Weaving method of flat knitting three-dimensional corrugated fabric

A technology of flat knitting and corrugation, applied to weft knitting, flat knitting machines with individual moving needles, knitting, etc., can solve problems such as difficult mass production, and achieve the goals of improving production efficiency, reducing labor procedures, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

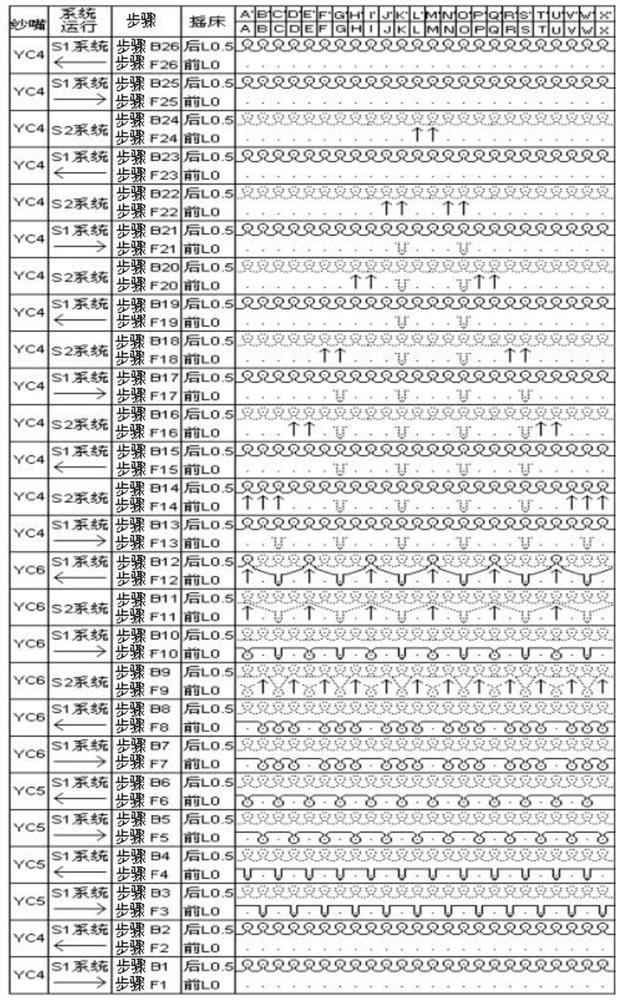

[0038] Such as figure 1 Shown is a schematic diagram of the weaving method for weaving three-dimensional corrugated strip fabrics on a flat knitting machine in the present invention.

[0039] In the figure, the S+ number marked in the left column indicates the double-system knitting of the computerized flat knitting machine, S1 indicates the 1-system knitting, and S2 indicates the 2-system knitting; indicates each knitting needle, and the B+ number indicates the row of knitting on the back panel; F+ The number indicates the knitting row of the front plate; L0 indicates that the needle positions of the front and rear needle plates are aimed at the teeth; L0.5 indicates that the needle positions of the front and rear needle plates are aimed at the needles; Indicates positive needle coil; Indicates a reverse stitch;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com