Method for recycling vanadium-chromium-titanium waste salt in chlor-alkali

A vanadium-chromium-titanium and chlor-alkali technology, which is applied in the purification of alkali metal chlorides and alkali metal halides, can solve problems such as the difficulty of solid waste salt disposal, and achieve the effect of solving the difficulty of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

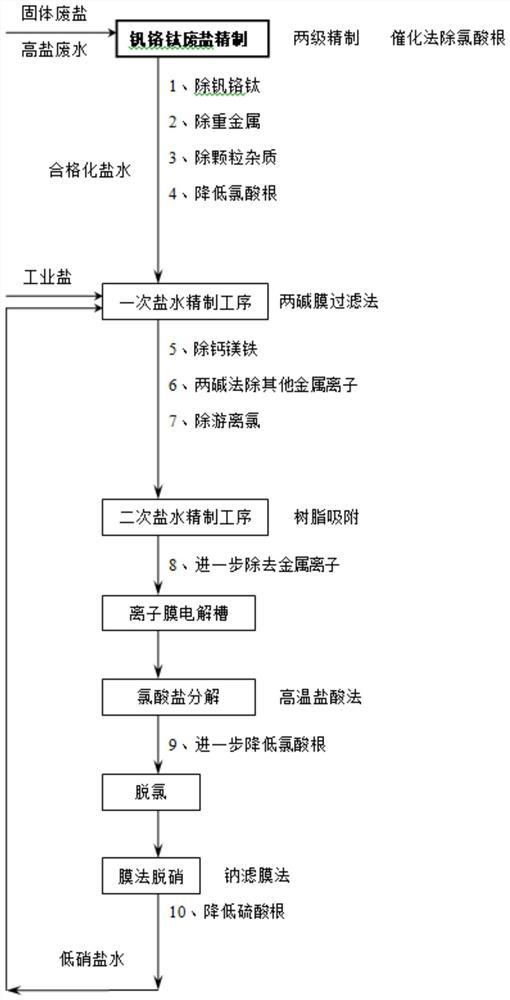

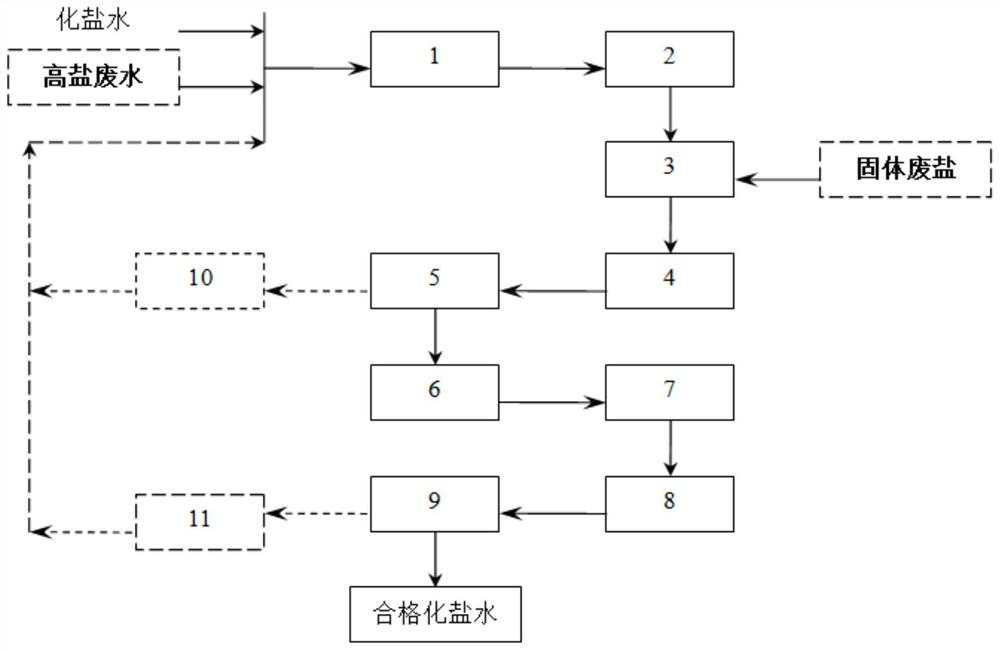

[0042] In one embodiment of the present invention, as figure 1 As shown, there is provided a kind of vanadium-chromium-titanium waste salt recycling method for chlor-alkali, comprising the following steps:

[0043] (1) Pass solid waste salt and high-salt waste water into the vanadium-chromium-titanium waste salt refining system, remove vanadium-chromium-titanium, heavy metal ions and particulate impurities through two-step refined membrane filtration, and then catalyze decomposition to reduce the chlorate content to obtain qualified brine;

[0044] (2) After dissolving the industrial salt in the qualified brine and low-nitrate brine obtained in step (1), first remove calcium, magnesium, iron and other metal ions that can be precipitated by the two-alkali membrane filtration method (caustic soda and soda ash are used as refining agents) ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com