Hollow block formwork-free constructional column synchronous infilled wall construction method based on BIM technology

A hollow block and structural column technology, applied in data processing applications, instruments, geometric CAD, etc., can solve problems such as affecting the progress of wall plastering, increasing the construction period of structural columns, affecting the appearance of structural columns, etc., to reduce quality risks, Shorten the construction period and achieve the effect of free formwork construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

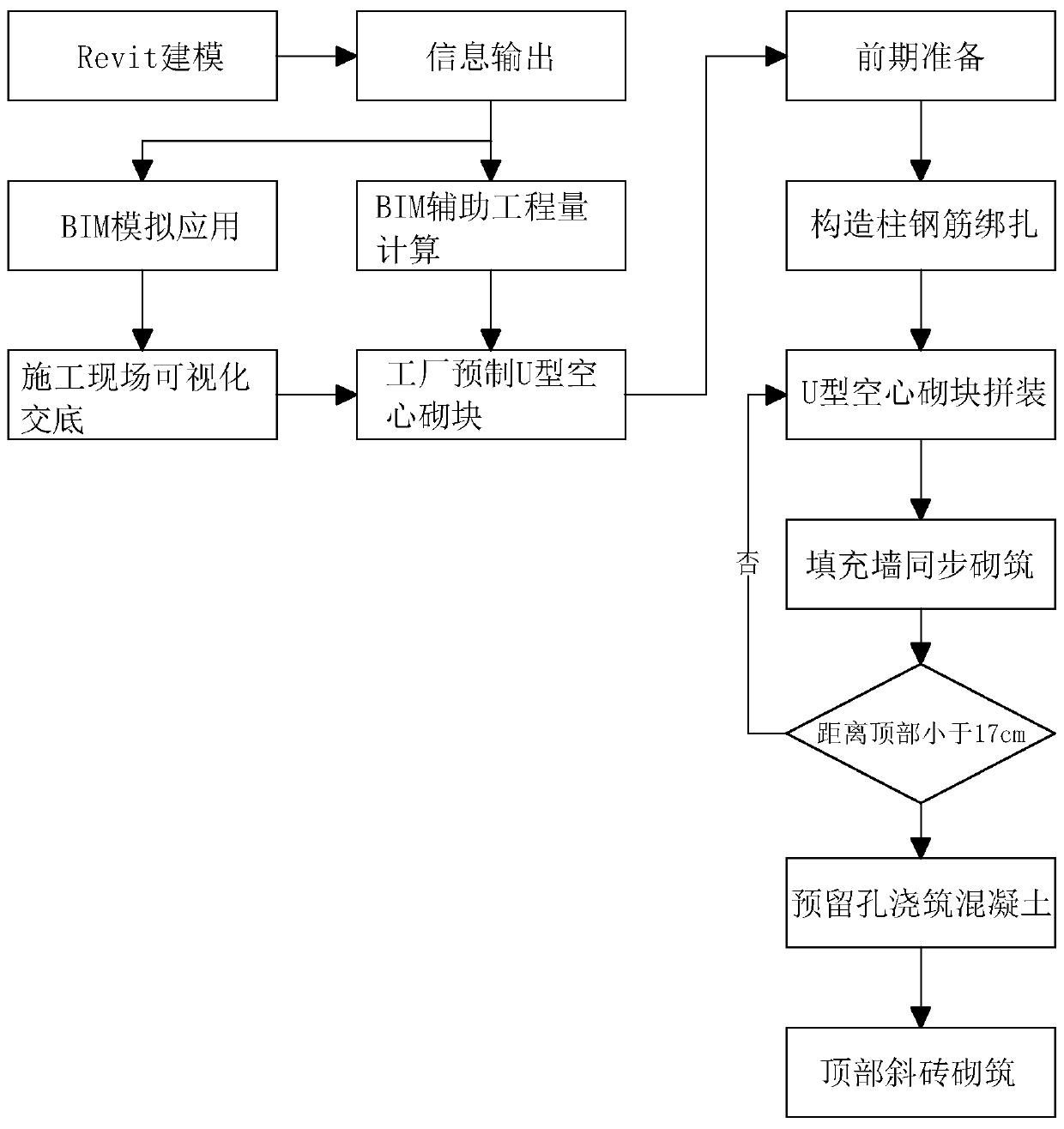

[0037] pass figure 1 To further describe the present invention,

[0038] A construction method based on BIM technology for hollow block formwork-free construction column synchronous filling wall, characterized in that it includes the following steps:

[0039] S1: REVIT modeling steps are as follows:

[0040] a. Organize professional construction workers, engineering technicians, BIM engineers, familiar with the drawings, on-site positioning and measurement;

[0041] b. Use BIM technology to conduct 3D modeling according to the construction drawings of structural columns and infill walls

[0042] c. Check the parts that are not clearly marked on the drawings, the parts where the clear height is not enough, the parts where the components conflict, etc.,

[0043] d. Form a self-examination record for the contradictory problems among the professional drawings of the construction drawings and the problems that may be encountered during the construction process;

[0044] e. Comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com