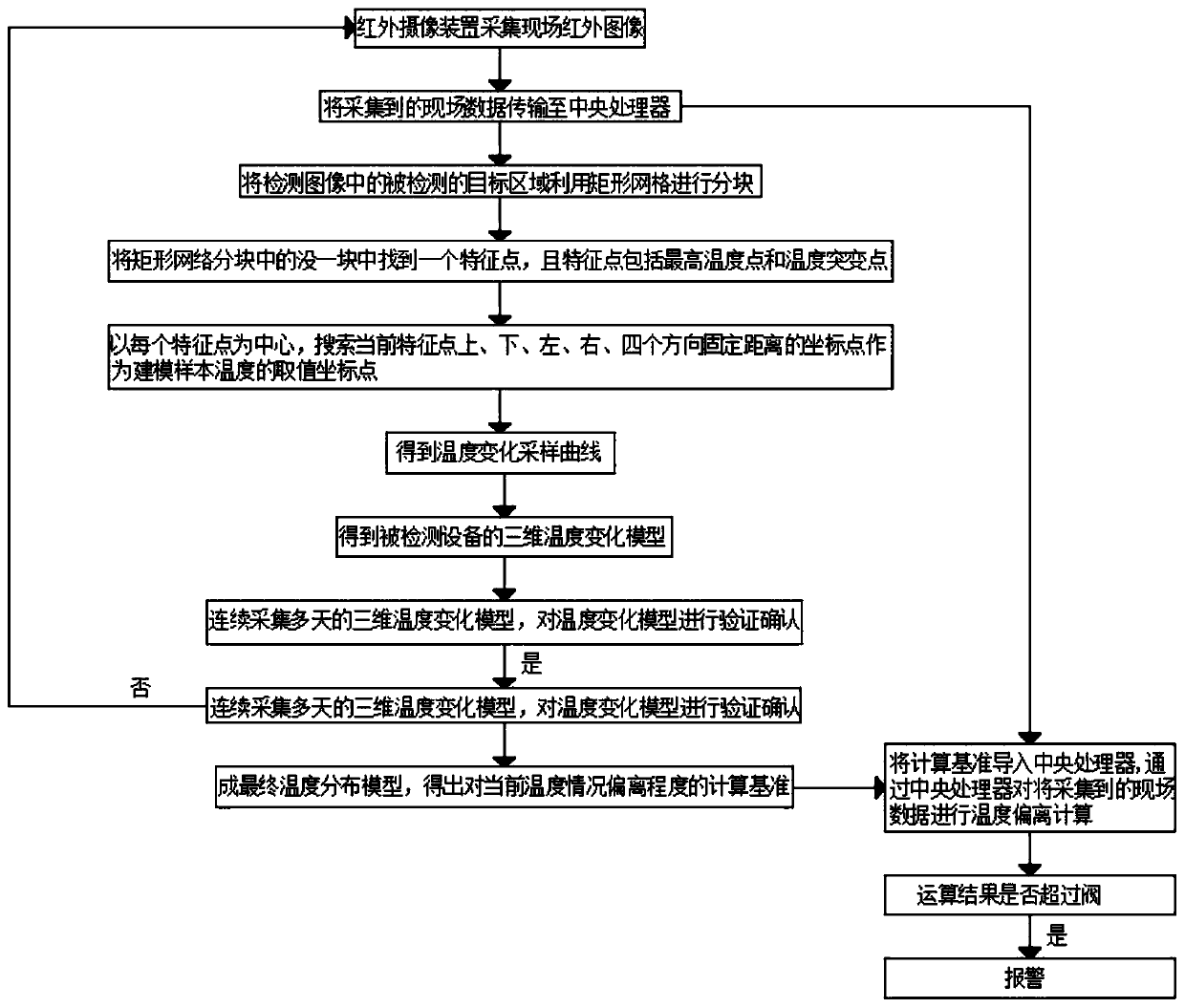

[0031] Example 1, please refer to figure 1 , the present invention provides a technical solution: an artificial intelligence-based infrared thermal imaging monitoring system for power equipment, comprising, characterized in that, comprising the following steps:

[0032] S1. The infrared camera device is installed around the fixed power equipment to collect on-site infrared images;

[0033] S2, transmit the collected field data to the central processing unit through the network;

[0034] S3. Using the infrared image data to analyze the temperature distribution analysis, select the temperature distribution feature points and temperature sample points;

[0035] S4. Collect the temperature values of a group of temperature sample points every certain period of time. Within a period of time, each temperature sample point can obtain a temperature change sampling curve;

[0036] S5. Combining the temperature change sampling curves obtained from all temperature sample points, a thr...

Embodiment 2

[0041] Embodiment two, such as figure 1 As shown, in S3, the detected target area in the detection image is divided into blocks using a rectangular grid. In S3, a feature point is found in each block of the rectangular network block, and the feature points include the highest temperature point and Temperature mutation point, in S3, with each feature point as the center, search for coordinate points with fixed distances in the four directions of up, down, left, right, and four directions of the current feature point as the value coordinate points of the modeling sample temperature, which will be monitored by Carry out rectangular grid blocks in the target area, and establish a corresponding coordinate system. When the system monitors and alarms, the staff only needs to search for data according to the alarm information, and use the established coordinate system for fixed-point processing.

Embodiment 3

[0042] Embodiment three, such as figure 1 As shown, the infrared camera device includes an RGB-D camera and an inertial measurement unit sensor. The threshold value is the temperature mutation point or the highest temperature point of the power equipment. The infrared camera device collects real-time data from the power equipment and transmits the collected data in real time. To the central processing unit, through the central processing unit real-time calculation, if the calculation temperature exceeds the threshold, the over-temperature alarm will reduce human error and labor intensity.

[0043] Working principle: When in use, the infrared camera device is used to continuously collect infrared images on the site, and the temperature distribution characteristic points and temperature sample points are selected through temperature distribution analysis, and the corresponding coordinates are established by making rectangular grid blocks in the monitored target area System, base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com