Abrasive production method for manufacturing coated abrasive tool

A production method and technology of coated abrasives, applied in the direction of solid separation, etc., can solve problems such as the influence of coated abrasives production, and achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

[0018] The core of the application is to provide a method for producing abrasives for making coated abrasives, which can solve the problem of how to improve the cleanliness of abrasives used to make coated abrasives in the prior art, and avoid the production of coated abrasives. impact issues.

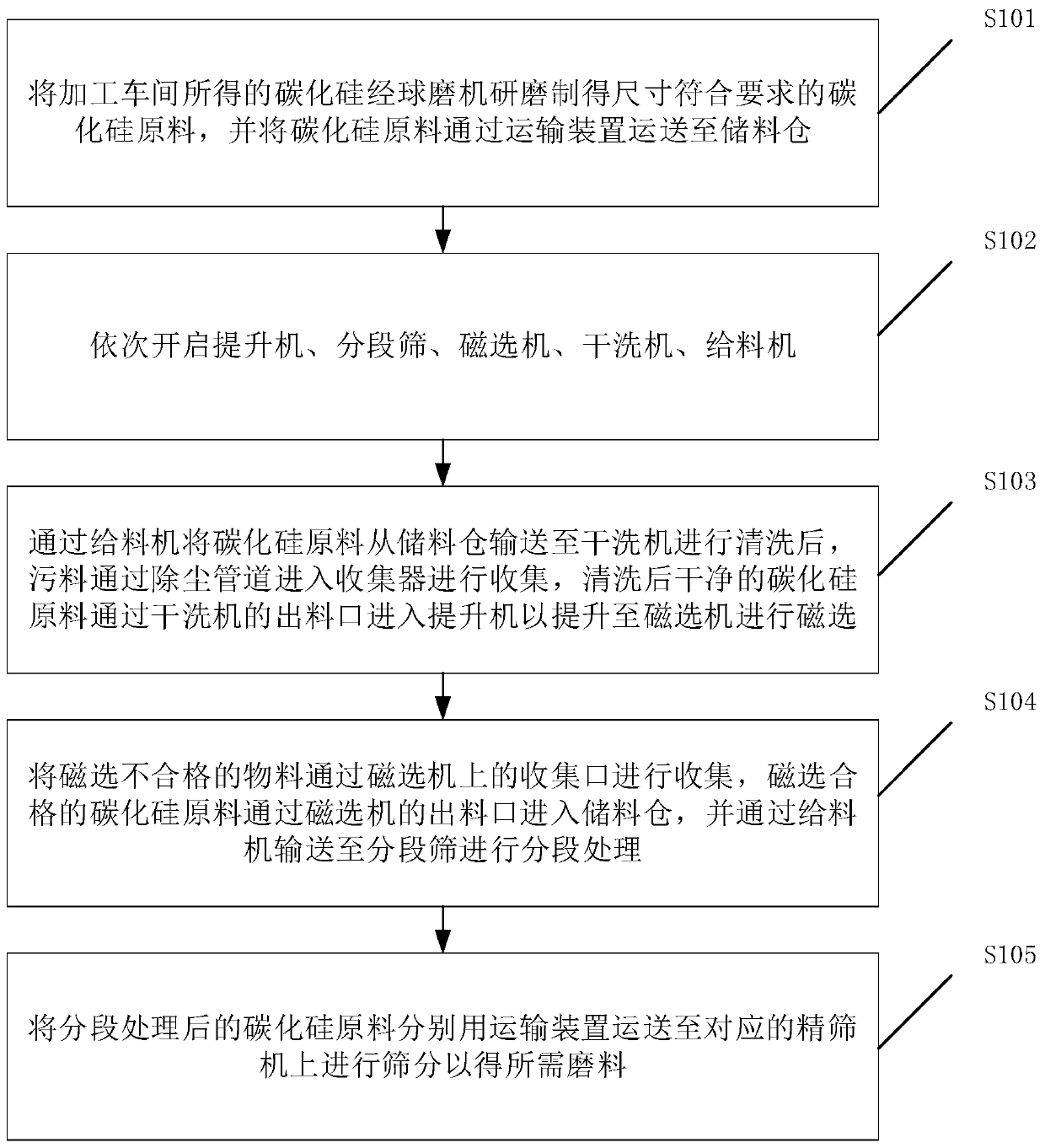

[0019] figure 1 A flow chart of an abrasive production method for making coated abrasives provided by the embodiments of the present invention, such as figure 1 As shown, the method includes the following steps:

[0020] S101: Grinding the silicon carbide obtained in the processing workshop through a ball mill to obtain a silicon carbide raw material with a size that meets the requirements, and tran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap