A multi-crucible crystal growth furnace with independently controllable stations and control method

A crystal growth furnace, independent control technology, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that the stations can only be controlled by linkage, but cannot be controlled individually, and achieve the effect of avoiding uneven temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

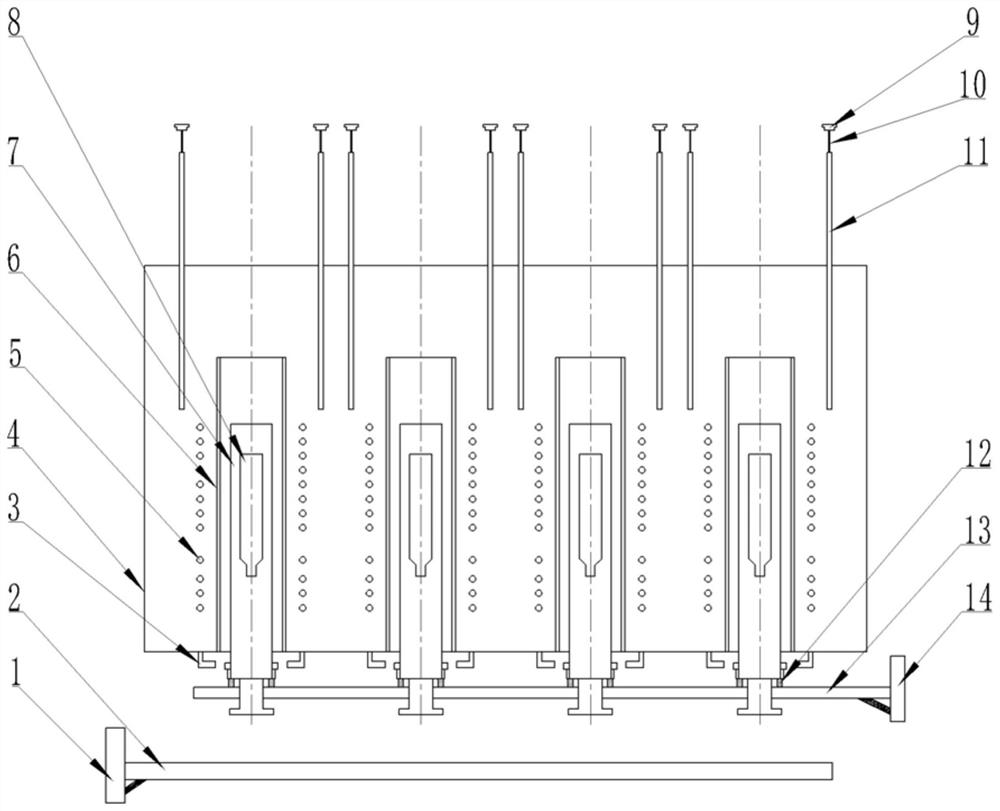

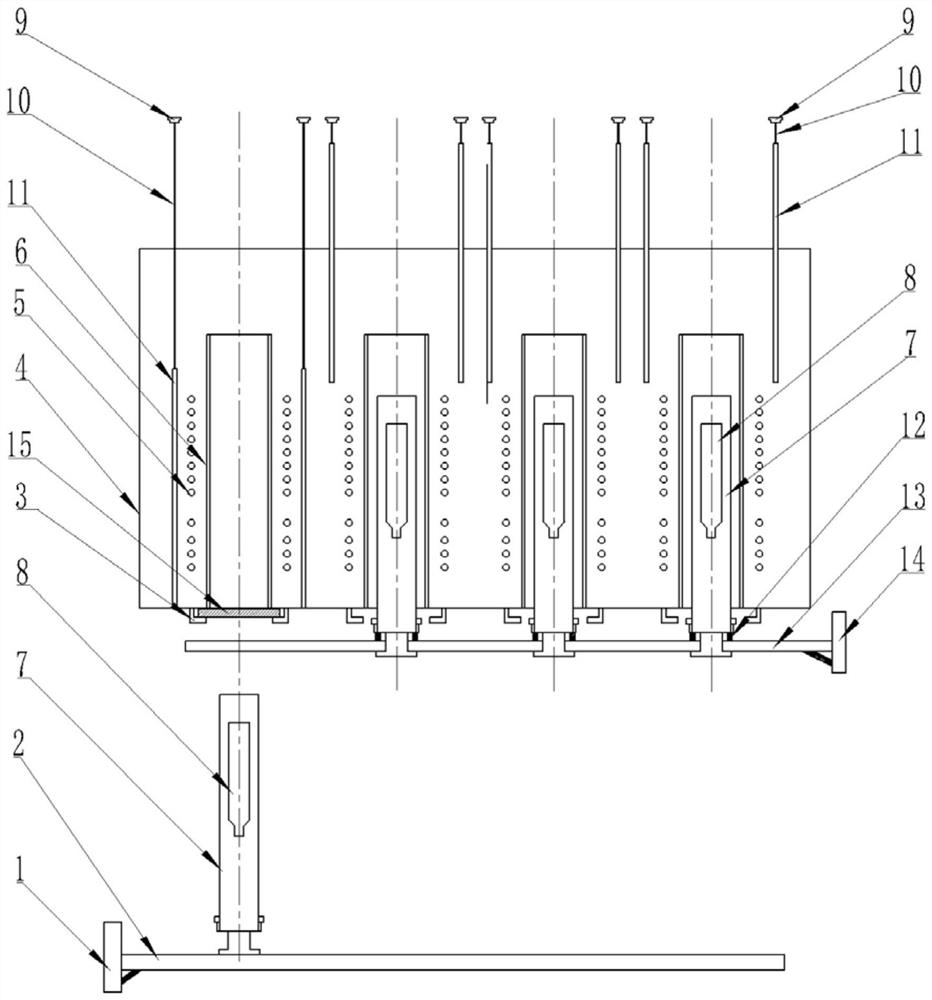

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] see figure 1 with figure 2 , a multi-crucible crystal growth furnace whose stations can be independently controlled, including a furnace body, a station lifting control device and a station heat insulation device. The furnace body has 4 to 6 single crystal growth stations, and the single crystal growth station is set The crystal growth unit has a circular structure; the heating element of the crystal growth unit is an annular heating element 5, which adopts an annular silicon-molybdenum rod and is vertically hoisted in the furnace body, and is lined with a uniform temperature tube 6 between the annular heating element 5 and the down-conducting tube 7 , the temperature field distribution of the single crystal growth station is uniform, which has little effect on crystal growth and is conducive to the growth of high-quality crystals; the temperature field of each si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com