Full-automatic control monitor and monitoring method for extrusion amount of 3D printer nozzle

A technology of 3D printers and extrusion volume, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc. It can solve problems such as waste of raw materials, poor printing effects, and collapse, and achieve a wide range of applications. The effect of practical value and practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

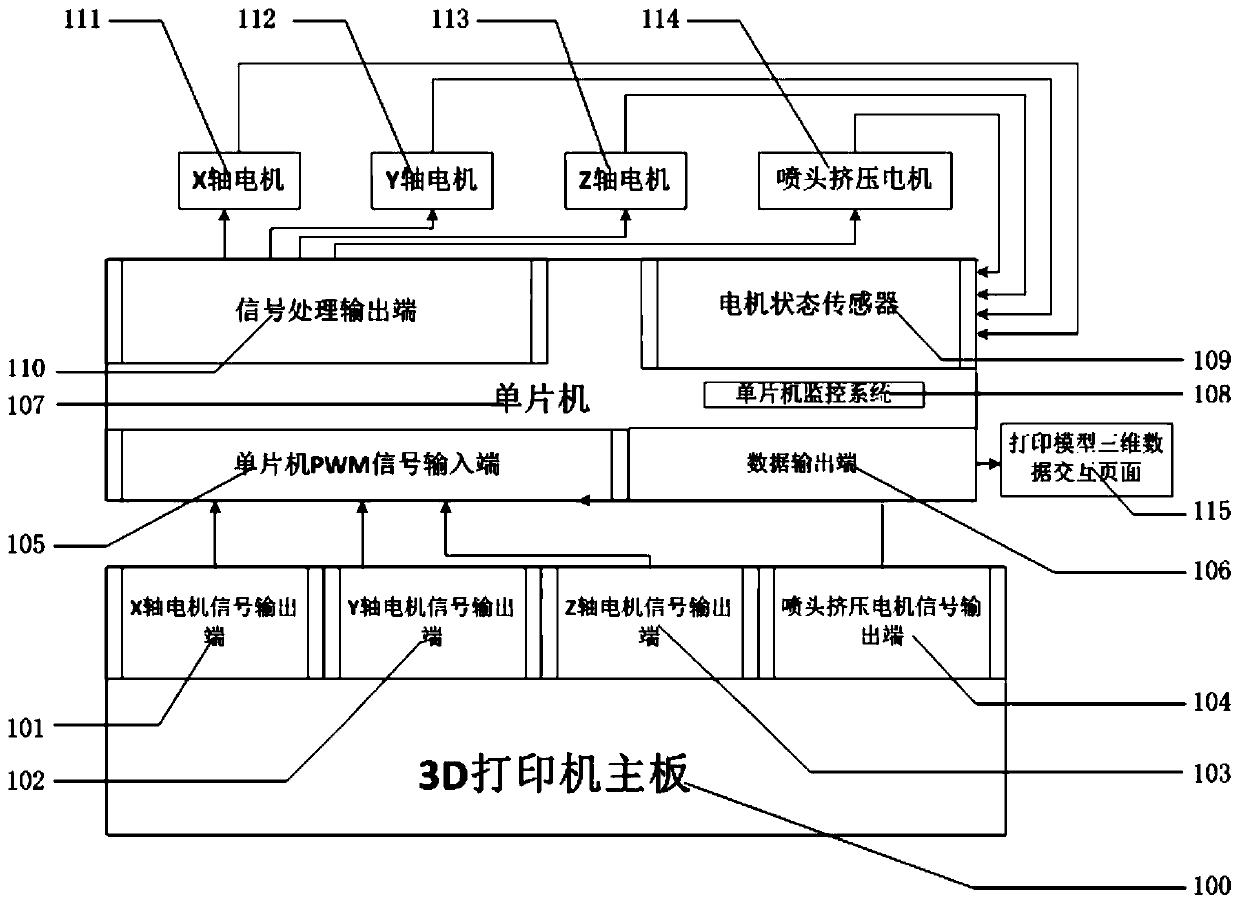

[0029] For the circuit part, please refer to the attached figure 1 , a 3D printer nozzle extrusion volume automatic control monitor, located between the 3D printer main board 100 and the motor, the motor includes an X-axis motor 111, a Y-axis motor 112, a Z-axis motor 113 and a nozzle extrusion motor 114 , which includes a single-chip microcomputer 107, and a PWM signal input terminal 105, a signal processing output terminal 110, a data output terminal 106, and a plurality of motor state sensors 109 respectively connected to the single-chip microcomputer 107, and the PWM signal input terminal 105 is connected to the 3D printer main board 100 pair The drive signal output terminals of each motor, the signal processing output terminal 110 is connected to each motor to output a drive signal, the data output terminal 106 is used to output the printing model data pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com