Targeted shear wave elastography detection system and detection method thereof

An elastography and detection system technology, applied in measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as accuracy and reliability, hindering ultrasonic transmission, and affecting the sensitivity of shear wave elastography. , to achieve the effect of improving penetration, improving sensitivity, and accurate and reliable detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] refer to Figure 1 to Figure 4 .

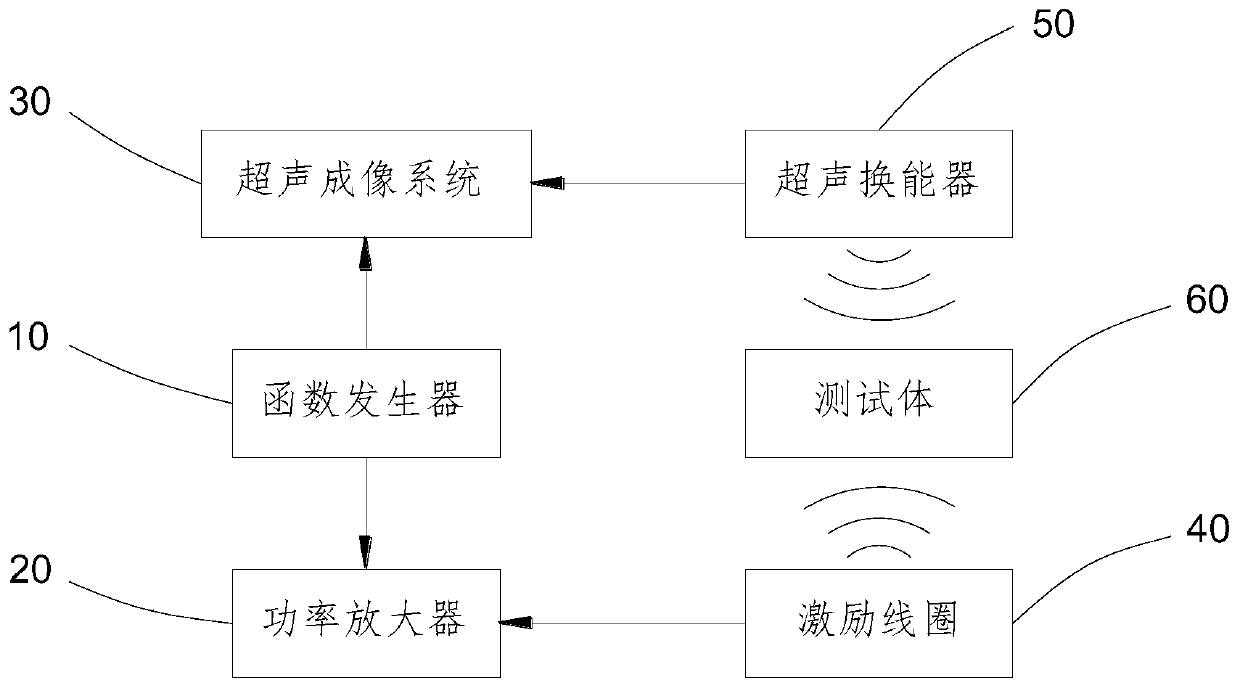

[0029] The embodiment of the present invention discloses a targeted shear wave elastography detection system, such as figure 1 As shown, it includes a function generator 10, the output end of the function generator 10 is respectively connected to a power amplifier 20 and an ultrasonic imaging system 30, the output end of the power amplifier 20 is connected to an excitation coil 40, and the data acquisition end of the ultrasonic imaging system 30 is connected to a Between the ultrasonic transducer 50 and the excitation coil 40 and the ultrasonic transducer 50, a test body 60 containing magnetic particles inside is provided.

[0030] In this embodiment, the ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com