Method for activating waste slag from stone washing in quarry, cement-based activated waste slag concrete, and preparation method of the concrete

A cement-based, concrete technology, which is applied in the preparation of the concrete, the activation of the waste slag made from stone washing in the quarry, and the field of cement-based activated waste slag concrete, which can solve the problems of increased water demand, decreased strength, and low activity of waste slag in concrete. , to achieve the effect of maximizing resource utilization, increasing compressive strength, and solving disposal difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

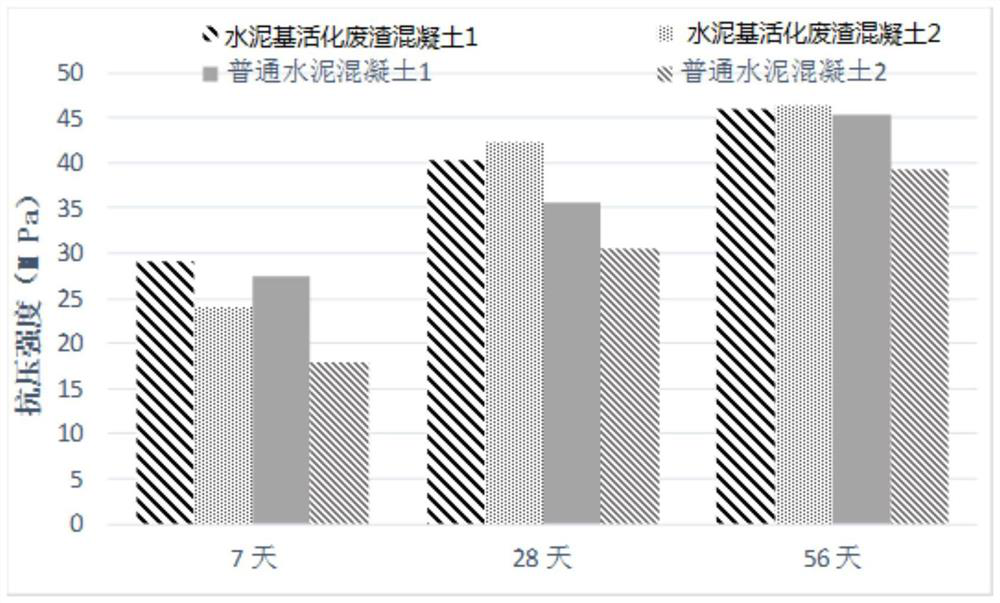

Examples

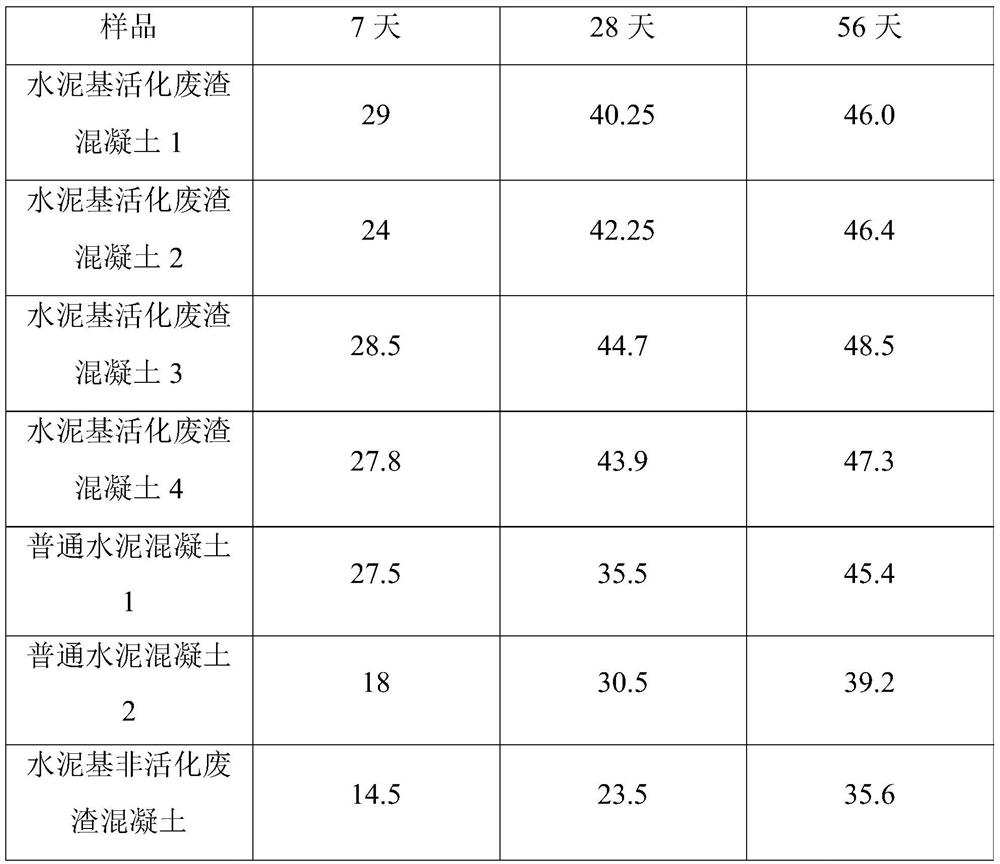

Embodiment 1

[0025] After the waste residue is dried in an oven at 100°C, it is dry-screened through a 32-micron screen, the undersize is stored and retained, and the oversize is further crushed and powdered for sieving; all sieved waste undersize is collected and placed in a Calcined at 900°C for 30 minutes in a high-temperature furnace, and after cooling to room temperature, grind the ashes in a ball mill;

[0026] Collect the activated waste slag after grinding to prepare cement-based activated waste slag concrete, using ordinary 42.5 cement. 192 parts of raw material, 128 parts of fine aggregate, and 1 part of high-efficiency polycarboxylate superplasticizer.

[0027] Put cement, activated waste slag, sand and aggregate into the mixer for mixing by weight. The mixing time for dry powder is 1.5min. After mixing evenly, add water and water reducer for 3min. After mixing evenly, transfer The mold was subjected to vibration molding, and the sample was cured in a standard curing box (20° C...

Embodiment 2

[0029] After the waste residue is dried in an oven at 80°C, it is dry-screened through a 20-micron sieve, the undersize is stored and retained, and the oversize is further crushed and powdered for sieving; all sieved waste undersize is collected and placed in a Calcined at 700°C for 90 minutes in a high-temperature furnace, and after cooling to room temperature, grind the ashes in a ball mill;

[0030] Collect the activated waste slag after grinding to prepare cement-based activated waste slag concrete, using ordinary 42.5 cement, and the components are calculated by weight: 75 parts of cement, 75 parts of activated waste slag, 40 parts of water, 185 parts of sand, coarse bone 142.5 parts of material, 142.5 parts of fine aggregate.

[0031] Add cement, activated waste slag, sand and aggregate to the mixer for mixing by weight. The mixing time for dry powder is 2 minutes. After mixing evenly, add water for mixing. The mixing time is 4 minutes. After mixing evenly, transfer to t...

Embodiment 3

[0033] After the waste residue is dried in an oven at 110°C, it is dry-sieved through a 75-micron sieve, the undersize is stored and retained, and the oversize is further crushed and powdered for sieving; all sieved waste undersize is collected and placed in a Calcined in a high-temperature furnace at 800°C for 60 minutes, and after cooling to room temperature, grind the ashes in a ball mill;

[0034] Collect the activated waste slag after grinding to prepare cement-based activated waste slag concrete, using ordinary 42.5 cement. 180 parts of raw material, 150 parts of fine aggregate, and 2 parts of high-efficiency polycarboxylate superplasticizer.

[0035] Put cement, activated waste slag, sand and aggregate into the mixer by weight and mix them. The mixing time for dry powder is 1min. After mixing evenly, add water and water reducer for 2min. After mixing evenly, transfer to The mold was subjected to vibration molding, and the sample was cured in a standard curing box (20°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com