Automatic fermentation dryer for preparing bread

An automatic fermentation and dryer technology, applied in dough fermenter, baking, application, etc., can solve the problems of bread deformation, cumbersome process, waste of materials, etc., and achieve the effects of avoiding waste, improving work efficiency, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

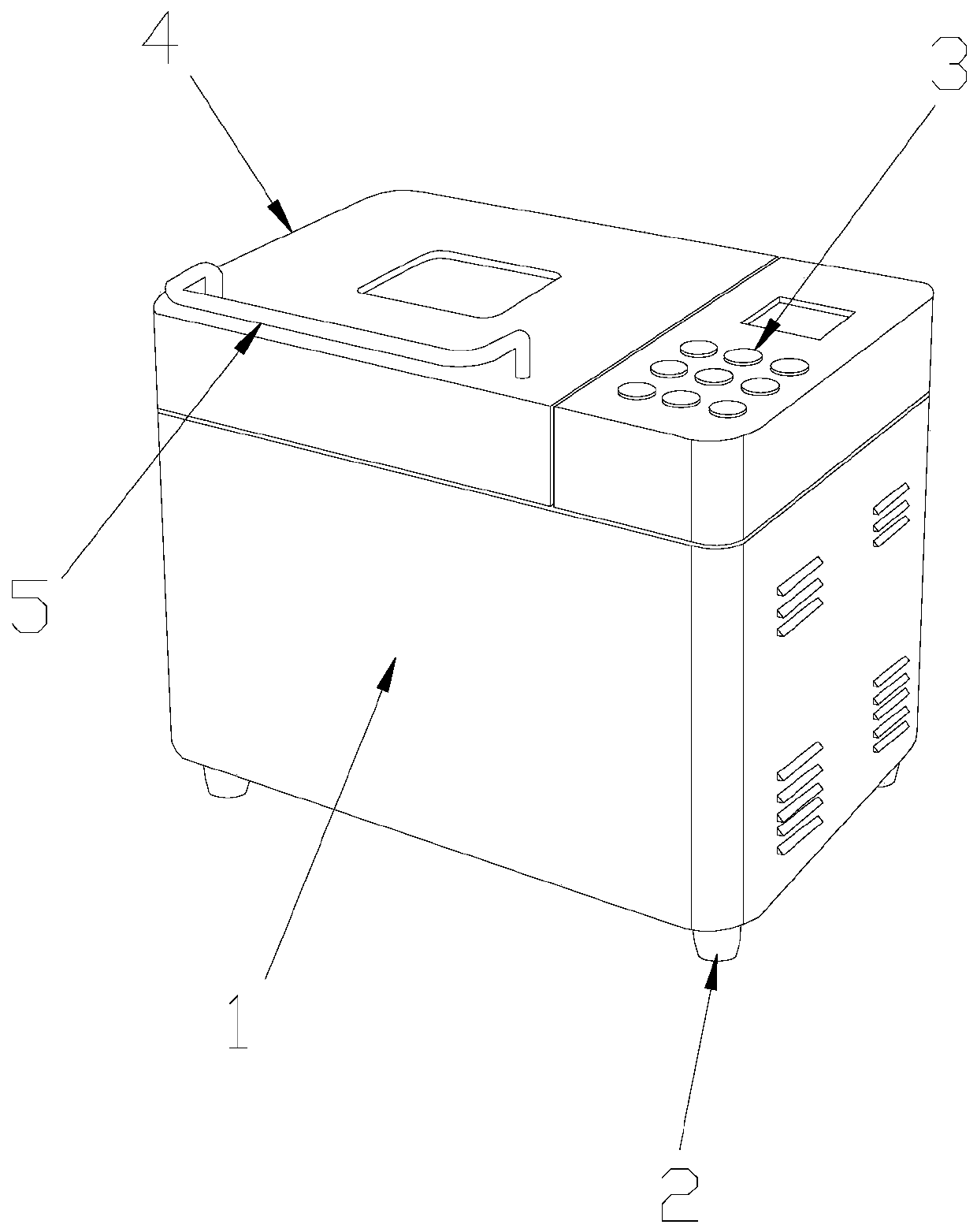

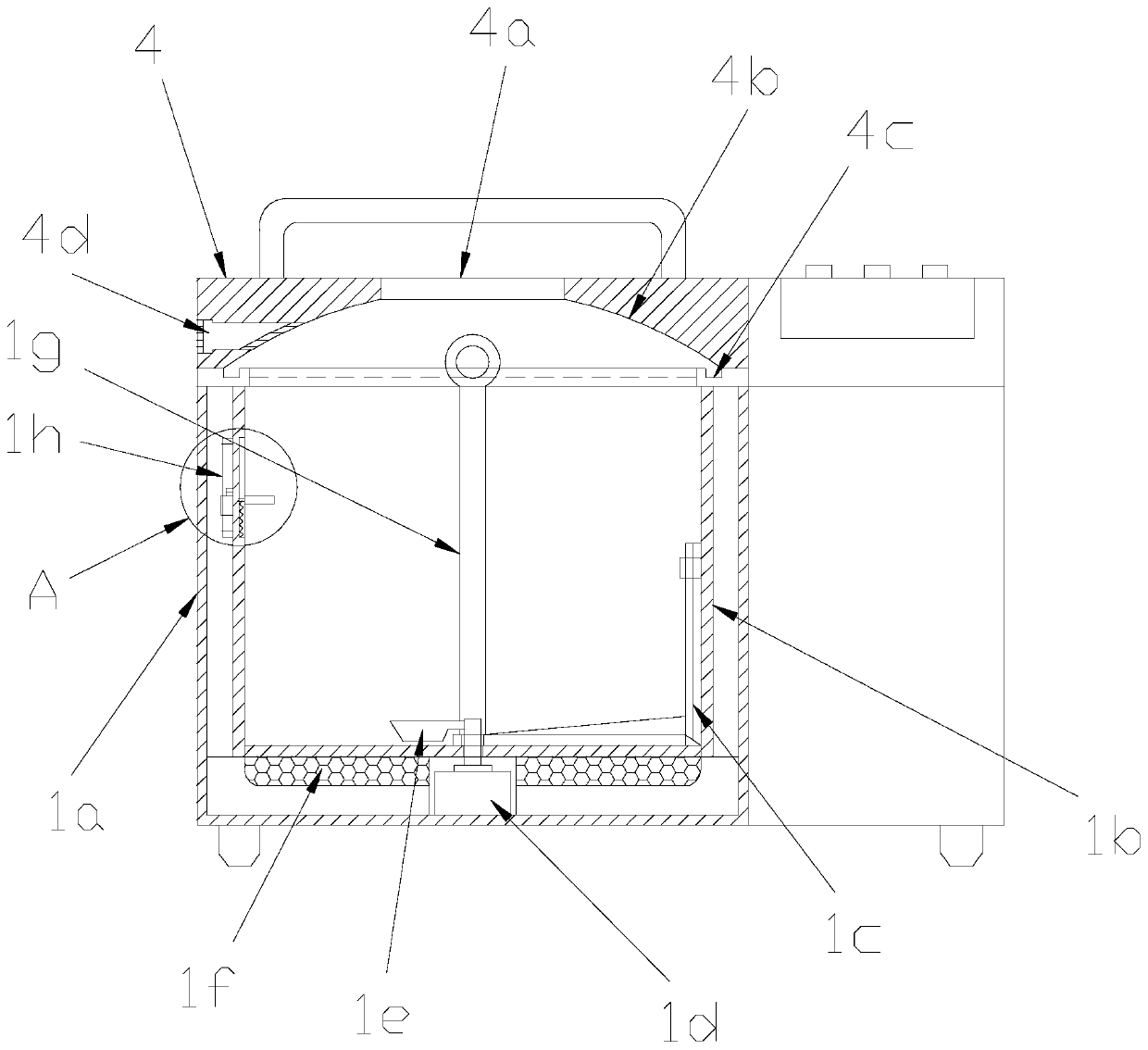

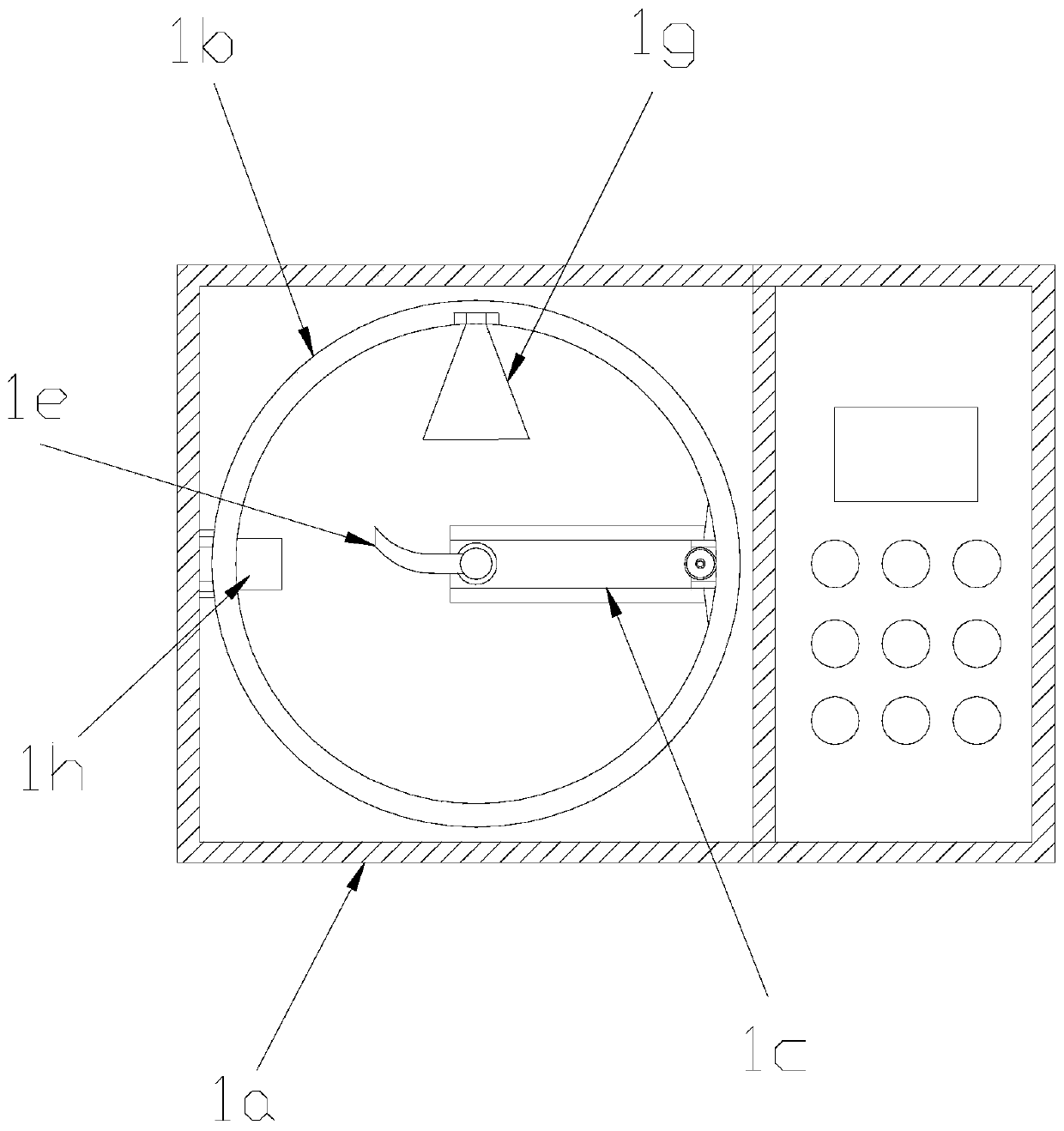

[0027] See Figure 1-Figure 6 , The present invention provides an automatic fermentation dryer for bread making, and its structure includes a bread dryer 1, a supporting foot 2, an electric controller 3, a flip cover 4, a flip cover handle 5, and the bread dryer 1 A support foot 2 is provided under the bottom end, and the bread dryer 1 and the support foot 2 are threadedly connected, an electric controller 3 is installed on the right side of the top of the bread dryer 1, and the bread dryer 1 1 is provided with a flip cover 4 on the left side of the top, the bread dryer 1 and the flip cover 4 are connected by a hinge, the flip cover 4 is provided with a flip cover handle 5 on the surface, the flip cover 4 and the flip cover handle 5 are fixedly connected, The bread dryer 1 is composed of a body 1a, an inner container 1b, a summarizing mechanism 1c, a motor 1d, a stirring shaft 1e, a heating ring 1f, an extracting mechanism 1g, and a fermentation mechanism 1h. The tank 1b, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap