Instrument pointer reading automatic identification method and system

An instrument pointer and automatic recognition technology, which is applied in the direction of character and pattern recognition, instruments, biological neural network models, etc., can solve the problems of high labor cost, affecting pointer recognition, low efficiency, etc., and achieve the goal of increasing the production rate and reducing the difficulty of recognition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

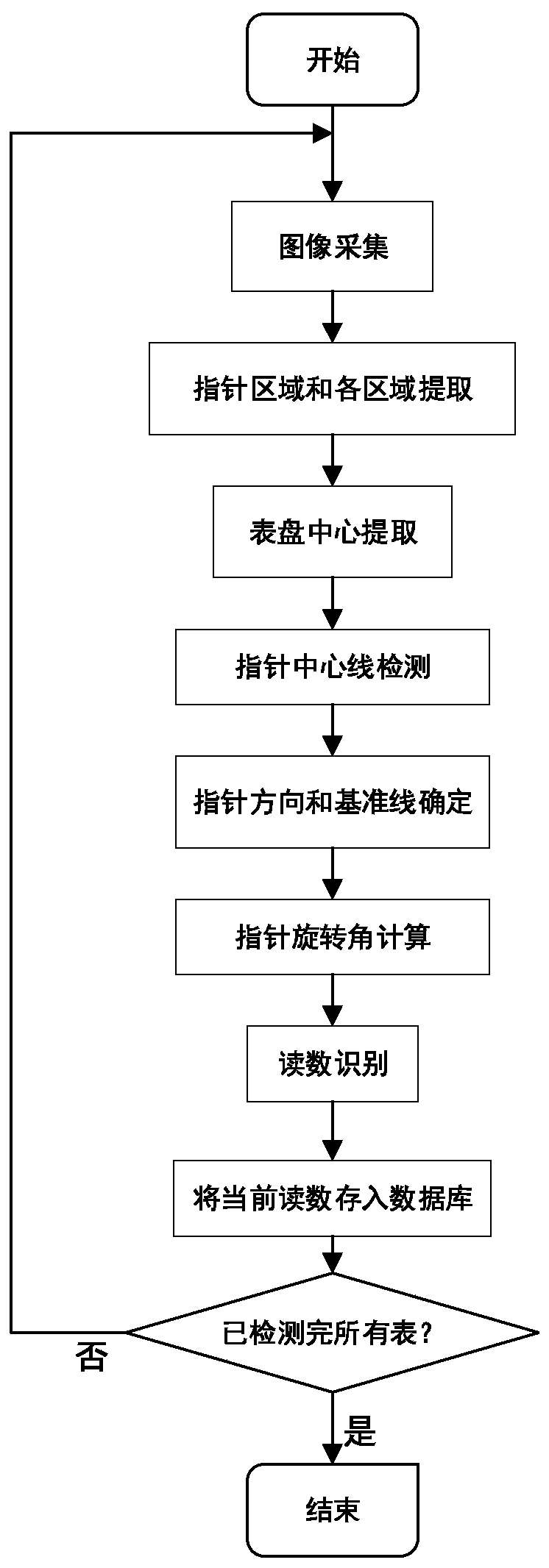

[0029] Such as figure 1 As shown, it is a flow chart of the present invention, a method and system for automatic recognition of instrument pointer readings based on vision, comprising the following steps:

[0030] Step 1: Build a hardware platform for image collection. Under a fixed light source, use a camera to take pictures and collect watch images.

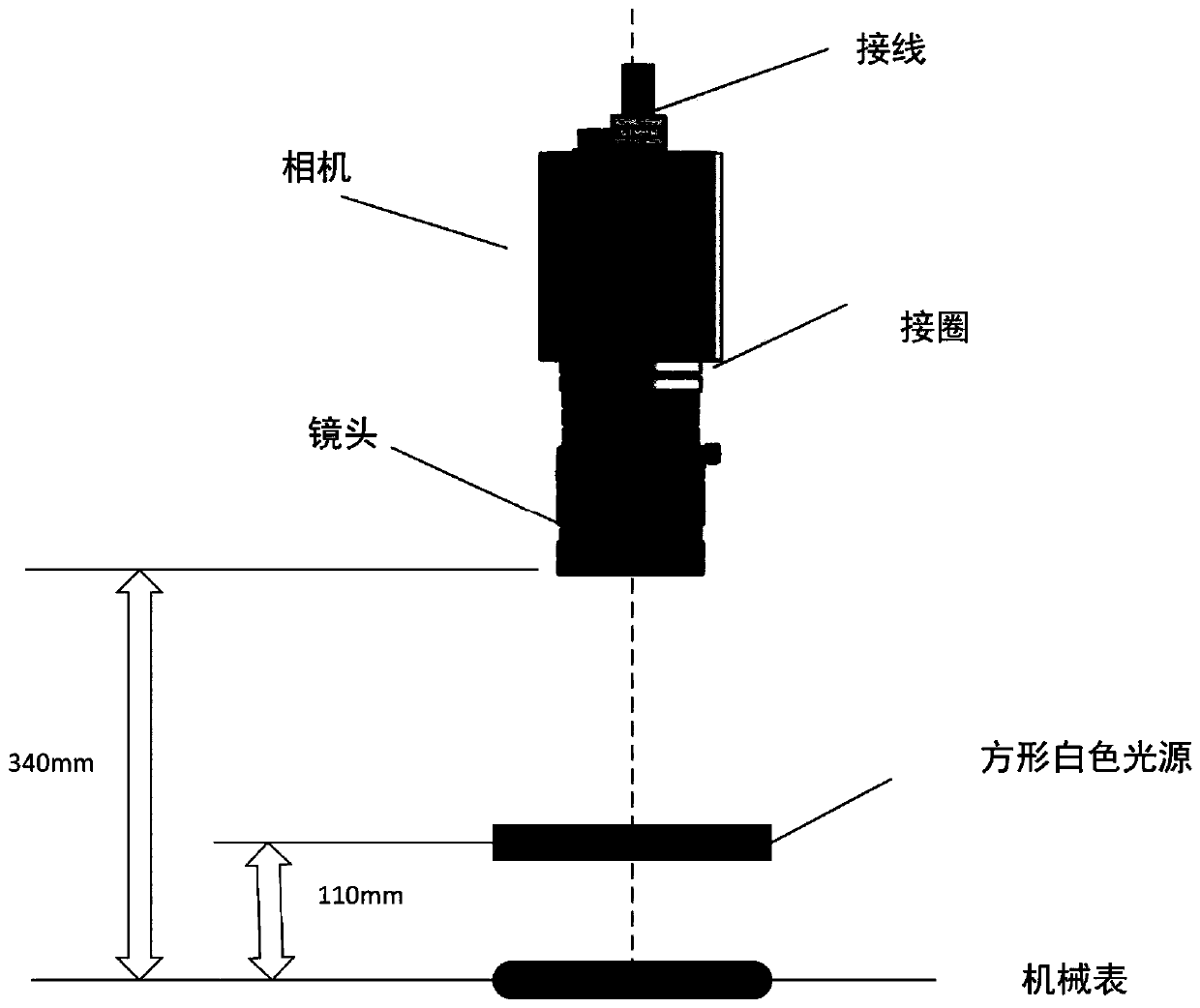

[0031] The hardware platform such as figure 2 As shown, the hardware platform is composed of camera, lens and light source. When collecting pictures, the watch is placed in the watch box, the watch box is fixed on the deck, the light source is used for lighting, and the camera takes pictures. Lighting main view as figure 1 shown.

[0032] Step 2: Mark the hour hand, minute hand, second hand, 12 o'clock, and 6 o'clock on the image collected in step 1, send it to the neural network for training, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com