Corrugated web steel wood composite beam and assembly joint

A steel-wood combination and corrugated web technology, which is applied to structural elements, building components, and elongated structural components for load-bearing, can solve problems such as loss of bearing capacity, twisting deformation, lateral torsion instability, etc. Simple and safe, good anti-twisting performance, and the effect of improving the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

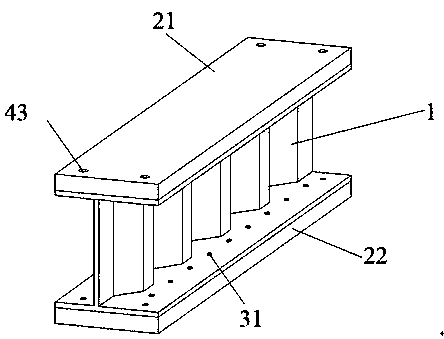

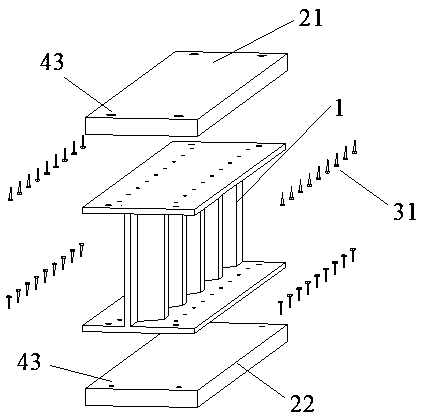

[0040] Such as figure 1 As shown, a typical steel-wood composite beam in this design is composed of a corrugated web steel beam 1, an upper plank 21, a lower plank 22 and wood screws 31, and the upper and lower planks are made of glulam. The webs 1-3 can be designed to be wavy, zigzag, trapezoidal, curved, rectangular, or zigzag. Here, a steel girder with zigzag webs is used as an example for expression.

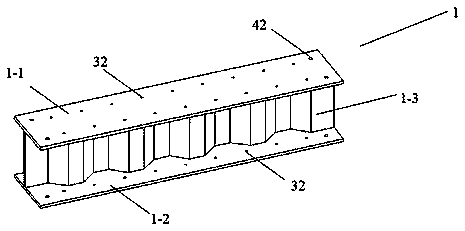

[0041] Such as figure 2 As shown, on the upper flange 1-1 and the lower flange 1-2 of the corrugated web steel beam 1, screw holes 32 for wood screws 31 are set at a certain distance, and the four corners of the steel beam flange are set as the first high-strength The sixth bolt hole 42 that bolt is reserved. For ease of understanding, here is an example of setting a bolt hole at each corner. In actual engineering, bolt holes can be added on the upper and lower flanges according to the size of the component, the load-bearing condition and the needs of the connection betwe...

Embodiment 2

[0045] As shown in 5, the first box-shaped connector 51 includes a back plate 51-1, upper and lower top plates 51-2, and left and right side plates 51-3, and the upper and lower top plates 51-2 are provided with the first bolts reserved for the first high-strength bolts Hole 44.

[0046] Such as Image 6 with Figure 7 As shown, when two steel-wood composite beams are connected horizontally and forwardly, a first box-shaped connector 51 is installed on both sides of the web 1-3 at the joint, and the first high-strength bolt 41 is used to connect the first The box-shaped connector 51, the upper and lower flanges of the corrugated web steel girder 1, and the upper plank 21 and the lower plank 22 are connected to form a firm whole. The first back plate 51-1 and the first upper and lower top plates 51-2 of the first box-shaped connector 51 can provide better shear performance at the connection, and the left and right side plates 51-3 are similar to the stiffeners at the beam end...

Embodiment 3

[0048] Such as Figure 8 As shown, when two steel-wood composite beams are connected vertically and are connected at the ends of the two beams, a bolt hole for the first high-strength bolt 41 needs to be pre-set on one of the beams (including steel beams and upper and lower planks). In the actual engineering of multi-storey timber structures, this type of vertical connection is basically the connection between the main beam and the secondary beam, and the additional bolt holes should be set on the main beam.

[0049] Such as Figure 9 with Figure 10 As shown, the first box-shaped connector 51 conflicts with the space position of the screw head of a wood screw 31 of the beam, and a groove 52 is opened on the first box-shaped connector, so that when the first box-shaped connector 51 is assembled By avoiding the screw head of the wood screw 31 , the tight fit between the first box-shaped connector 51 and the flange of the steel beam 1 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com