Label printing device capable of automatically tensioning and contracting

A label printing and automatic technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of high label tape positioning accuracy, inability to monitor and adjust paper tape slack in real time, label paper printing misalignment, etc. It achieves the effects of efficient and convenient adjustment, ensuring moderate tension and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

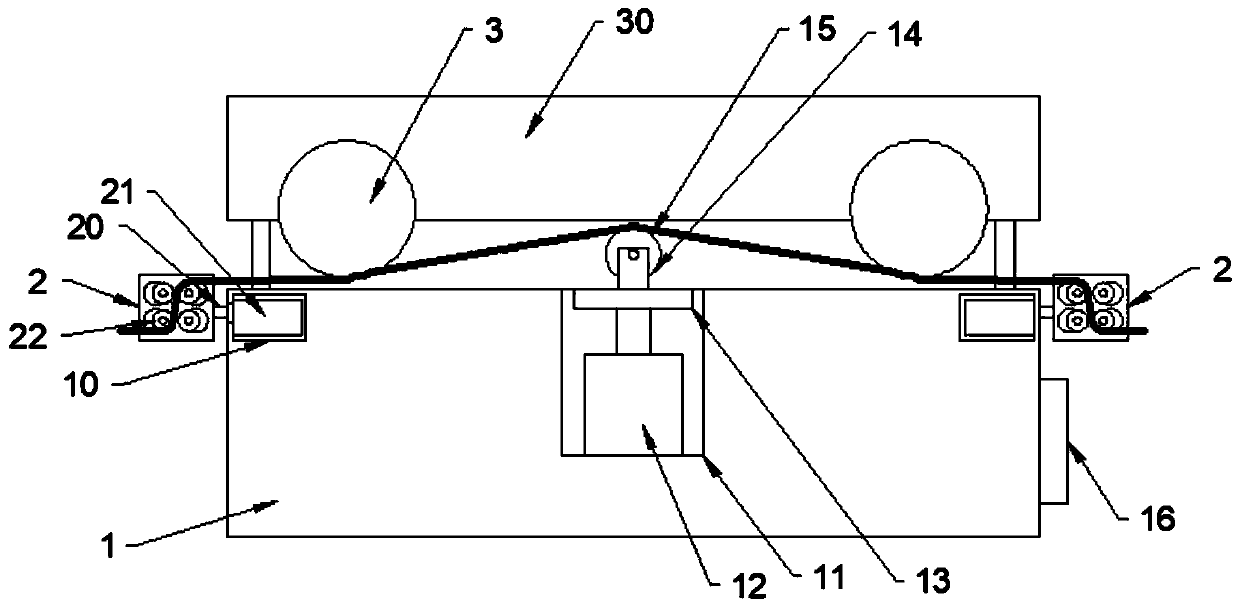

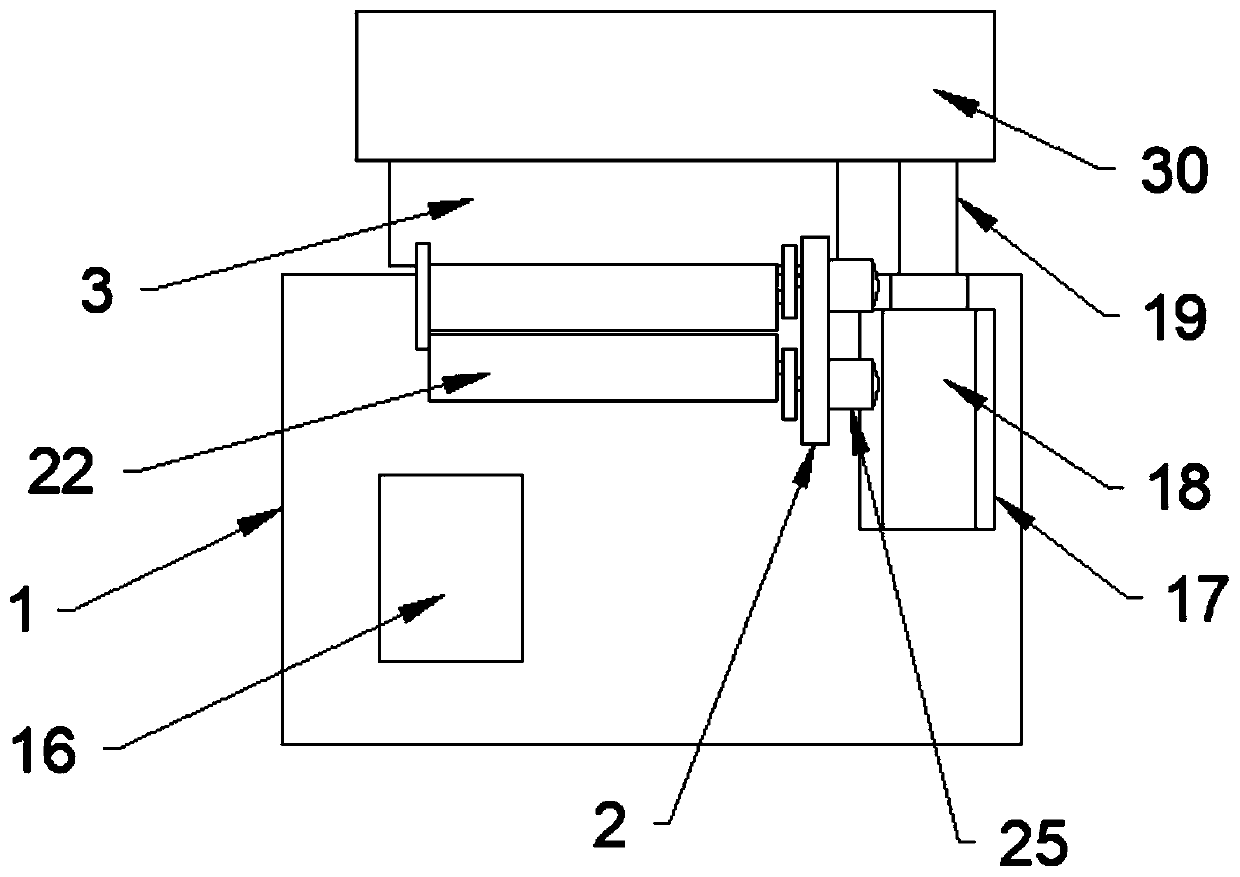

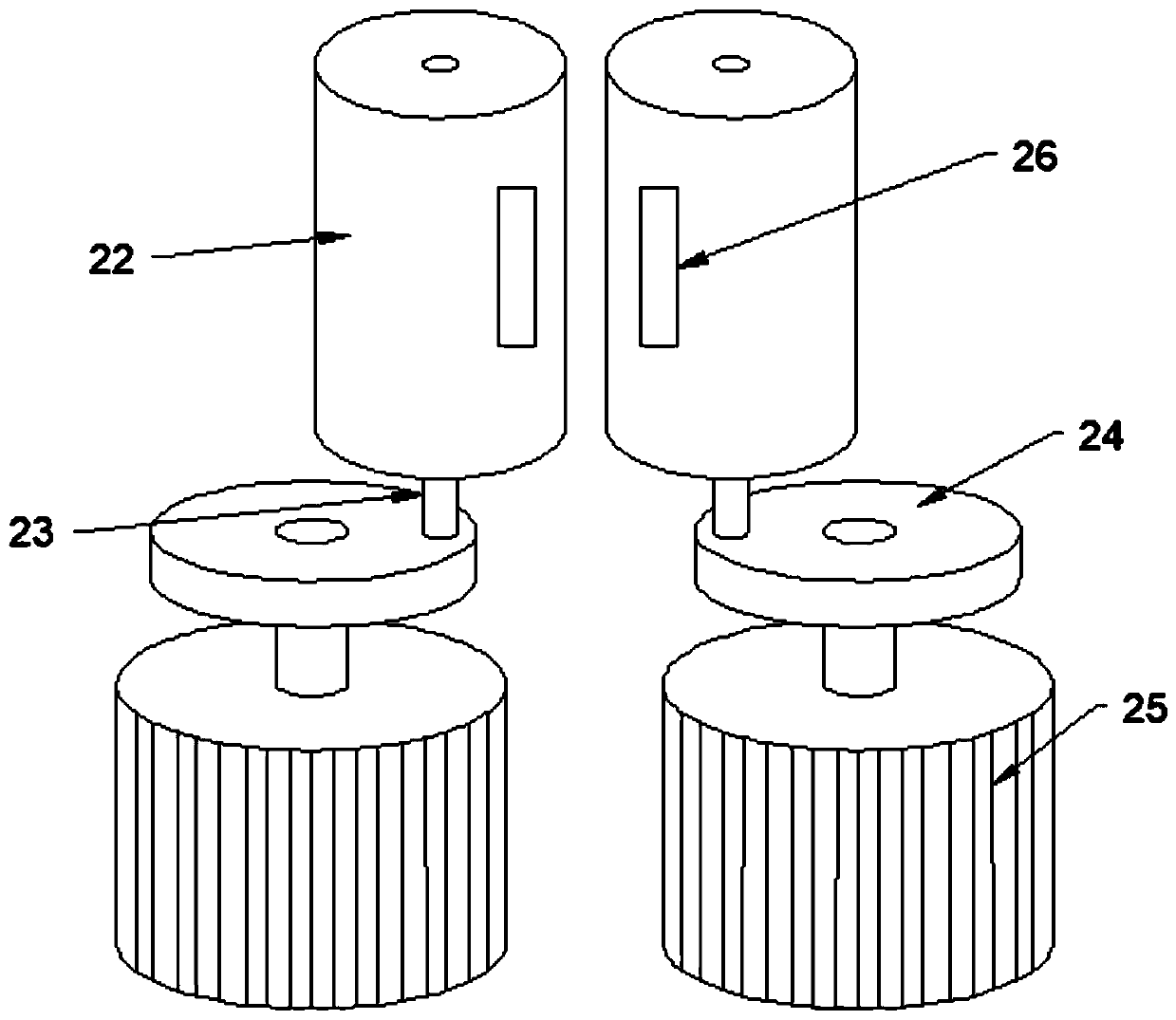

[0025] see Figure 1~4 , in an embodiment of the present invention, an automatic tensioning and shrinking label printing equipment includes a printing table 1, a guide roller 22 and a printing cylinder 3, and the main two side walls of the printing table 1 are respectively provided with a guide roller support plate 2 A plurality of guide rollers 22 for threading label paper tapes are rotated and fixed on the guide roller support plate 2, and multiple rows of printing cylinders 3 for label paper printing are arranged above the top surface of the printing table 1, so The printing cylinder 3 is rotatably installed on the bottom surface of the printing machine box 30, the printing machine box 30 is fixed directly above the printing table 1 through a lifting mechanism, and the guide roller support plate 2 is installed on the left and right side walls of the printing table 1 through a stretching mechanism , the front panel of the guide roller support plate 2 is provided with two opp...

Embodiment 2

[0033] see Figure 5-6 , the difference between this embodiment and embodiment 1 is:

[0034] The bottom surface of the printing machine box 30 is provided with a dedusting mechanism for dedusting the surface of the label tape and a drying and blowing device for drying the printed label tape.

[0035] The dust removal mechanism includes a dust removal tuyere 31 and a dust removal blower 32. The dust removal tuyere 31 is set longitudinally on the left side of the bottom surface of the printing cylinder 3. The dust removal blower 32 is fixed inside the printing machine box 30. The dust removal tuyere 31 is along the The label tape conveying direction is set obliquely. Here, the wind blown by the dust removal blower 32 is mainly blown in the opposite direction of the label paper tape printing, so as to prevent dust from falling into the printing area.

[0036] Described drying and blowing device comprises drying tuyeres 33, printing machine case 30 and drying blower 37, and desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com