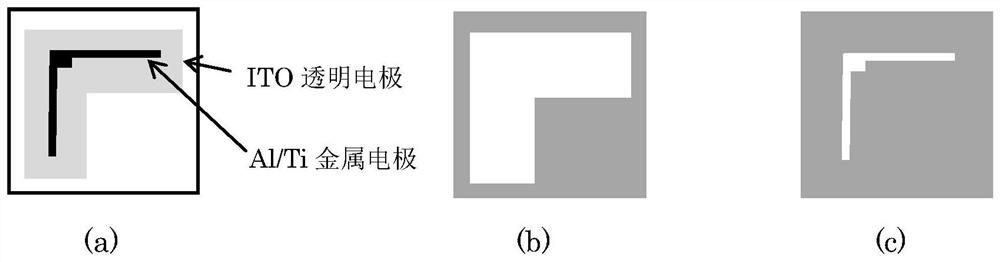

A kind of P-type composite electrode material of Gan-based LED suitable for aluminum wire pressure welding and its preparation method

A composite electrode, aluminum wire pressure welding technology, used in circuits, electrical components, semiconductor devices, etc., can solve the problems of influence, poor light transmission, etc., and achieve the effect of reducing cost, stable performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

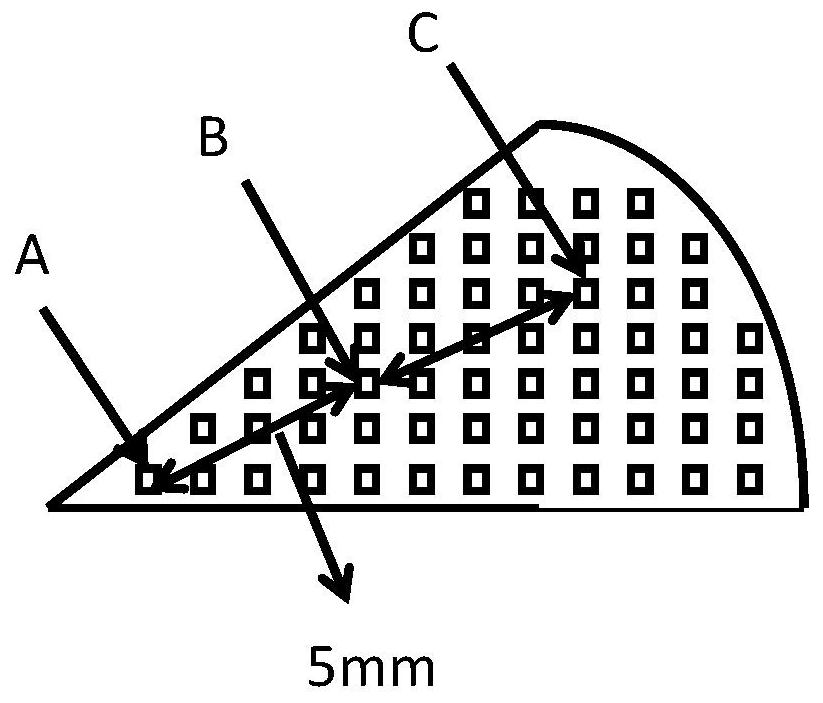

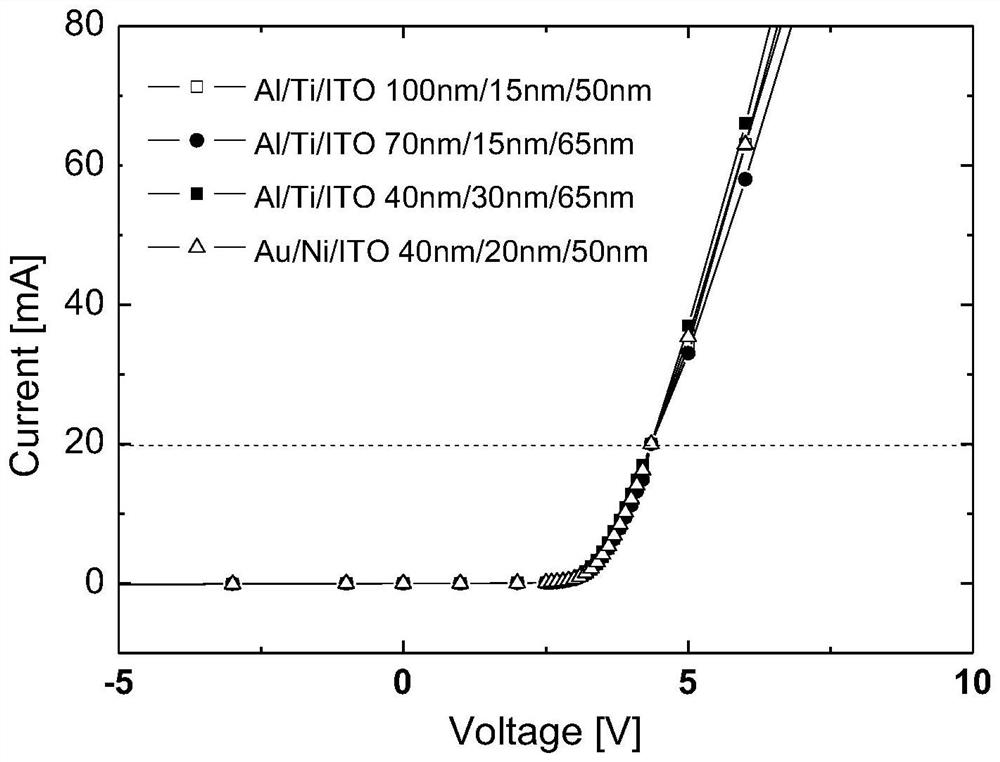

Method used

Image

Examples

Embodiment 1

[0041] (1) prepare the ITO raw material that purity is 99.999%, wherein SnO 2 The doping amount is 5wt%, In 2 o 3 The content is 95wt%;

[0042] (2) Put the ITO raw material in step (1) into the EB raw material boat, put the GaN sample carrying the P-type transparent electrode mask pattern after exposure and development on the sample holder, and the area not covered by the photoresist is transparent at this time In the electrode deposition area, close the intake valve, open the vacuum pumping system, and start vacuuming;

[0043] (3) When the degree of vacuum in step (2) reaches 10 -4 After Pa, start preparing to make ITO transparent conductive film; turn on the electron beam power supply to preheat, increase the electron beam current at a speed of 1mA / min, and when the film formation rate is stable at 2nm / min, open the baffle to start deposition; the online test thickness reaches At 50nm, take out the sample after the deposition; put the sample in the stripping solution t...

Embodiment 2

[0050] (1) prepare the ITO raw material that purity is 99.999%, wherein SnO 2 The doping amount is 8wt%, In 2 o 3 The content is 92wt%;

[0051] (2) Put the ITO raw material in step (1) into the EB raw material boat, put the GaN sample carrying the P-type transparent electrode mask pattern after exposure and development on the sample holder, and the area not covered by the photoresist is transparent at this time In the electrode deposition area, close the intake valve, open the vacuum pumping system, and start vacuuming;

[0052] (3) When the degree of vacuum in step (2) reaches 10 -4 After Pa, start preparing to make ITO transparent conductive film; turn on the electron beam power supply to preheat, increase the electron beam current at a speed of 2mA / min, and when the film formation rate is stable at 4nm / min, open the baffle to start deposition; the online test thickness reaches When the thickness is 65nm, the sample is taken out after the deposition; the sample is place...

Embodiment 3

[0059] (1) prepare the ITO raw material that purity is 99.999%, wherein SnO 2 The doping amount is 10wt%, In 2 o 3 The content is 90wt%;

[0060] (2) Put the ITO raw material in step (1) into the EB raw material boat, put the GaN sample carrying the P-type transparent electrode mask pattern after exposure and development on the sample holder, and the area not covered by the photoresist is transparent at this time In the electrode deposition area, close the intake valve, open the vacuum pumping system, and start vacuuming;

[0061] (3) When the degree of vacuum in step (2) reaches 10 -4 After Pa, start preparing to make ITO transparent conductive film; turn on the electron beam power supply to preheat, increase the electron beam current at a speed of 3mA / min, and when the film formation rate is stable at 6nm / min, open the baffle to start deposition; the online test thickness reaches At 80nm, the sample is taken out after the deposition; the sample is placed in the stripping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com