Overall calibration system and method for current transformer on-site calibrator

A current transformer and on-site calibration technology, which is applied in the field of transformer detection, can solve the problems of different working principles, different verification methods, and sub-component verification not equal to overall verification of the current transformer on-site calibrator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

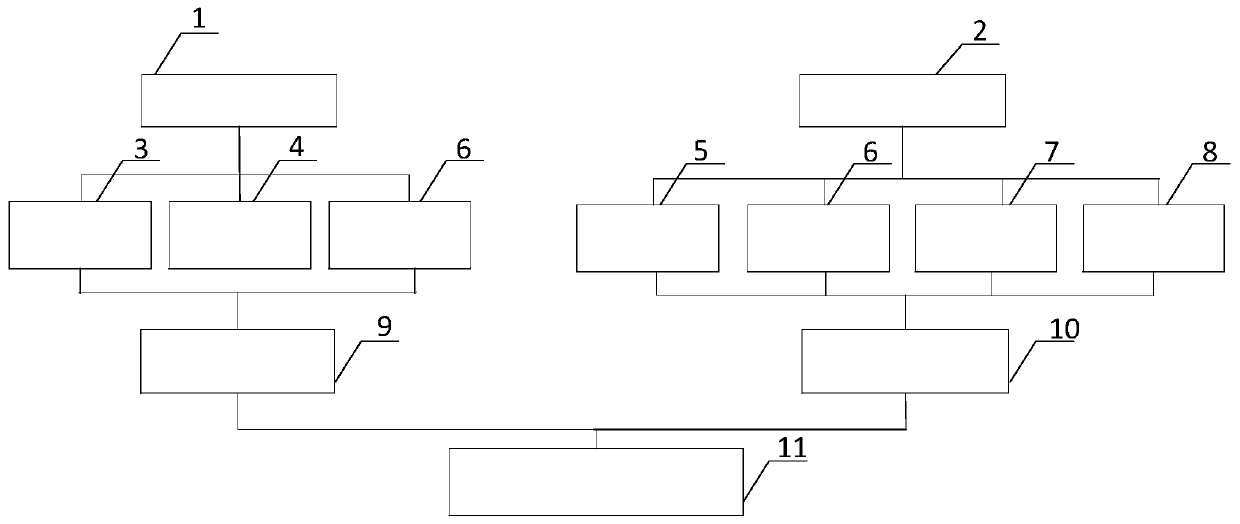

[0057] like figure 1 As shown in the figure, the overall verification system of the current transformer field calibrator includes the overall verification system 1 of the current type current transformer field calibrator, the overall verification system 2 of the voltage type current transformer field calibrator and the whole machine verification data management system 11 ;

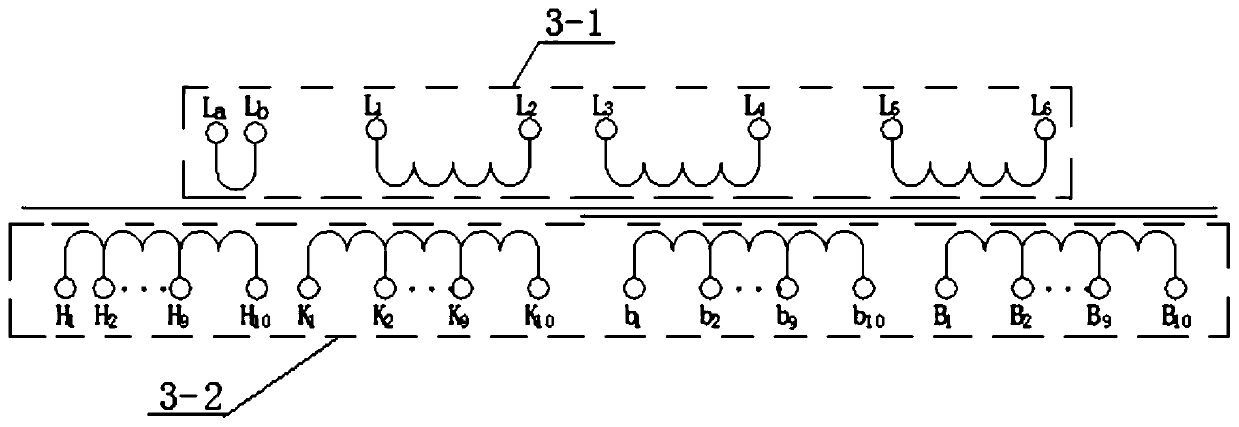

[0058] The overall verification system 1 of the current-type current transformer field calibrator includes a current proportional standard 3, a standard ammeter 4 and a non-compensated standard current transformer 6. The current proportional standard 3 is used to verify the current-type built-in standard. The standard ammeter 4 is used for calibrating the error loop and dial indicator loop of the built-in calibrator of the current type; ;

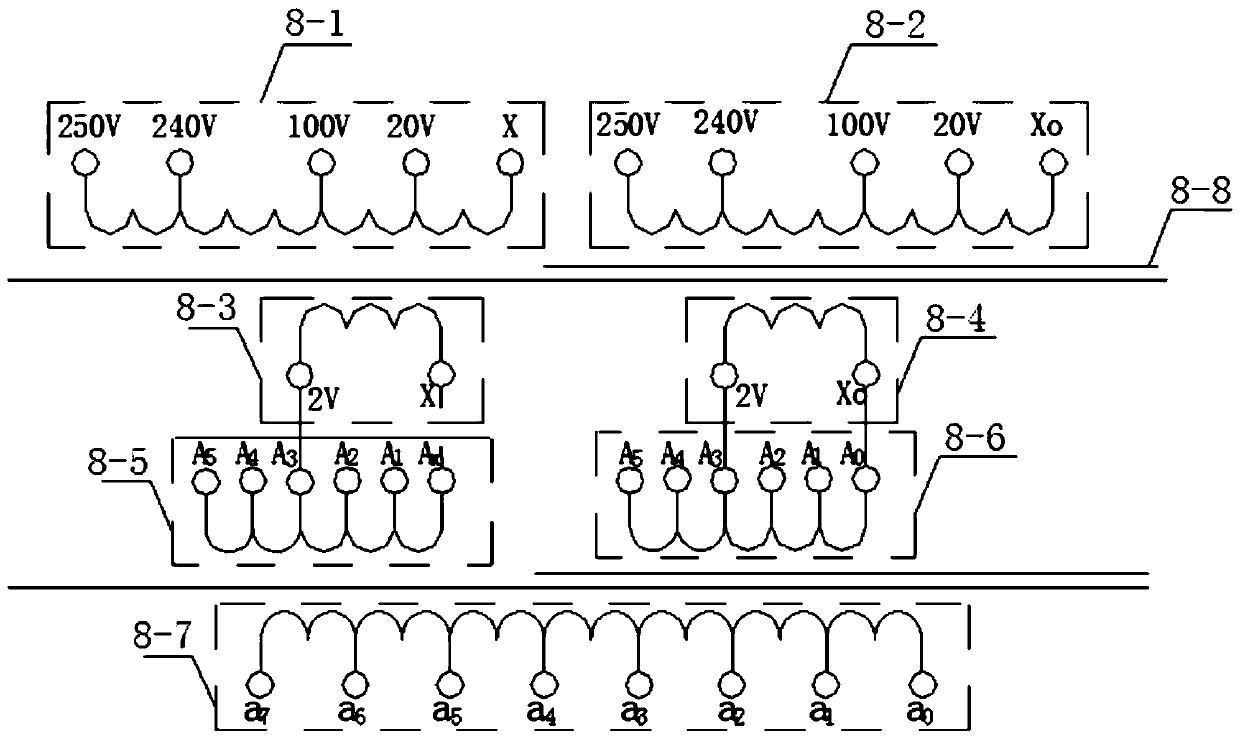

[0059] The accuracy level of the voltage ratio standard 8 is level 0.005;

[0060] like figure 2 As shown in the figure, the voltage proportional standard primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com