Six-degree-of-freedom magnetic suspension rotary table and control system and method

A technology of magnetic levitation and degrees of freedom, applied in the field of magnetic levitation, can solve the problems of complex structure of the rotary table, less freedom of movement, and low rigidity of the platform, and achieve the effects of high power density, easy manufacture and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

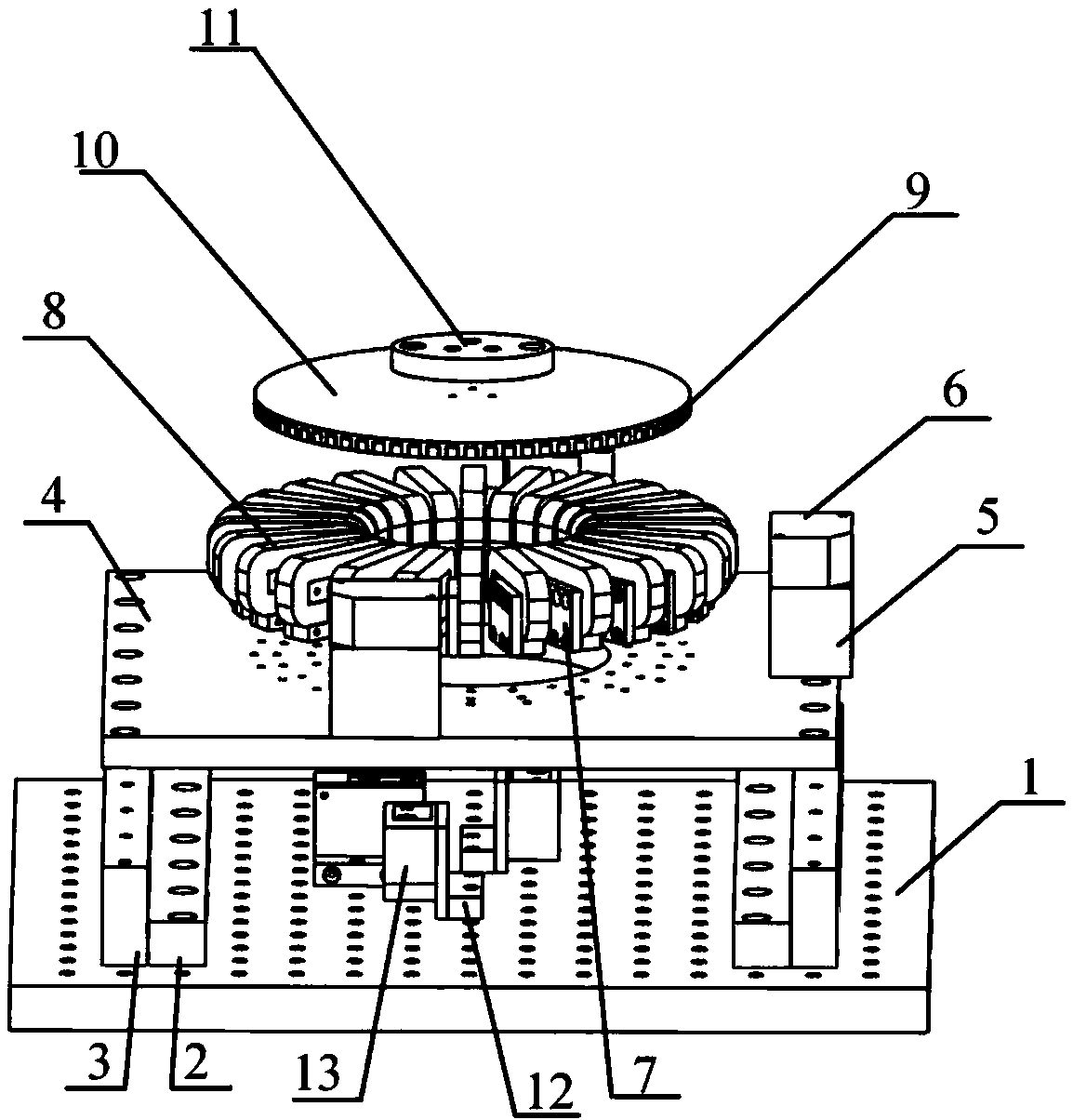

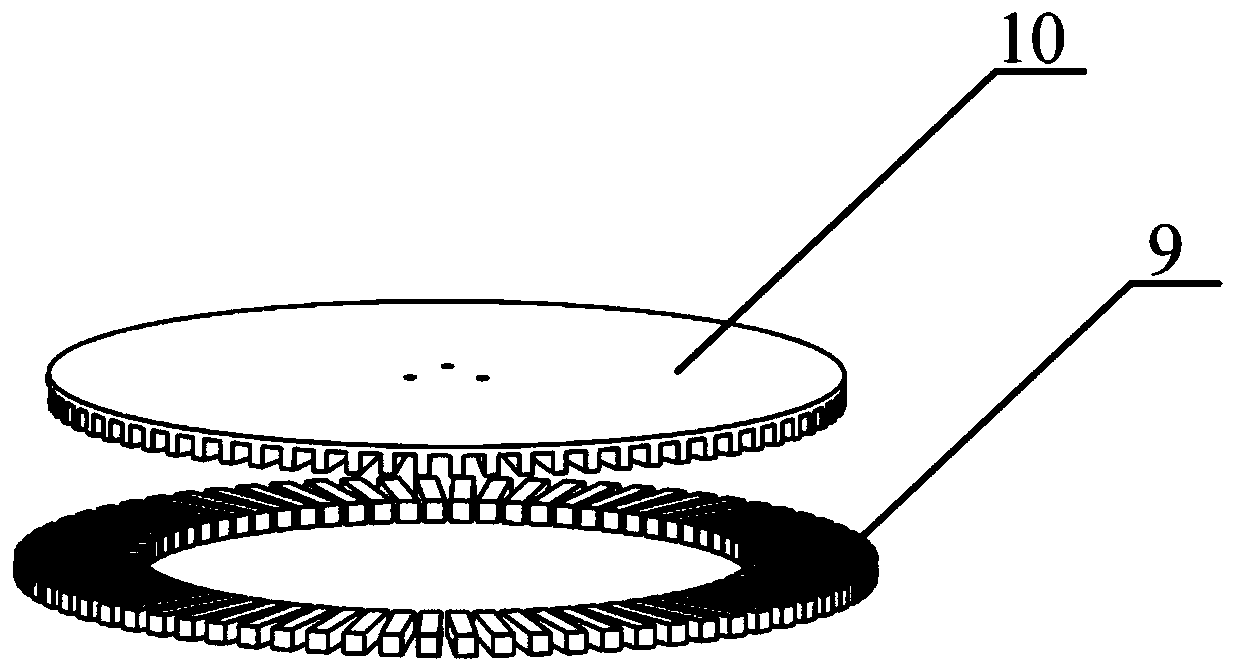

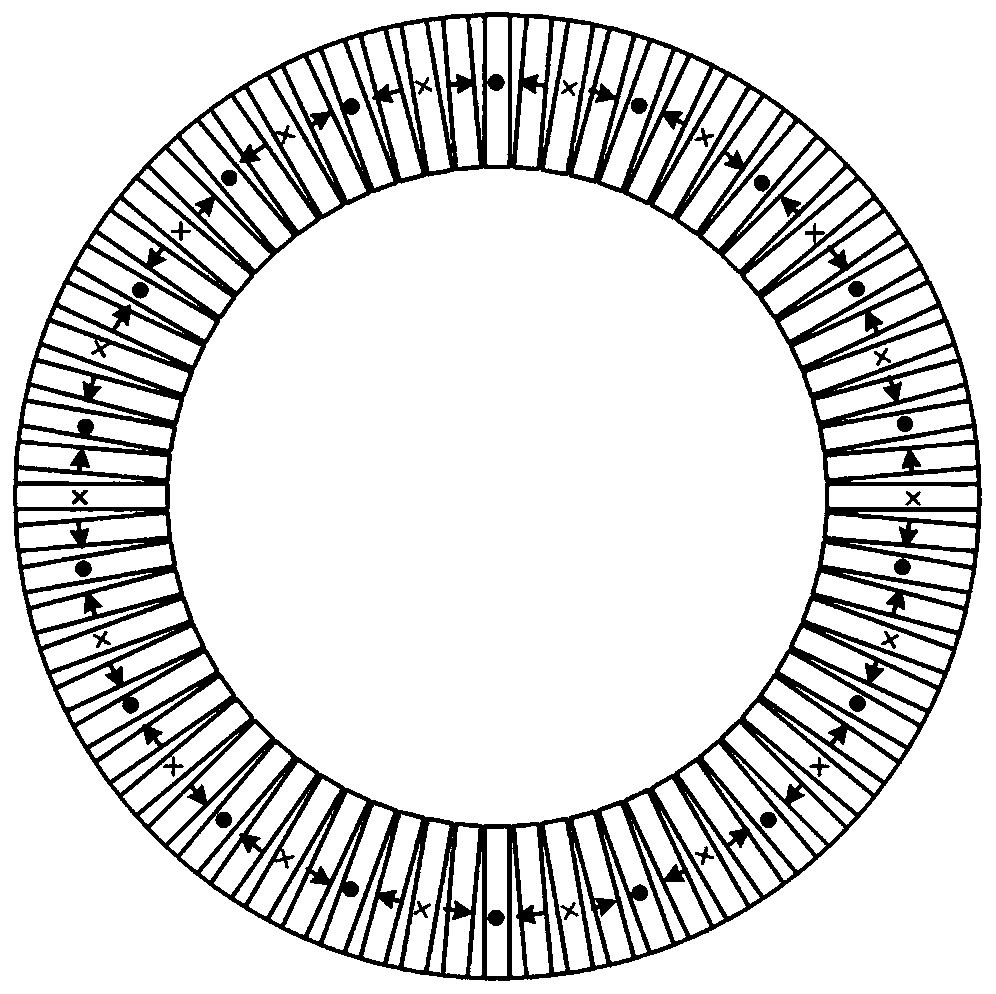

[0032] Such as figure 1 with figure 2 As shown, the six-degree-of-freedom magnetic levitation turntable of the present invention is mainly composed of an elliptical target 11, a circular stage 10, a permanent magnet array 9, a coil support 7, a coil array 8, a square base 4, an upper surface sensor support 5 and an upper The end surface photoelectric sensor 6, the lower end surface sensor bracket 12 and the lower end surface photoelectric sensor 13, the vertical support frame 3, the horizontal support frame 2, and the optical vibration isolation platform 1 are composed. Among them, the elliptical target 11, the circular stage 10, and the permanent magnet array 9 arranged in a circular shape are the mover part of the system, and the coil support 7, the coil array 8, the square base 4, the vertical support frame 3, The horizontal support frame 2 and the optical vibration isolation platform 1 constitute the stator part of the system. The system maintains a stable non-mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com