Special-shaped polyamide 6 filament and preparation method thereof

A nylon and special-shaped technology, which is applied in the field of special-shaped nylon 6 filaments and its preparation, can solve the problems of moisture absorption and perspiration, poor bulkiness, poor luster of nylon 6 filaments, and insufficient color, and achieve a large reflective effect and enhance capillary effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

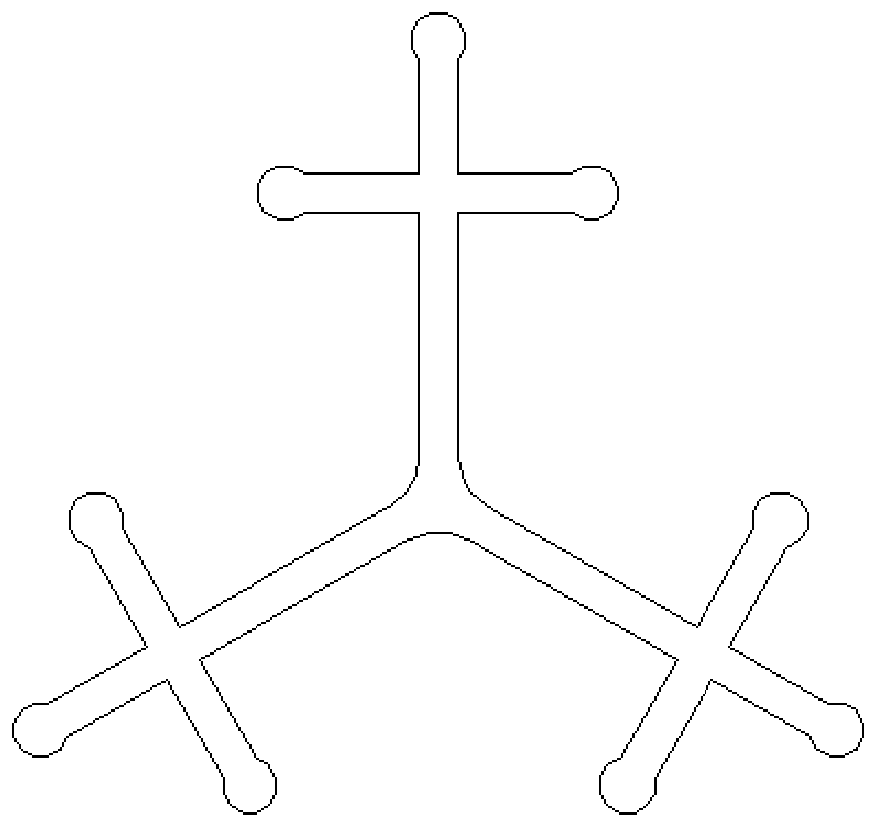

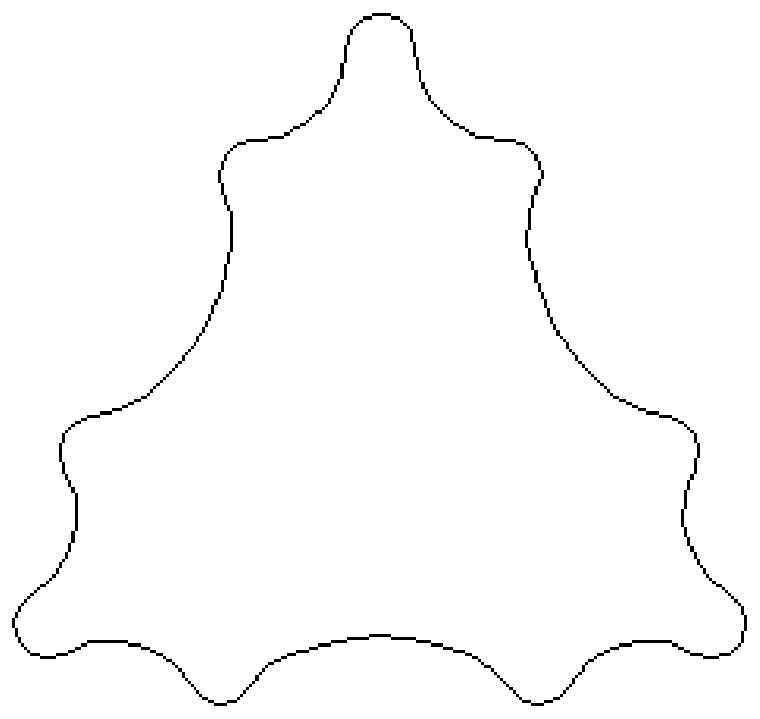

[0019] Please refer to Figure 1 to Figure 2 Shown, the preparation method of a kind of special-shaped nylon 6 filament of the present invention, comprises the following steps:

[0020] Step 1, mixing and melting nylon 6 dry slices with a relative viscosity of 2.30-2.50 and color masterbatch to obtain a nylon 6 melt;

[0021] Step 2, extruding the nylon 6 melt obtained in step 1 through the spinneret micro-holes on the spinneret to obtain nylon 6 filament tow;

[0022] Step 3. The nylon 6 filament tow obtained in step 2 is sequentially subjected to monomer suction, side blowing cooling, cluster oiling, stretching and setting, and network interlacing, and then winding and forming to obtain special-shaped nylon 6 filament;

[0023] The spinneret includes a substrate and at least one spinneret microhole, the spinneret microhole is arranged on the substrate, the cross section of the spinneret microhole is trilobal, and the two adjacent blades The included angle is 120°, and the ...

Embodiment 1

[0039] A preparation method of special-shaped nylon 6 filaments, specifically comprising the following steps:

[0040] Step 1, mixing and melting nylon 6 dry slices with a relative viscosity of 2.30-2.50 and black masterbatch to obtain a nylon 6 black melt;

[0041] Step 2, extruding the nylon 6 melt obtained in step 1 through the spinneret micro-holes on the spinneret to obtain nylon 6 black filament tow;

[0042] Step 3. The nylon 6 filament tow obtained in step 2 is sequentially subjected to monomer suction, side blowing cooling, cluster oiling, stretching and setting, and network interlacing, and then winding and forming to obtain special-shaped black nylon 6 filament;

[0043] The spinneret includes a substrate and at least one spinneret microhole, the spinneret microhole is arranged on the substrate, the cross section of the spinneret microhole is trilobal, and the two adjacent blades The included angle is 120°, and the shape and size of each blade are the same; the bla...

Embodiment 2

[0047] A preparation method of special-shaped nylon 6 filaments, specifically comprising the following steps:

[0048] Step 1, mixing, melting, kneading, compressing and extruding nylon 6 dry slices with a relative viscosity of 2.30-2.50 and fluorescent white masterbatch to obtain a nylon 6 fluorescent white melt;

[0049] Step 2, extruding the nylon 6 melt obtained in step 1 through the spinneret micro-holes on the spinneret to obtain nylon 6 fluorescent white filament tow;

[0050] Step 3. The nylon 6 filament tow obtained in step 2 is sequentially subjected to monomer suction, side blowing cooling, cluster oiling, stretching and shaping, and network interlacing, and then winding to obtain special-shaped fluorescent white nylon 6 filament;

[0051] The spinneret includes a substrate and at least one spinneret microhole, the spinneret microhole is arranged on the substrate, the cross section of the spinneret microhole is trilobal, and the two adjacent blades The included ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com