A rotor winding device for motor processing

A winding device and rotor technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of inconvenient fixed installation and disassembly of the winding mechanism, achieve convenient installation and disassembly work, and increase the overall connection support strength , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

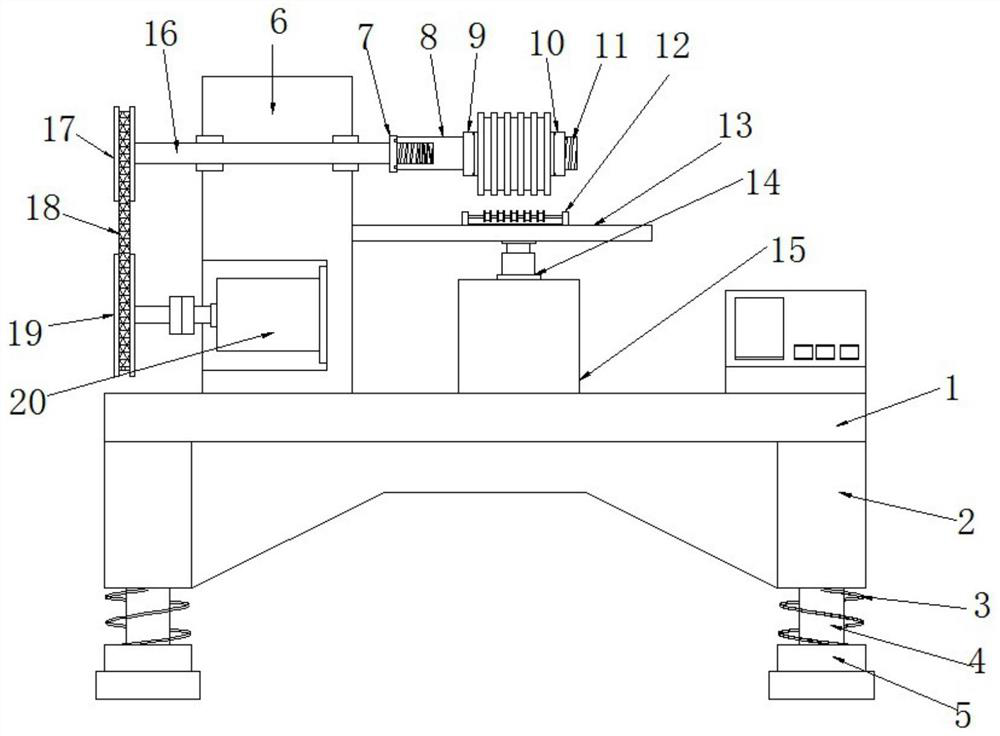

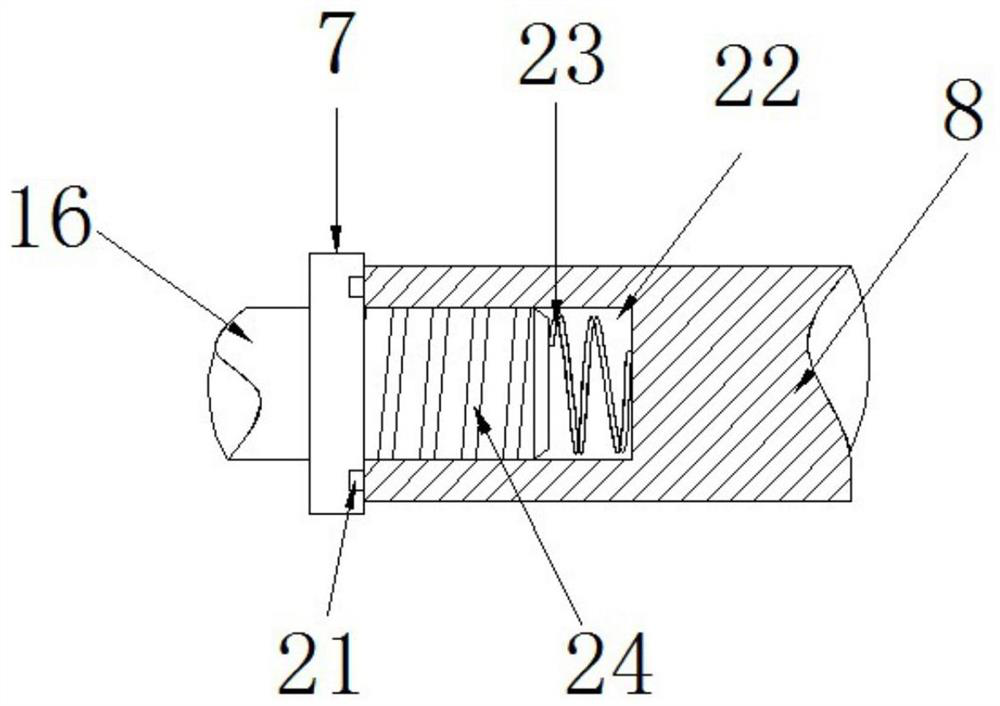

[0025] refer to figure 1 and figure 2 , a rotor winding device for motor processing, including a base 1, a boss 6 is fixed on the left side of the top outer wall of the base 1, a rotating shaft 16 is rotatably inserted on the boss 6, and one end of the rotating shaft 16 is connected with a drive Mechanism, the other end of the rotating shaft 16 is fixed with a screw rod 24, the joint between the screw rod 24 and the rotating shaft 16 is fixed with a limit ring 7, the screw rod 24 is fixed with a winding rod 8, and one end of the winding rod 8 has an insertion slot 22, and the winding rod 8 is threadedly socketed on the screw rod 24 through the insertion slot 22, and a compression spring 23 is placed in the insertion slot 22. A protruding ring 21 is fixed on the outer wall of the winding rod 8 close to the limit ring 7, and the protruding ring 21 is embedded in the In the annular groove provided on the limit ring 7 , a fixed ring 9 and a clamping ring 10 are fixedly sleeved o...

Embodiment 2

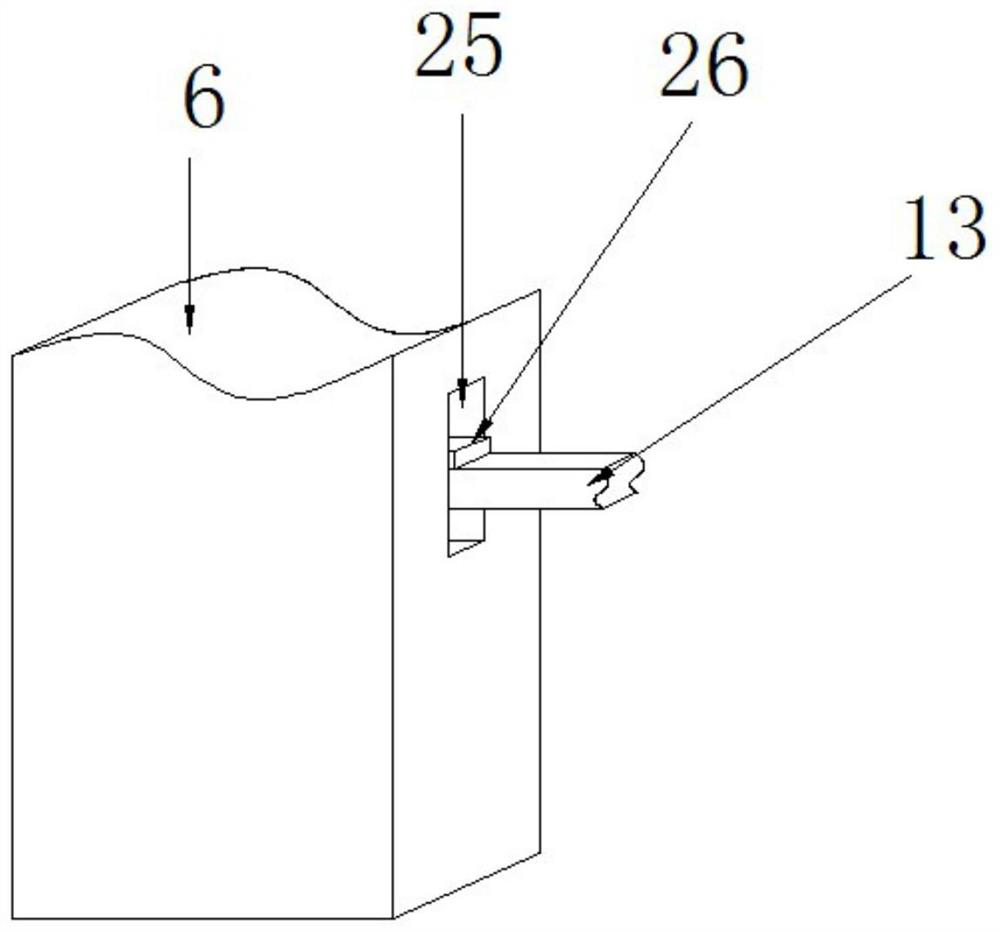

[0029] refer to image 3 , a rotor winding device for motor processing. The difference between this embodiment and Embodiment 1 is that a guide block 26 is fixed at one end of the crimping rod 13, and the outer wall of one side of the boss 6 is provided with a guide block 26 to form a sliding Cooperating guide groove 25.

[0030] The working principle of this embodiment: through the setting of the guide block 26, the guide groove 25 can cooperate with the guide groove 25 to play a position-limiting guiding role for the crimping rod 13 moving up and down, thereby increasing the stability of the distance adjustment between the crimping mechanism 12 and the winding rod 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com