A method for harmless disposal and resource utilization of hot-dip galvanizing line alkaline washing sludge

A hot-dip galvanizing and recycling technology, applied in cement production, optics, photography, etc., can solve problems such as waste of resources, reduce processing costs, improve processing effects, and promote environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

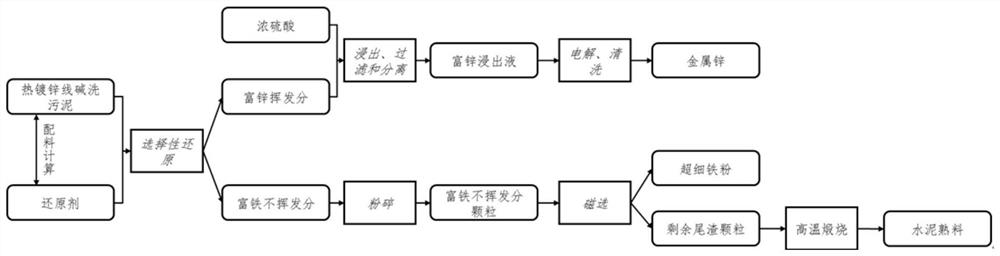

[0043] The main components of the hot-dip galvanizing line alkali-cleaning sludge in this embodiment after being roasted for 2 hours at 400 ° C in a non-oxidizing environment in a muffle furnace are: Fe 2 o 3 The content is 35.58% (the iron in the alkali washing sludge mainly exists in the form of ultrafine iron, which is converted into iron oxide scale after roasting), Al 2 o 3 Content is 19.49%, SiO 2 The CaO content is 17.81%, the CaO content is 12.52%, the ZnO content is 6.95%, and the MgO content is 2.26%. Such as figure 1 As shown, the method for harmless disposal and resource utilization of hot-dip galvanizing line alkaline cleaning sludge in this embodiment includes the following steps:

[0044] Step 1. Selective reduction of alkali washing sludge

[0045] With CO gas, H 2 One or more of the gases and CO 2 The mixed gas of the gas is used as a reducing agent to carry out selective reduction treatment on the alkaline washing sludge of the hot-dip galvanizing line...

Embodiment 2

[0055] The method for harmless disposal and resource utilization of hot-dip galvanizing line alkaline washing sludge in this embodiment includes the following steps:

[0056] Step 1. Selective reduction of alkali washing sludge

[0057] With CO gas, H 2 One or more of the gases and CO 2 The mixed gas of the gas is used as a reducing agent to carry out selective reduction treatment on the alkali washing sludge of the hot-dip galvanizing line. The reduction temperature is 1100 ° C, and the reduction time is 0.5 h. Iron non-volatile matter; the addition M of the reducing agent 还原剂 Calculate according to the following formula:

[0058] m 还原剂 =0.04~0.53M Fe2O3 +0.02~0.34M ZnO -0.11~0.45M 有机物

[0059] Among them: M 还原剂 — mass of reducing agent; M Fe2O3 —Fe in alkali washing sludge of hot-dip galvanizing line 2 o 3 quality; M ZnO — the quality of ZnO in the alkaline washing sludge of the hot-dip galvanizing line; M 有机物 —The quality of organic matter in alkaline washing ...

Embodiment 3

[0067] The method for harmless disposal and resource utilization of hot-dip galvanizing line alkaline washing sludge in this embodiment includes the following steps:

[0068] Step 1. Selective reduction of alkali washing sludge

[0069] With CO gas, H 2 One or more of the gases and CO 2 The mixed gas of the gas is used as a reducing agent to carry out selective reduction treatment on the alkaline washing sludge of the hot-dip galvanizing line. The reduction temperature is 900 ° C, and the reduction time is 1.5 h. Iron non-volatile matter; the addition M of the reducing agent 还原剂 Calculate according to the following formula:

[0070] m 还原剂 =0.04~0.53M Fe2O3 +0.02~0.34M ZnO -0.11~0.45M 有机物

[0071] Among them: M 还原剂 — mass of reducing agent; M Fe2O3 —Fe in alkali washing sludge of hot-dip galvanizing line 2 o 3 quality; M ZnO — the quality of ZnO in the alkaline washing sludge of the hot-dip galvanizing line; M 有机物 —The quality of organic matter in alkaline washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com