Swing type drying oven device for tea drying

A swing type, oven technology, applied in tea drying, drying, dryer and other directions, can solve the problems of poor tea drying effect, single drying structure, low efficiency, etc., to improve drying and dust filtering effect, good Stirring effect, good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

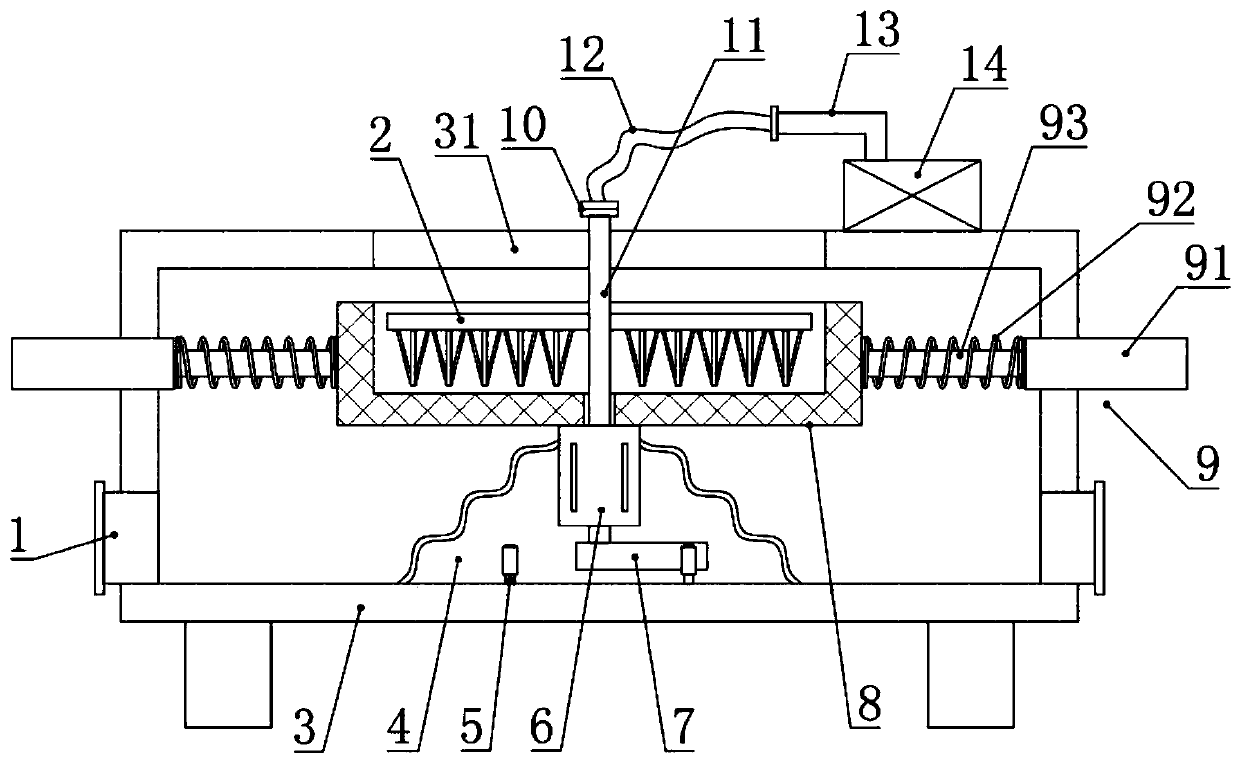

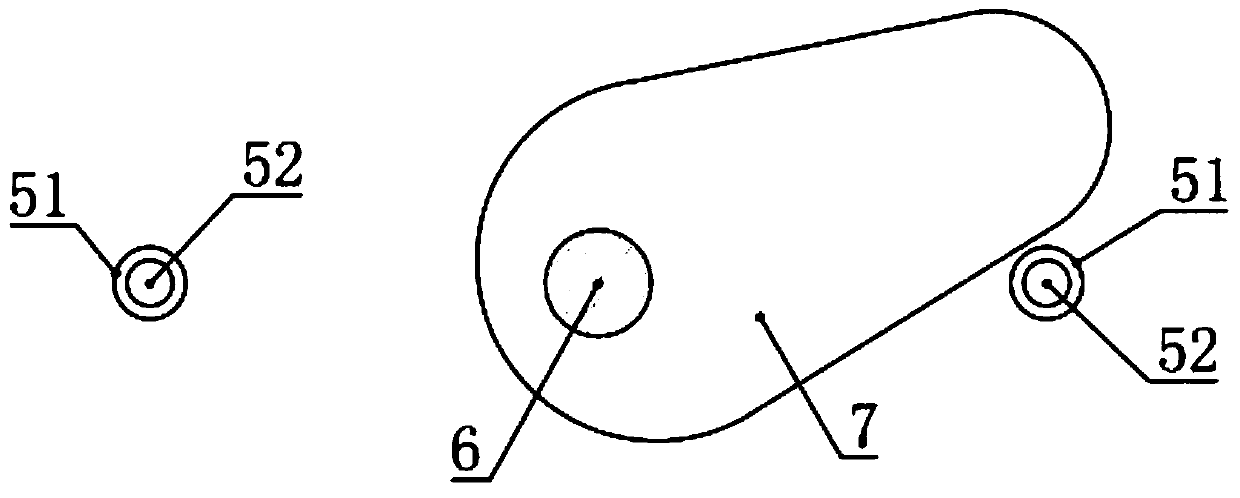

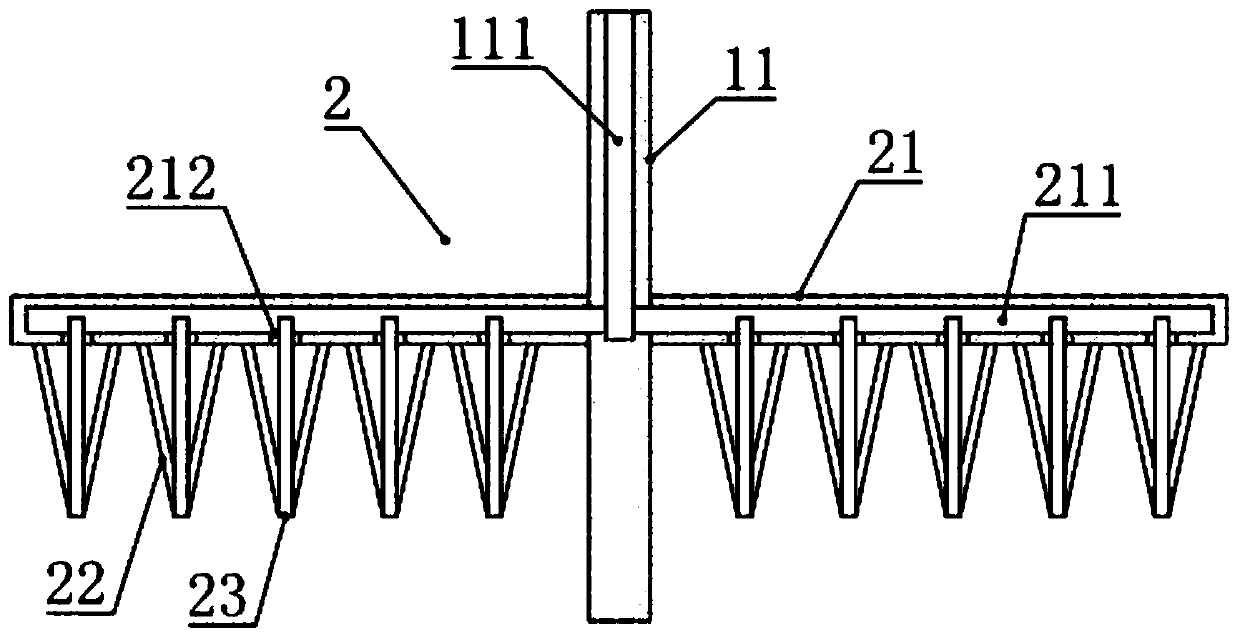

[0026] see figure 1 , in an embodiment of the present invention, a swing-type oven device for drying tea leaves, comprising a box body 3, the inner side of the box body 3 is provided with a loading net box 8 with an upper opening, and the left and right sides of the box body 3 An elastic telescopic assembly 9 is respectively installed and fixed on the wall, and the inner end of the elastic telescopic assembly 9 is connected and fixed with the loading net box 8, and the elastic telescopic assembly 9 can stably support the loading net box 8 and facilitate the loading net The left and right movement of the box 8; the bottom of the loading net box 8 is fixed with a biaxial extension motor 6, and a cam 7 is installed and fixed on the lower output shaft of the biaxial extension motor 6, and the left and right sides of the bottom of the box 3 The side is correspondingly provided with a toggle assembly 5 that can be linked with the cam 7; the upper output shaft of the biaxial extensio...

Embodiment 2

[0028] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0029] In this example, if figure 1 As shown, the top of the box body 3 is provided with an inlet and outlet 31 compatible with the loading cage 8, and the inlet and outlet 31 are used for picking and placing tea leaves in the loading cage 8.

[0030] In this example, if figure 1 As shown, the elastic telescopic assembly 9 includes a mounting cylinder 91, a spring 92 and a telescopic rod 93, the mounting cylinder 91 is fixed on the side wall of the box body 3, and the mounting cylinder 91 is provided with a telescopic rod 93 for cooperation and sliding. The inner end of telescopic rod 93 is fixed on the loading net box 8, and also is provided with spring 92 on the telescopic rod 93 between described installation tube 91 and loading net cage 8, can be loaded with material net cage 8 by spring 92. Elastic support is beneficial to return to the original position after the material-carrying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com