Environment-resistant tachogenerator for aero-engine

A technology for tachogenerators and aeroengines, applied in electromechanical devices, electrical components, measuring devices, etc., can solve the problems of harsh working environment, strength, temperature resistance, corrosion resistance and sealing failure, and reach the application temperature The effect of wide range, good sealing and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

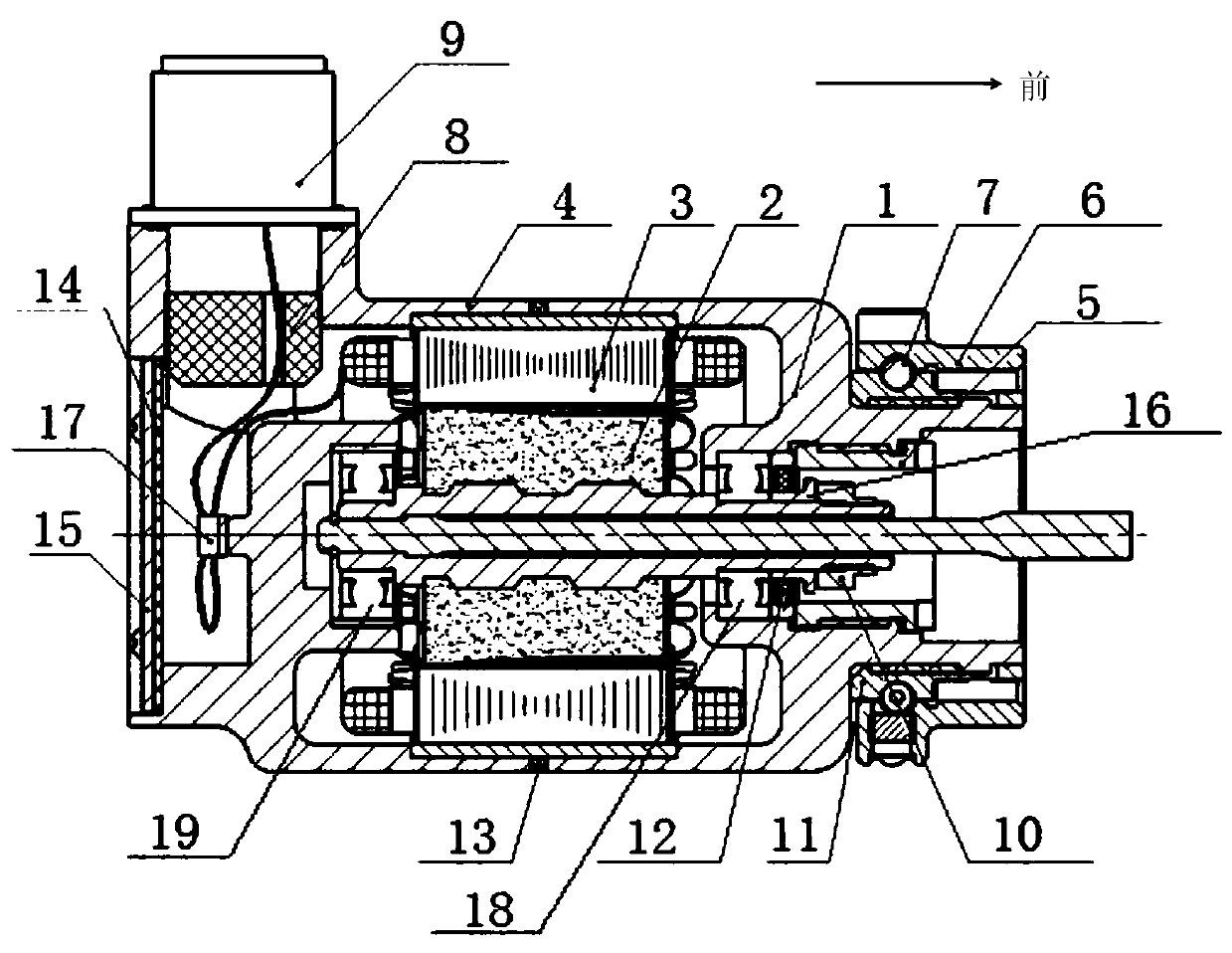

[0029] refer to figure 1 and Figure 8 , a tachogenerator for an environment-resistant aeroengine, the tachogenerator includes a front housing 1, a rotor 2, a stator 3, a rear housing 4, a lock nut 5, a connecting nut 6, a ball 7, a sealing plug 8, Connector 9, shaft end nut 10, end sleeve 11, sealing assembly 12, gasket 14, back cover 15, cover 16;

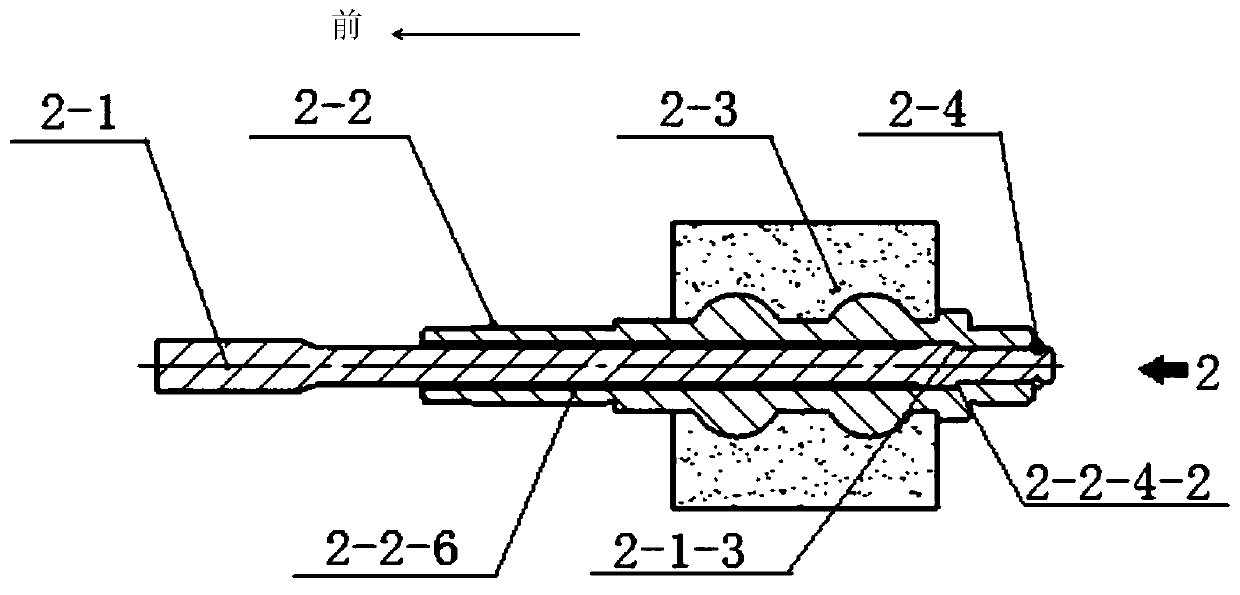

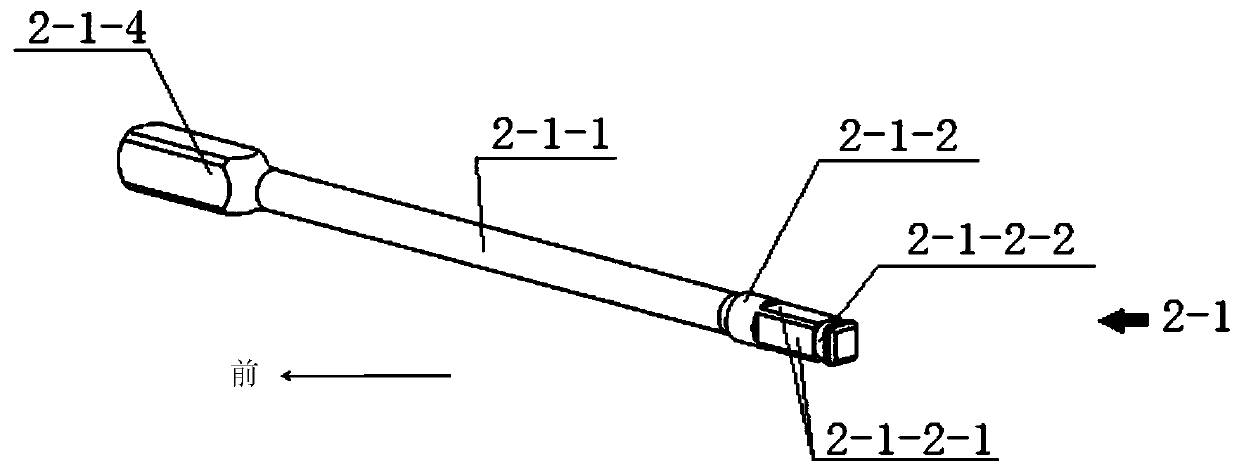

[0030] The front housing 1 and the rear housing 4 are fixed by screws, the stator 3 is placed in the cavity formed after the front housing 1 and the rear housing 4 are installed; the rotor 2 is axially placed in the stator 3, and the rotor 2 includes connecting shaft rod 2-1, shaft 2-2, magnetic steel 2-3, and stop ring 2-4. 1 Axially placed inside the shaft 2-2, an annular groove 2-1-2-2 is provided at the end of the connecting shaft 2-1, and a stop ring is installed in the annular groove 2-1-2-2 2-4;

[0031] The front and rear ends of the shaft 2-2 are supported by the first bearing 18 and the second bearing 19 placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com