Central-wire-free stranded welding wire

A welding wire and welding core technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of easy deformation, affecting normal use, fast speed, etc., to improve corrosion resistance and combustion efficiency , enhance the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples.

[0032] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

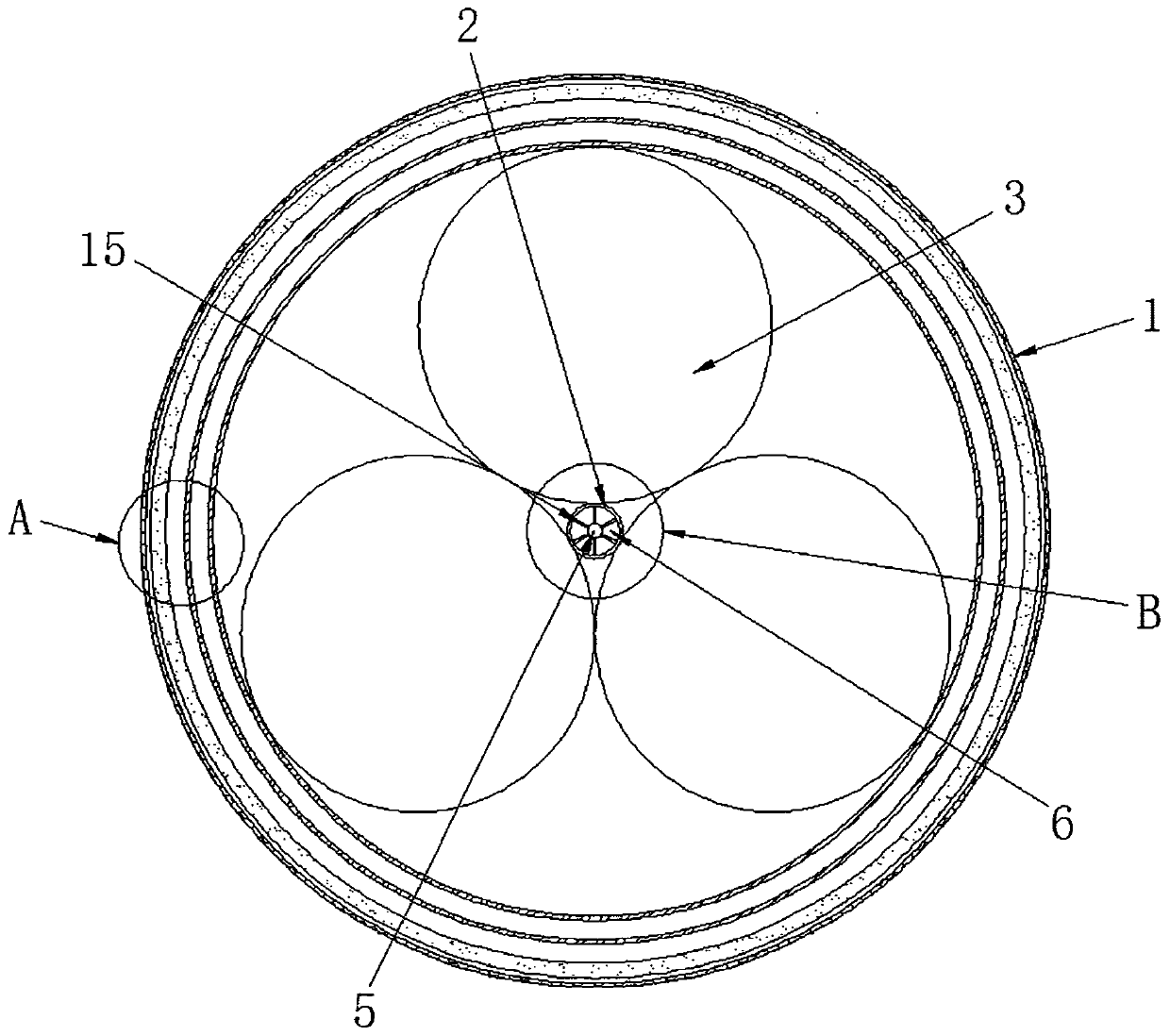

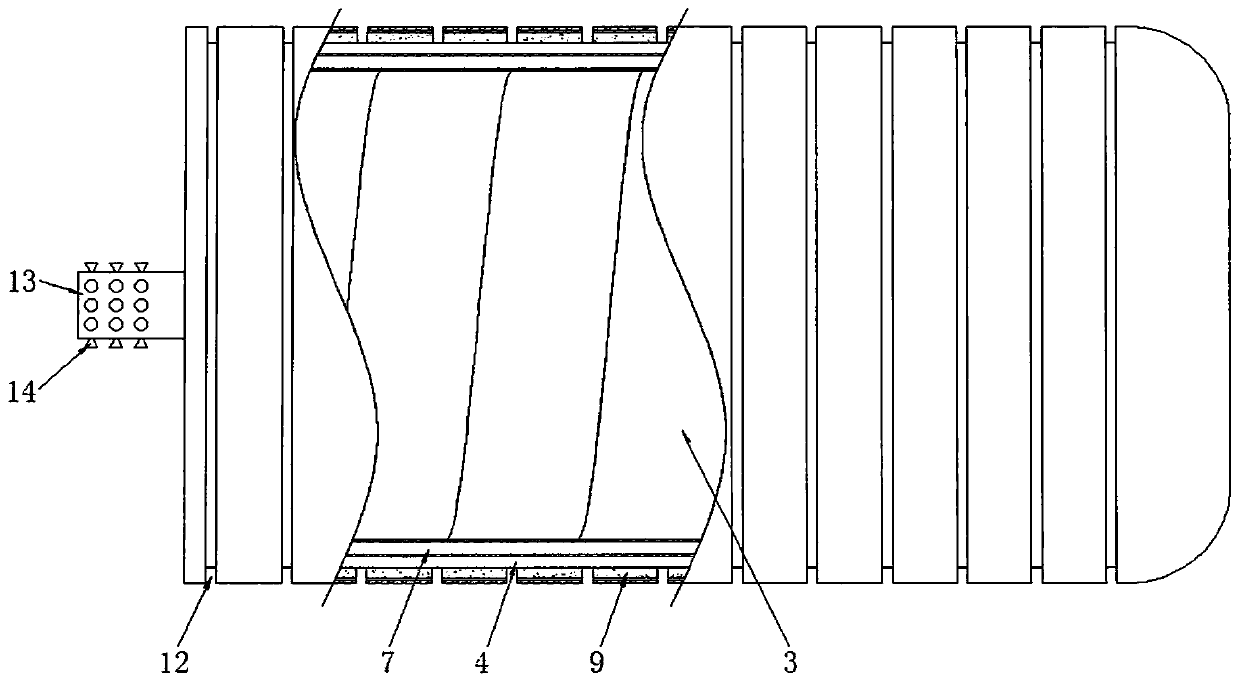

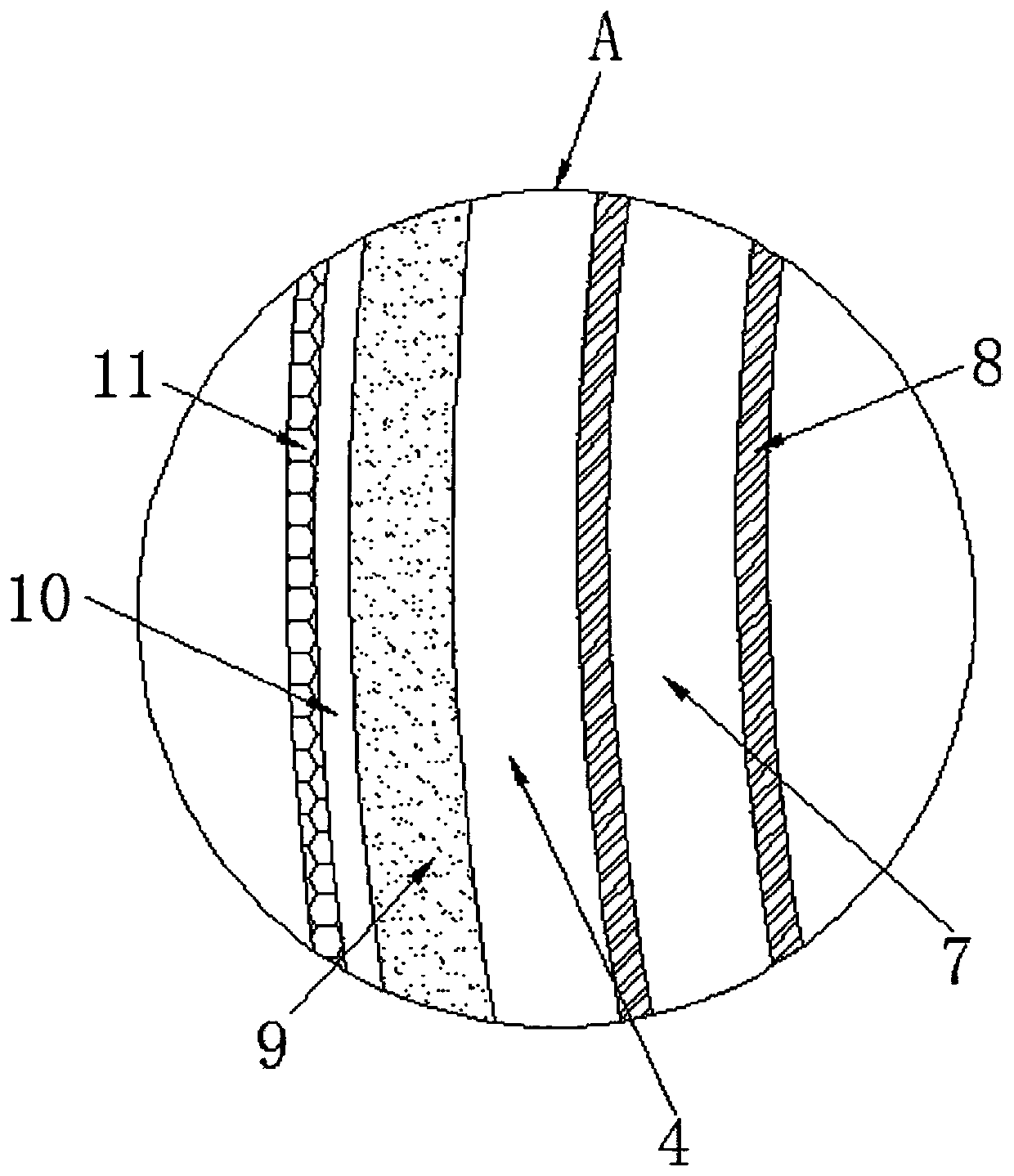

[0033] see Figure 1-4 , the present invention provides a stranded welding wire without a center wire, comprising a welding wire main body 1, the welding wire main body 1 is mainly composed of an inner sheath 2, a welding core 3, an outer sheath 7 and an outer sheath 4, the inner sheath 2, the outer sheath 7 And the material of reinforcing plate 15 is magnesium-aluminum alloy (see figure 1 , figure 2 with image 3 ); by setting the magnesium-aluminum allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com