Thin film bulk acoustic resonator and its processing method

A thin-film bulk acoustic wave and resonator technology, applied in impedance networks, electrical components, etc., can solve the problems affecting the performance of thin-film bulk acoustic wave resonators, affecting the growth of high-quality piezoelectric layers, etc., to avoid incomplete release and adhesion problems. , get high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

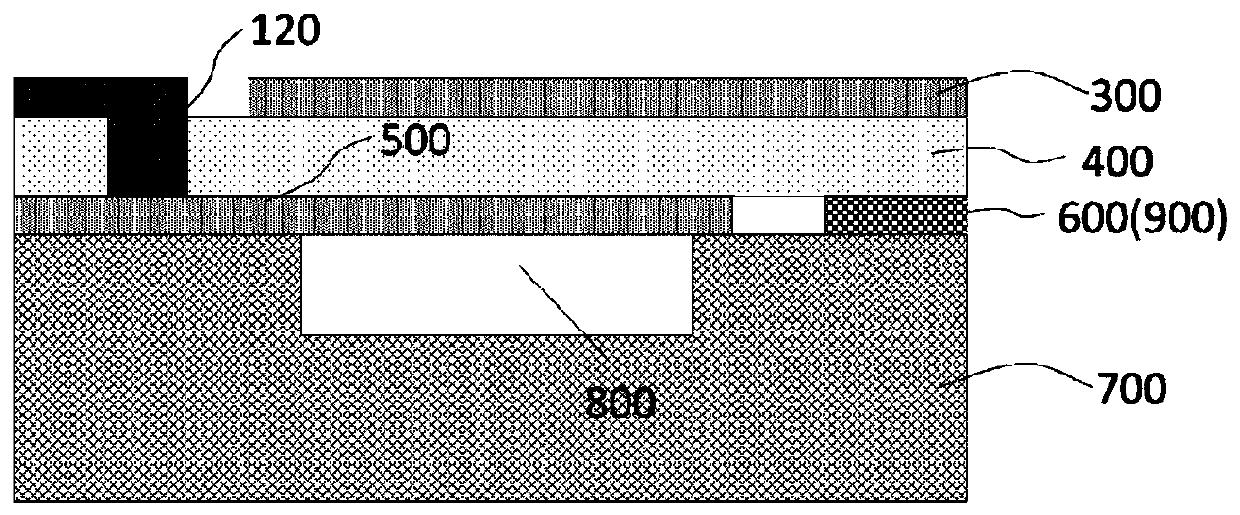

[0030] figure 1 It is a cross-sectional structure diagram of a thin film bulk acoustic resonator according to an embodiment of the present invention, the thin film bulk acoustic resonator includes a substrate 700, the substrate 700 is, for example, a silicon wafer; the substrate 700 includes an air gap 800; a bonding layer 600 (900), bonding layer is for example gold etc.; Including piezoelectric sandwich structure above air gap 800, wherein 500 is the first electrode of piezoelectric sandwich structure, and material is molybdenum etc.; 400 is the piezoelectric layer of piezoelectric sandwich structure , the material is a piezoelectric single crystal, such as piezoelectric quartz, lithium tantalate, lithium niobate or lithium tetraborate, etc.; 300 is the second electrode of the piezoelectric sandwich structure, and the material is molybdenum, etc.; the interconnection metal 120 is the piezoelectric sandwich The first electrode of the structure is led out to the surface of 400...

Embodiment 2

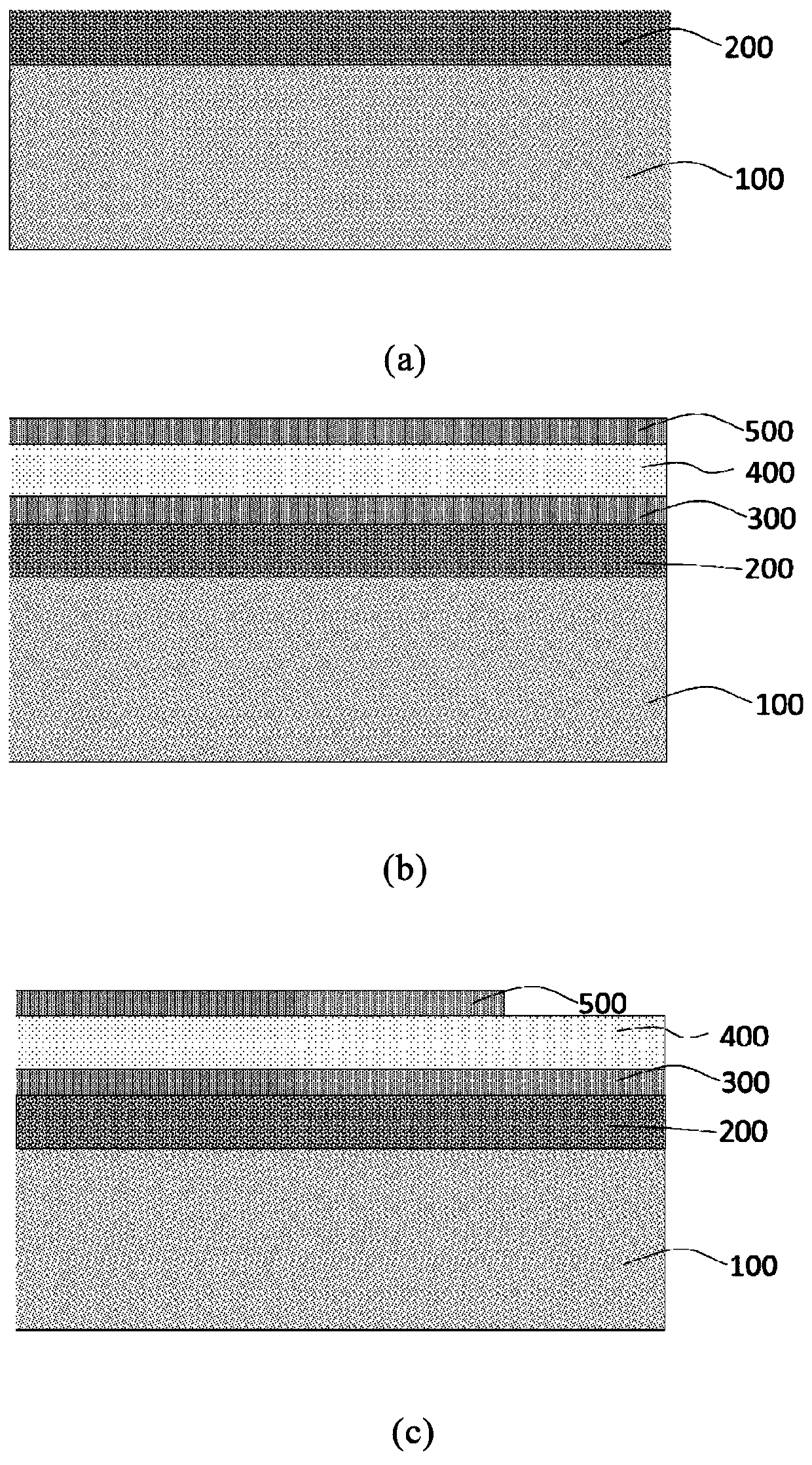

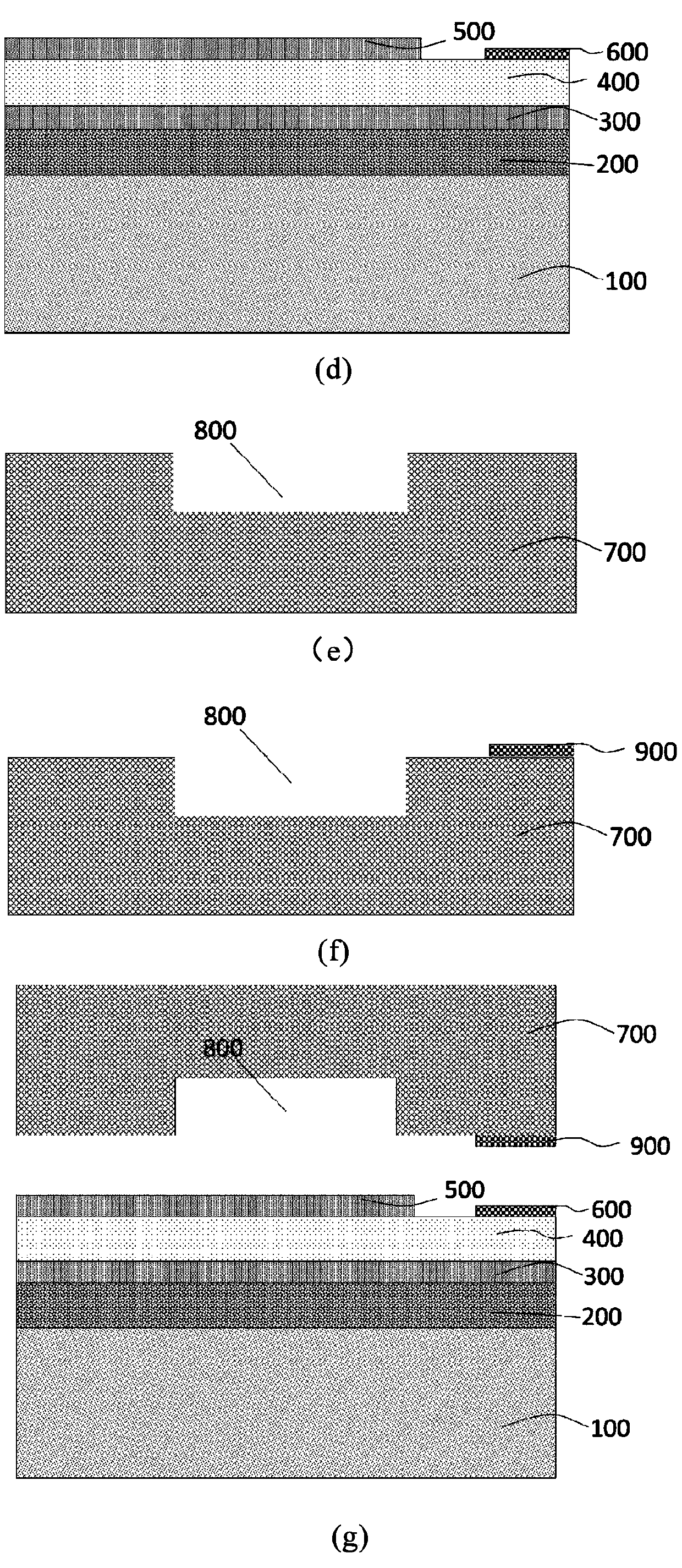

[0032] figure 2 It is a flow chart of the preparation process of a thin film bulk acoustic resonator according to an embodiment of the present invention, and the preparation process includes:

[0033] (a) Prepare a silicon wafer 100 polished on one or both sides, with the polished side up, and perform standard cleaning.

[0034] (b) Depositing a layer of thin film material 200 for subsequent peeling. The material can be silicon dioxide, silicon nitride, phosphosilicate glass and other materials that are easy to peel off from the silicon substrate.

[0035] (c) Depositing the second electrode 300 , the piezoelectric material 400 and the first electrode 500 sequentially on the thin film material 200 . Wherein, the first electrode 500 and the second electrode 300 include molybdenum electrodes, and the piezoelectric material 400 includes one or a combination of aluminum nitride (AlN), zinc oxide (ZnO), lithium niobate (LiNbO3), lithium tantalate (LiTaO3) .

[0036] (d) pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com