Test piece and method for testing tensile strength of common concrete by utilizing UHPC

A technology for ordinary concrete and concrete specimens, applied in the field of concrete, can solve problems such as high requirements for models and formwork removal, difficulty in measuring stress-strain relationship, stress concentration, etc., to reduce the effect of sudden changes in stress and performance, Strong grip and the effect of reducing local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

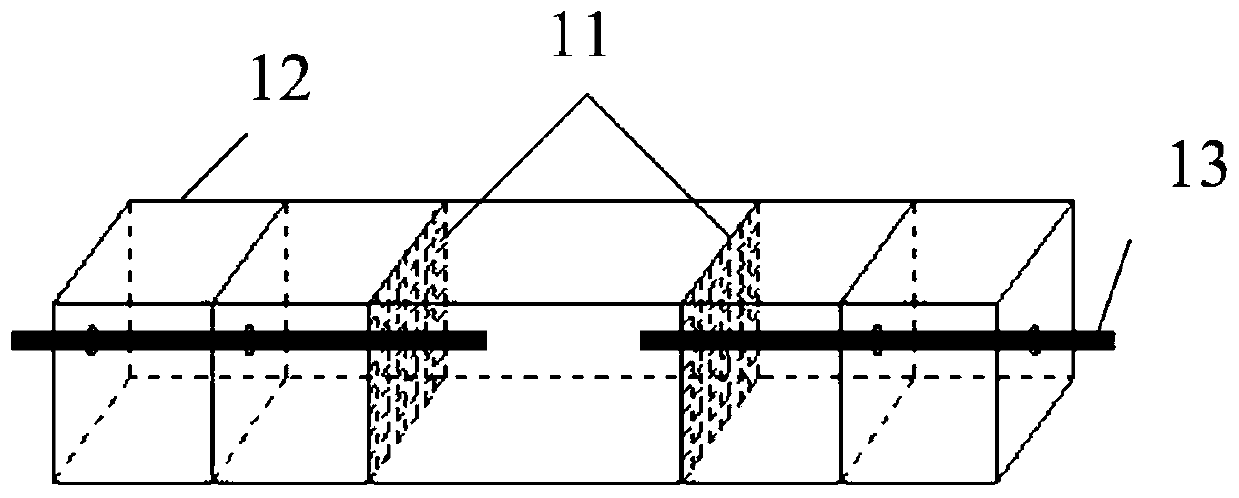

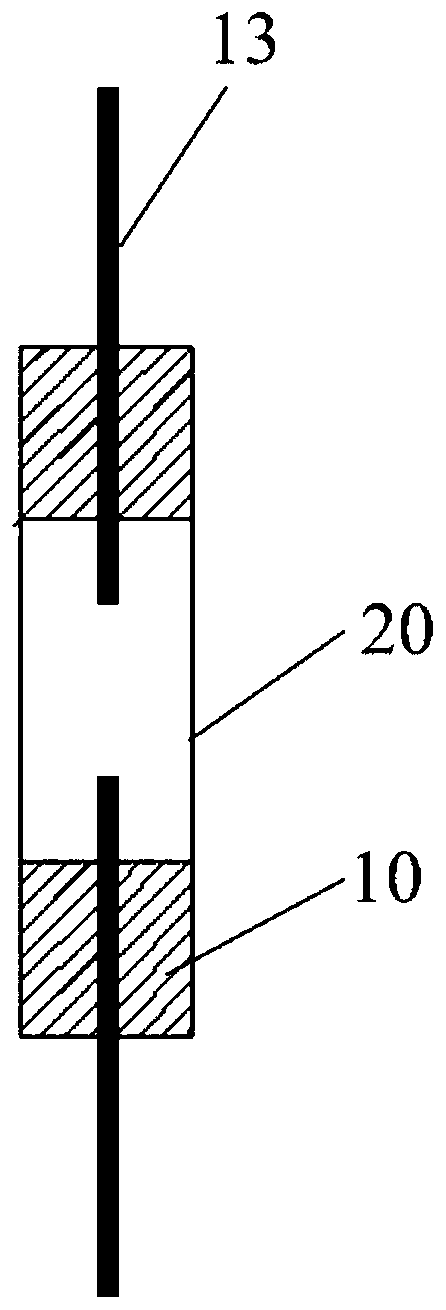

[0029] Combine below figure 1 and figure 2 , describe in detail the test piece and method for testing the tensile strength of ordinary concrete by UHPC of the present invention.

[0030] Please refer to figure 1 and figure 2 ,

[0031] A test piece for testing the tensile strength of ordinary concrete using UHPC, including:

[0032] The cast-in-place UHPC test piece unit 10 and the concrete test piece unit 20 are connected into an integrated structure. The two UHPC test piece units 10 are respectively located on the left and right sides of the concrete test piece unit 20 to be tested; There are steel mesh sheets 11 and end plates 12, the steel mesh sheets 11 are arranged on the side close to the concrete test piece unit 10 to be tested, and the end plate 12 is arranged on the side away from the concrete test piece unit 20 to be tested; The end plates 12 are connected by threaded steel bars 13 .

[0033] Specifically, UHPC is used to test the tensile strength of ordinar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com