Self-shielding cold-insulation direct-current high-temperature superconducting current-limiting cable

A high-temperature superconducting, self-shielding technology, applied in superconducting devices, superconducting/high-conducting conductors, usage of superconducting elements, etc., can solve problems such as high cost, increased line construction cost, and increased line maintenance cost, etc. Achieve the effect of reducing device cost, increasing critical current, and reducing operation and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

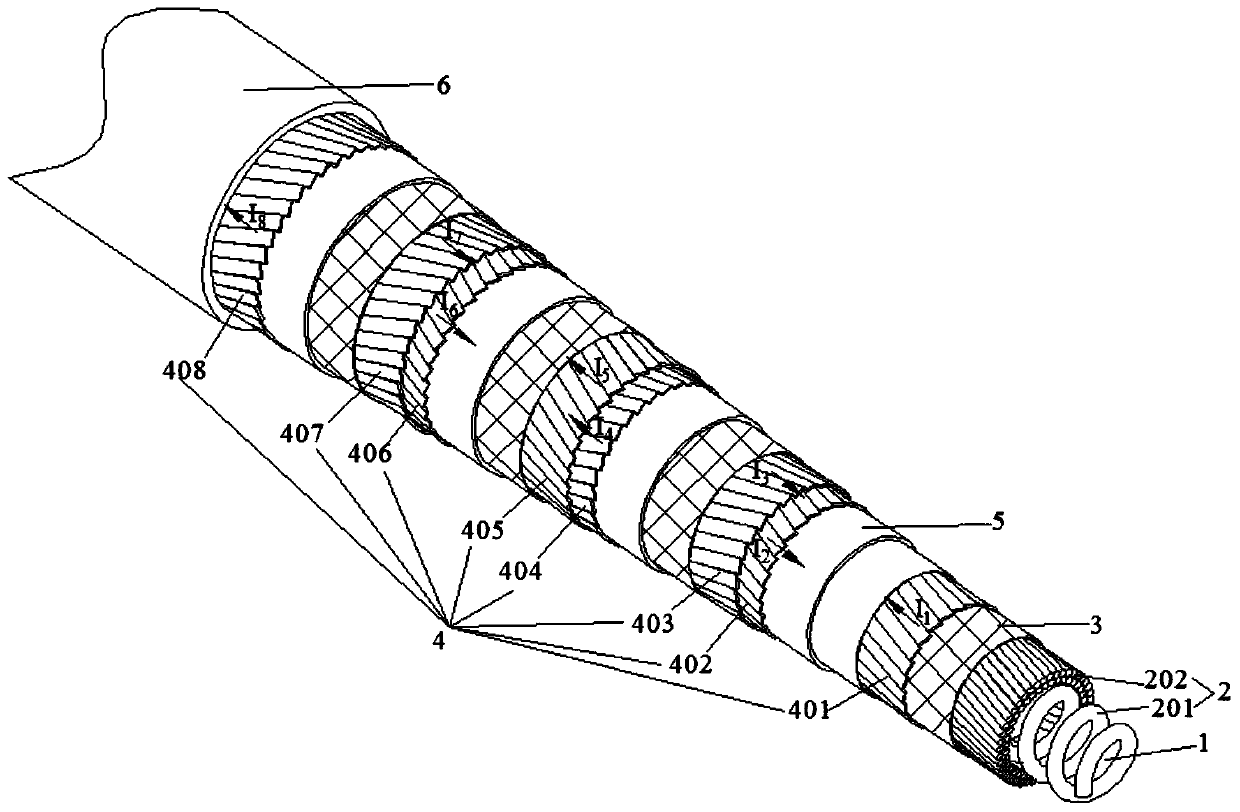

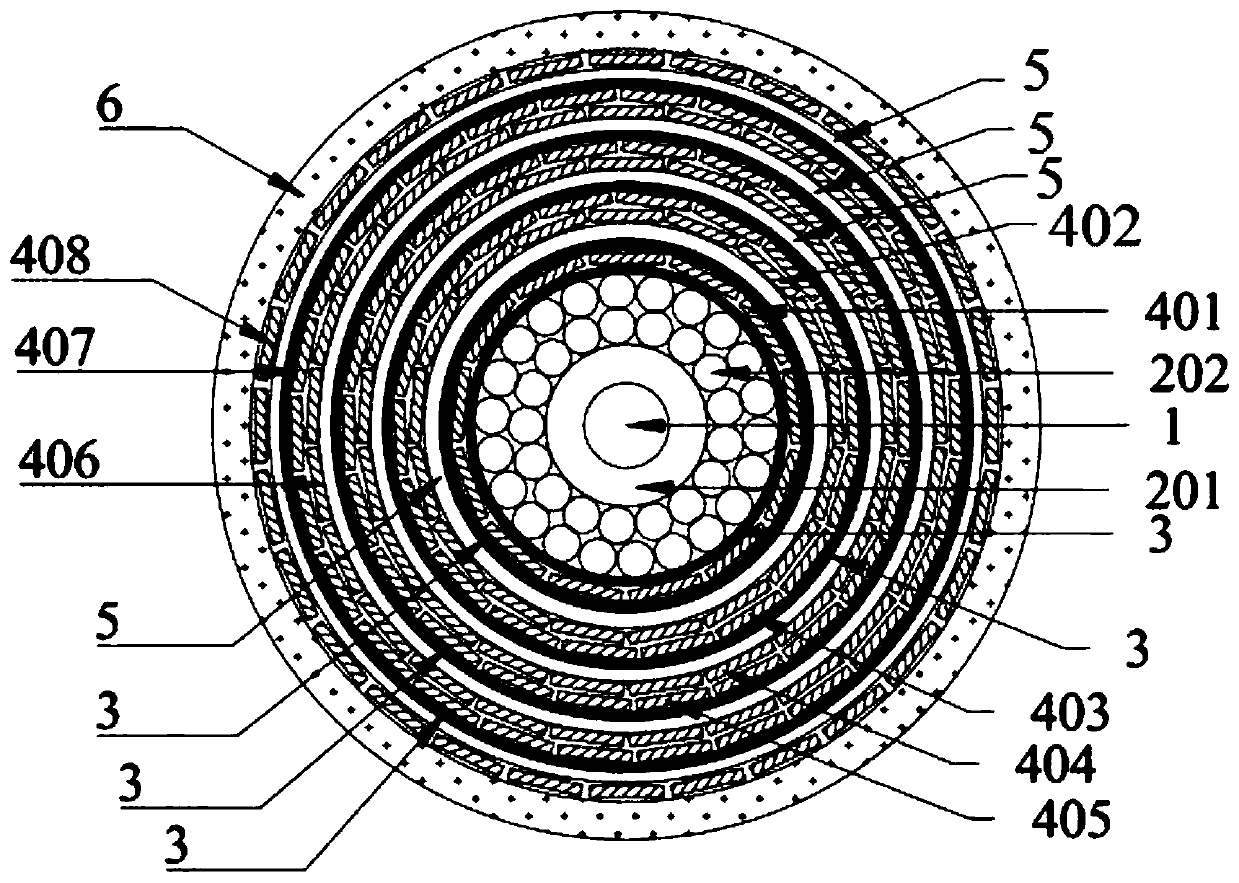

[0021] as attached Figure 1-2 As shown, a self-shielding cold-insulated DC high-temperature superconducting current-limiting cable includes a cooling channel 1, a cable skeleton 2, a semiconductor layer 3, a superconducting layer 4, an insulating layer 5 and a protective layer 6; the superconducting layer 4 includes Superconducting odd-numbered layer n and superconducting even-numbered layer 2n, wherein n is a positive integer greater than or equal to 1; the cable skeleton 2 includes a coil spring 201 and a twisted wire 202 wound outside the coil spring; the inside of the coil spring 201 A cooling channel is formed; the cooling channel 1 is located in the center of the cable skeleton 2; the cooling channel 1 is used to circulate cooling media such as liquid nitrogen to ensure that the superconducting cable is in a temperature environment required for normal operation; the cable skeleton 2 is set outside There is a semiconductor layer 3; a superconducting odd-numbered layer n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com