Cement kiln bypass exhaust ash resource utilization system and method

A technology of bypass ventilation and cement kiln, applied in the field of solid waste recycling, can solve the problems of high hexavalent chromium content, difficult disposal, short process, etc., achieve low cost, increase investment and disposal costs, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

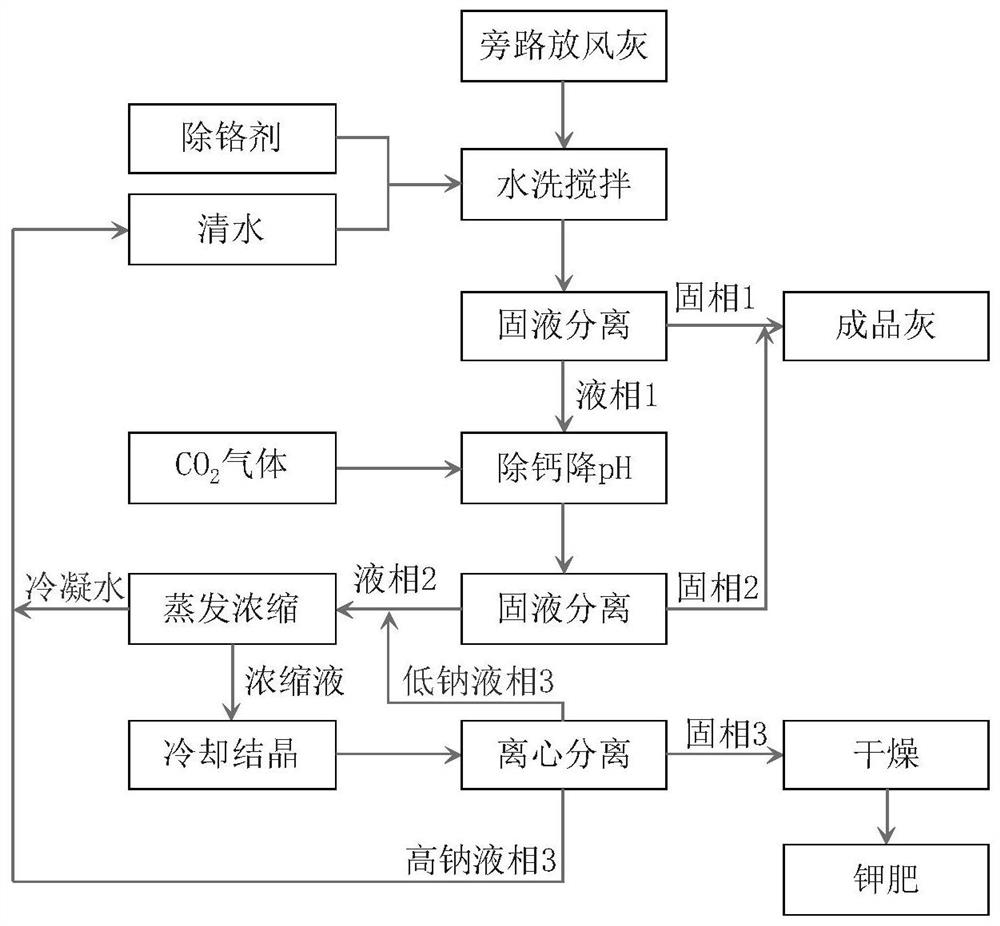

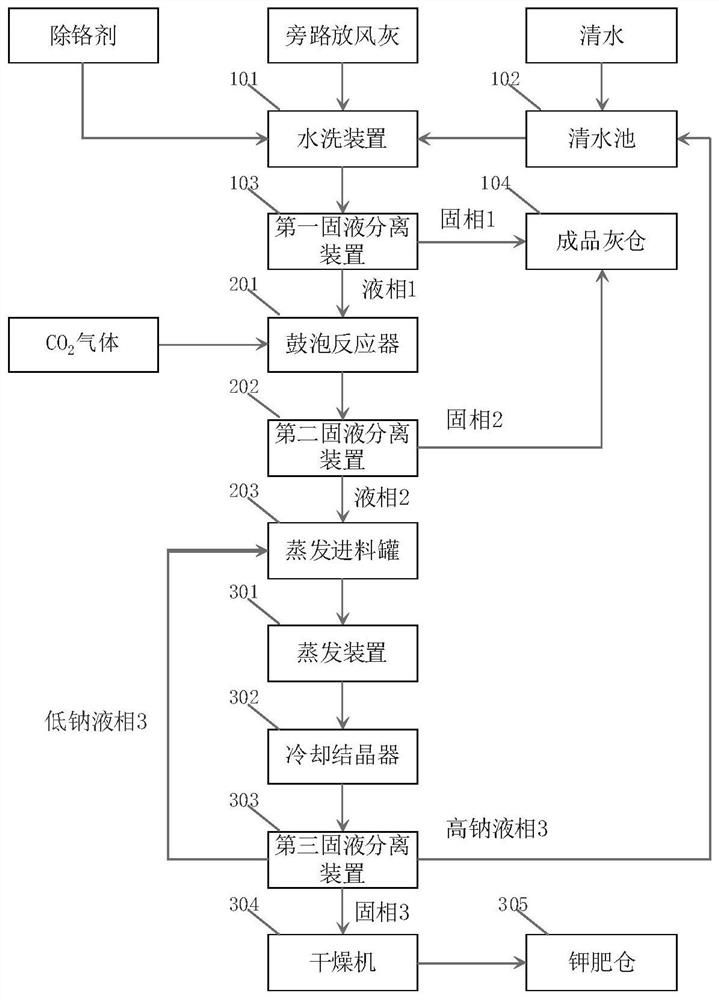

Method used

Image

Examples

Embodiment 1

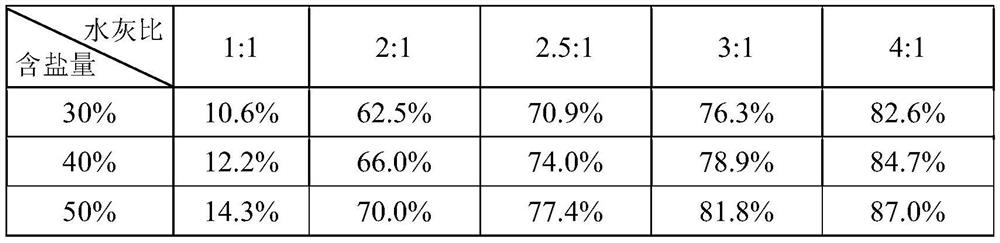

[0076] In this example, the influence of the amount of water added on the washing effect when washing the bypass blown ash with water was first investigated. After collecting the bypass ash samples with different salt content, and then using different water-cement ratios for water washing and solid-liquid separation, the removal rate of soluble salts in the bypass ash is shown in Table 1 below.

[0077] Table 1 Removal rates of soluble salts with different water-cement ratios in bypass blow-off ash with different salt content

[0078]

[0079] Note: The water-cement ratio in Table 1 refers to the weight ratio of water to bypass ash. The salt content refers to the weight percentage content of soluble salts in the bypass bleed ash.

[0080] The results show that the weight ratio of water and bypass ash is preferably 2-4:1, so that the soluble salts in the bypass ash can be fully dissolved into the water, and the bypass ash only needs to be washed once and then solidified. A...

Embodiment 2

[0082] Add water and bypass ash in a weight ratio of 3:1 into the water washing and stirring tank, and add 5‰ of ferrous sulfate by weight of bypass ash at the same time, and stir for 20 minutes to obtain a slurry. Then, the slurry was pumped into a plate and frame filter press, and subjected to high-pressure pressing for solid-liquid separation, and the moisture content of the obtained filter cake was 51.2%. The chemical composition of the bypass ash before and after washing is shown in Table 2 below. After one washing, the dry weight of the finished ash is reduced to about 60% of the weight of the original ash, and about 80% of the alkali chloride and sulfur in the original ash are removed. The finished ash can be directly used in cement production. Considering the disposal cost and practical application, the bypass ash only needs to be washed once, and there is no need to use multiple washings to pursue a higher alkali chloride and sulfur removal rate.

[0083] The pH of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com