Medicine crushing device for pediatric department

A crushing device and medicine technology, which is applied in the direction of grain processing, etc., can solve the problems of complex drug crushing device mechanism, incomplete drug crushing, and low crushing efficiency, and achieve the effect of improving impact crushing effect, simple structure, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

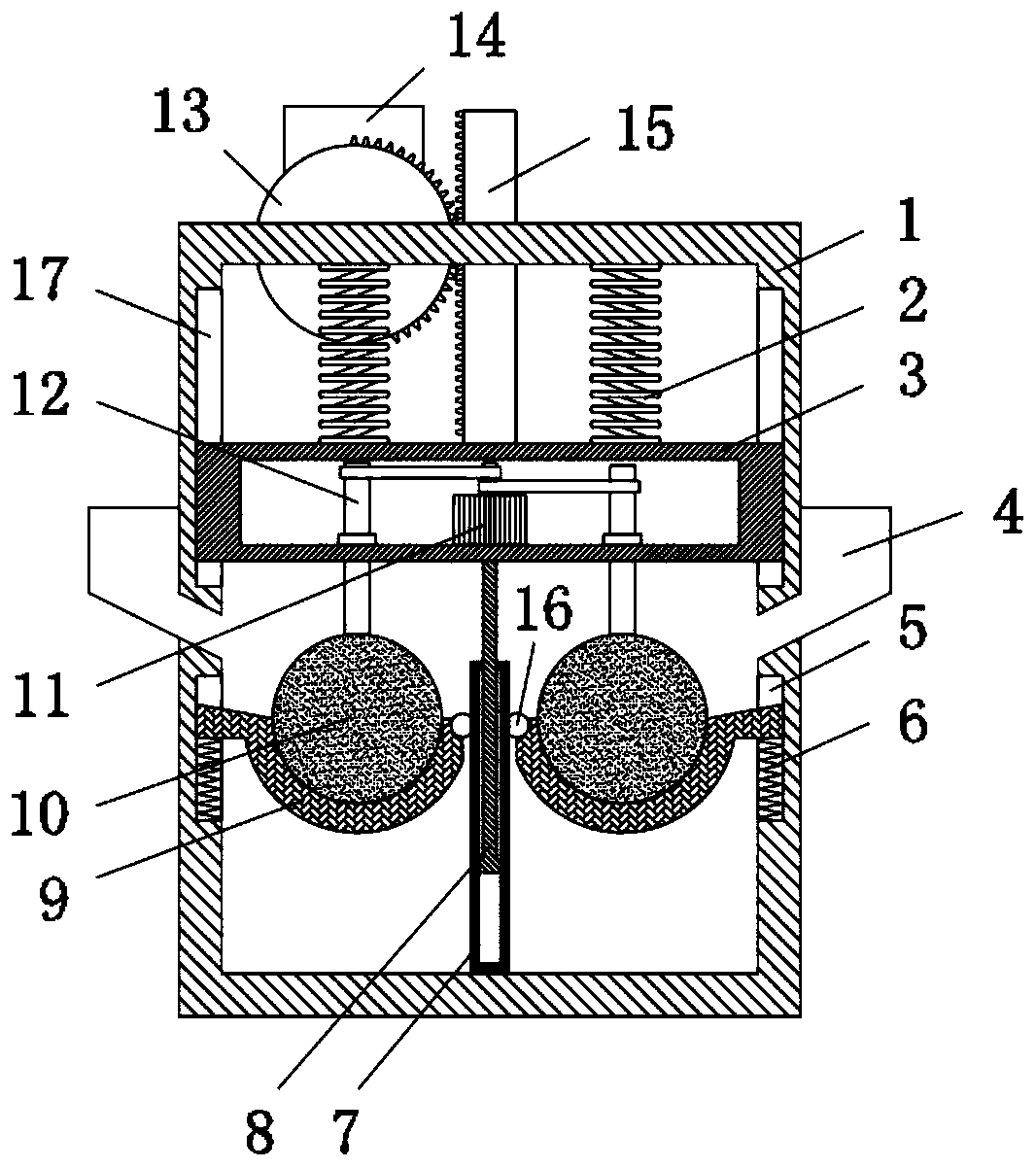

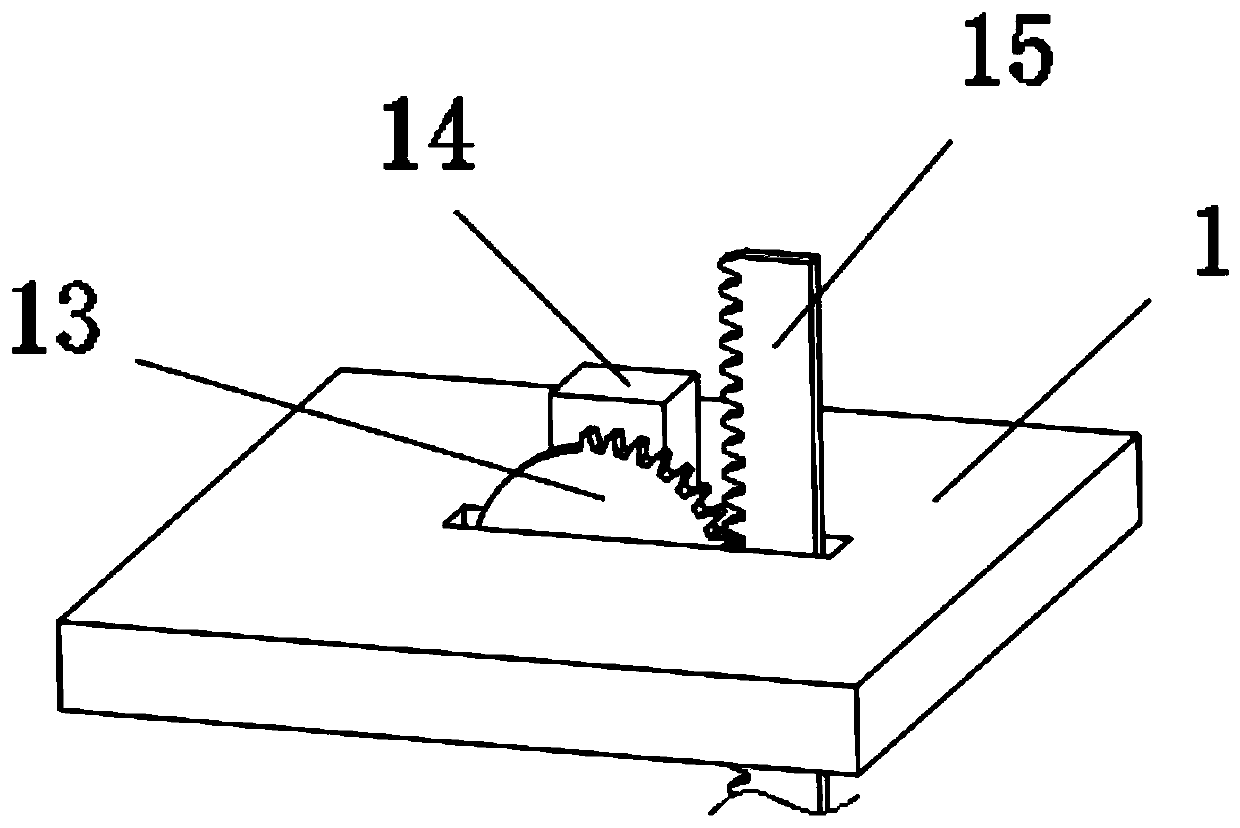

[0017] see Figure 1-2 , a pediatric medicine pulverizing device, comprising a shell 1 and a pulverizing assembly installed inside the shell 1, the shell 1 is provided with a drug inlet 4, the pulverizing assembly includes a grinding mechanism and a lifting mechanism, and the grinding mechanism includes a lifting block 3 and the crushing ball 10, a second chute 17 is opened above the inner wall of the casing 1, the lifting block 3 is slidably clamped in the second chute 17, the lifting block 3 is provided with a cavity, and the lifting block 3 is A first drive motor 11 is fixedly installed in the cavity, a rotating shaft 12 is rotatably arranged on the lifting block 3, and a grinding ball 10 is fixedly installed at the bottom of the rotating shaft 12. The output end of the first drive motor 11 passes between the belt and the rotating shaft 12. Drive connection, a first chute 5 is opened under the inner wall of the outer shell 1, the first chute 5 is slidably clamped with a sie...

Embodiment 2

[0022] This embodiment is a further improvement on the basis of Embodiment 1. Compared with Embodiment 1, the main difference is: the bottom of the lifting block 3 is fixedly installed with a sliding plate 8, and the bottom inner wall of the casing 1 is fixedly installed with a partition The plate 7, the sliding plate 8 is slidably clamped in the partition plate 7, the number of the medicine inlet 4, the rotating shaft 12, the grinding ball 10 and the sieve plate 9 are all set to two, and the installation positions are located on both sides of the partition plate 7, The two sides of the bottom of the casing 1 are separated by arranging the partition plate 7 and sliding and clamping the sliding plate 8 in the partition plate 7, so that two different medicines can be put into the casing 1 through the two medicine inlets 4. On the sieve plate 9, respectively crushing is carried out, which improves the crushing efficiency of the medicine.

[0023] In order to ensure that the sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com