Pneumatic pressing machine for electric engineering

A technology of electric power engineering and crimping machine, which is applied in the field of electric power and can solve problems such as component jamming, inability to slide, and mechanical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

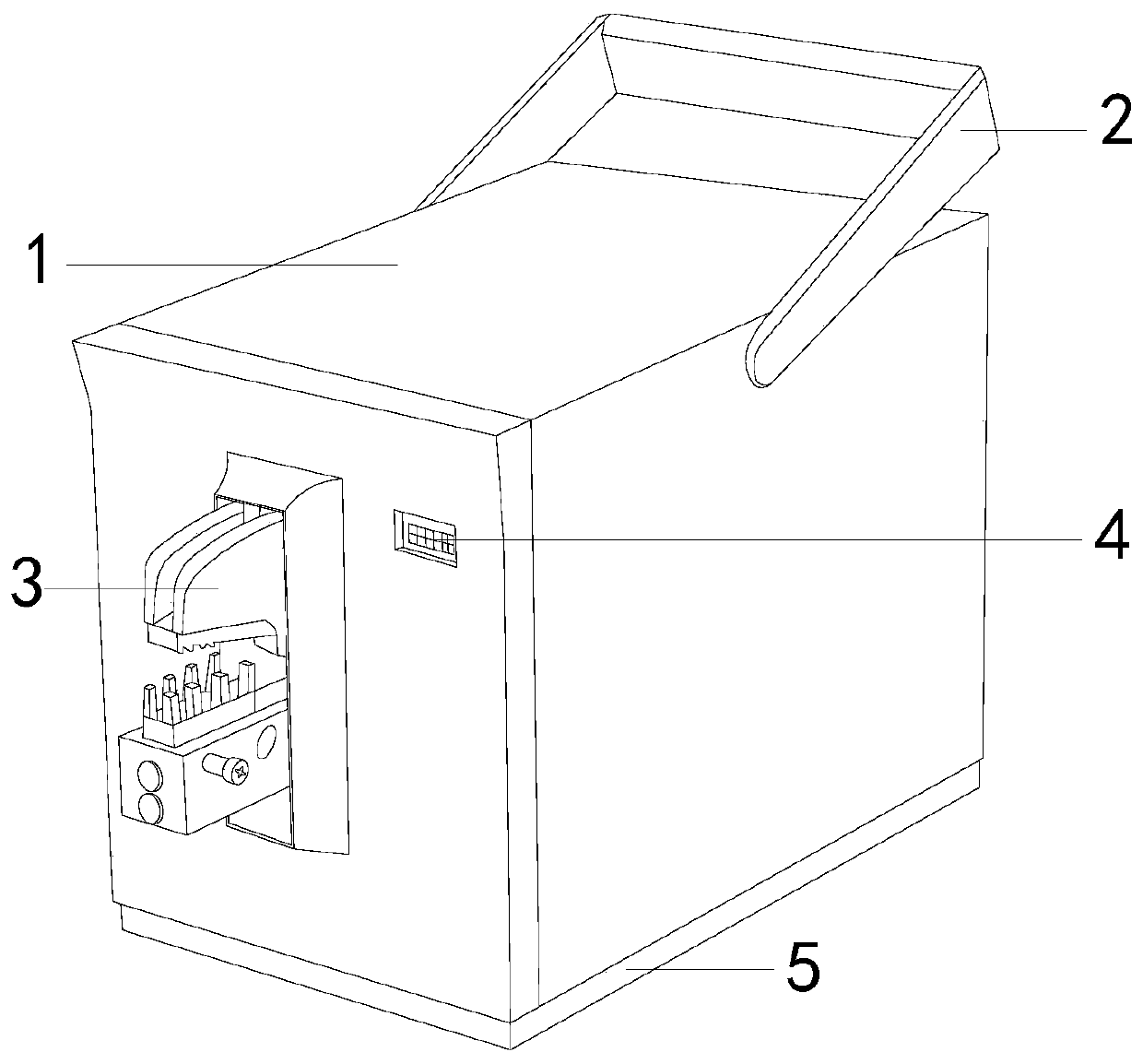

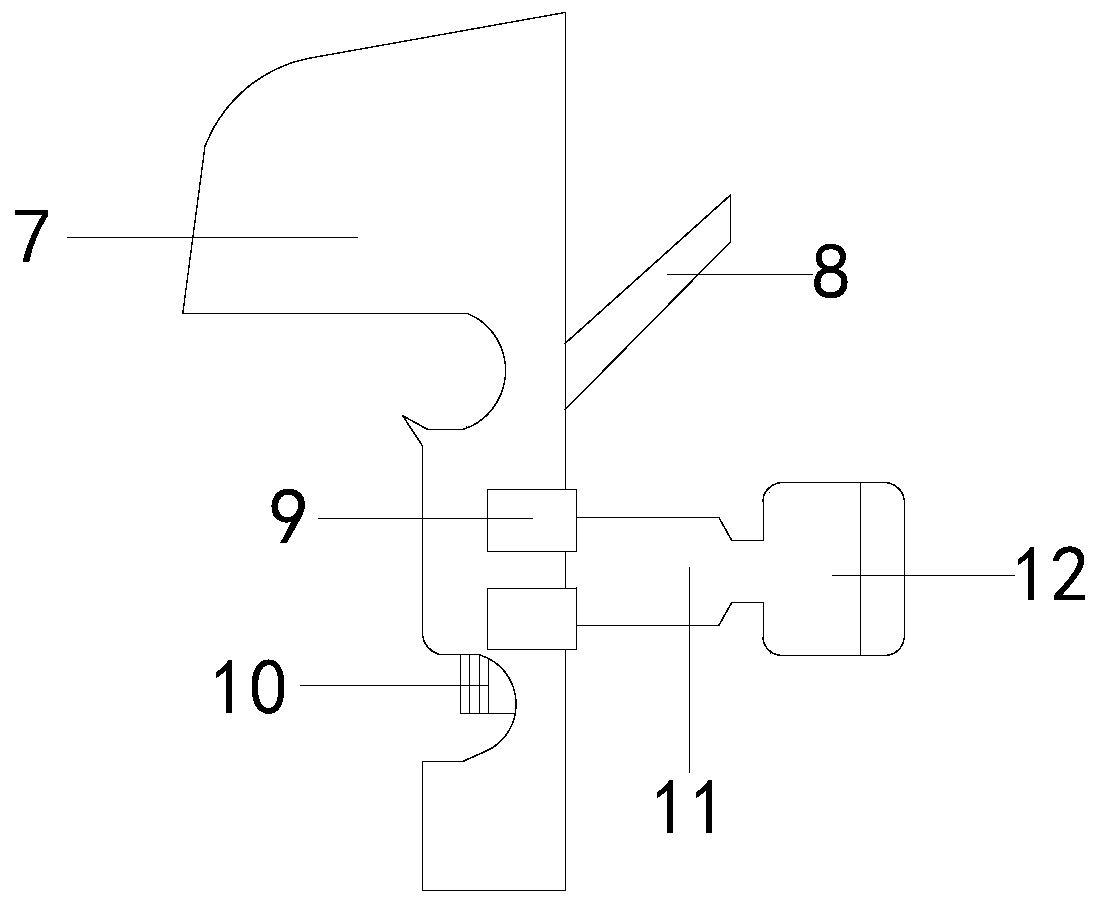

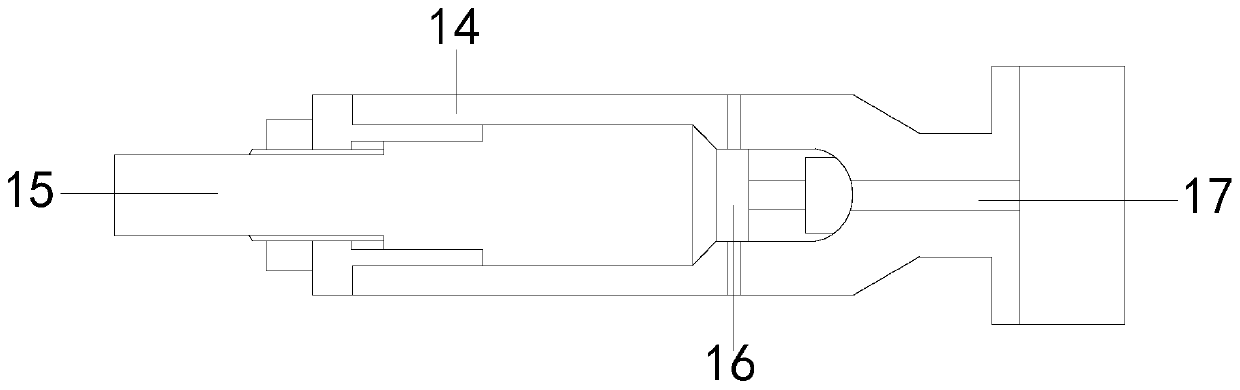

[0020] see figure 1 , the present invention provides a pneumatic crimping machine for electric power engineering. Its structure includes: a main body 1, a handle 2, a molding mechanism 3, a counter 4, and a bottom plate 5. Connected, the die mechanism 3 is arranged on the front side of the main body 1 and is connected to the inside. The main body 1 is provided with a counter 4 and a bottom plate 5 is installed at the bottom of the main body 1. The driving components together form a complete main structure, and the inside of the main body is driven by a motor plus a frequency converter. This structure has no mechanical failures of traditional clutches, can simplify internal mechanical parts, reduce wear and replacement of mechanical parts, and has high torque and low vibration. , high stability, which helps to improve the ultra-quiet working performance. The handle 2 is used to lift the equipment so that it has the function of application in different places and portable movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com