Adjustable support of magnetic levitation track

A technology of magnetic levitation track and support, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of inability to meet the precision adjustment requirements in the operation stage, high installation precision control requirements, and difficult design and processing, so as to achieve good application prospects and ensure operating speed and riding comfort, reducing the difficulty of laying and the effect of maintenance intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

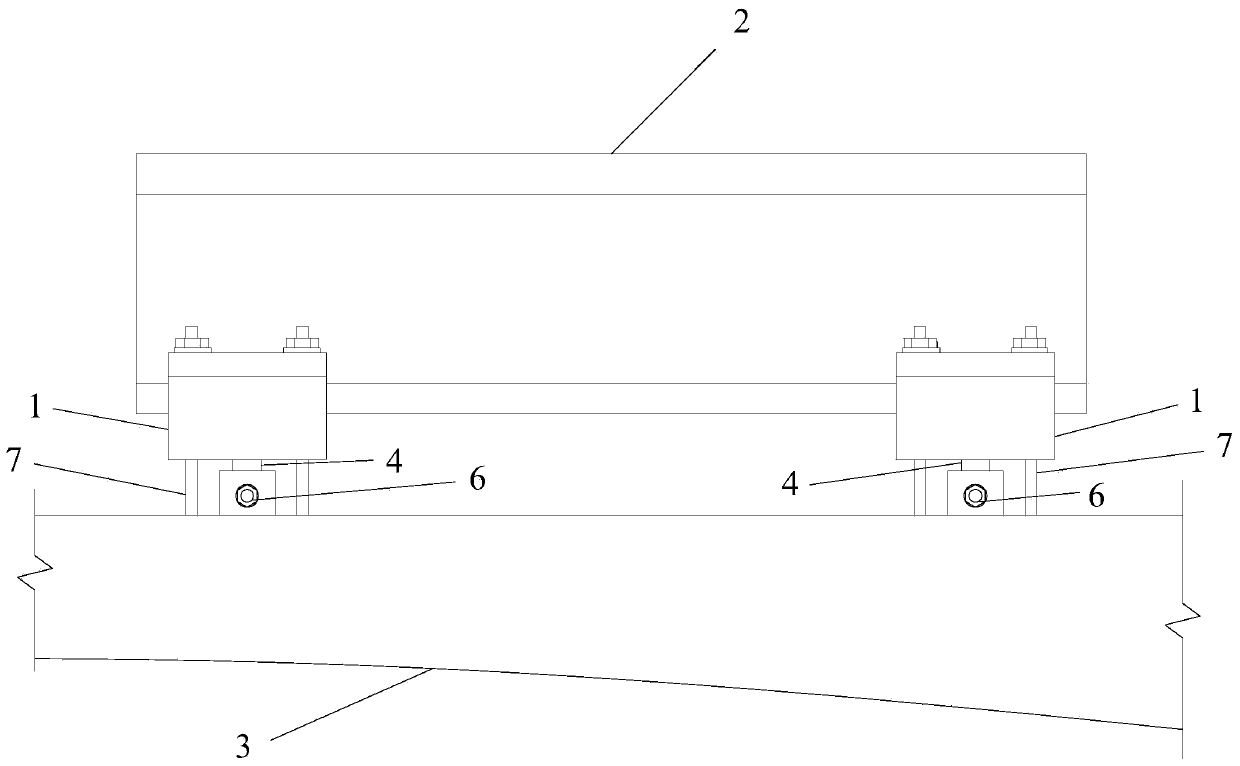

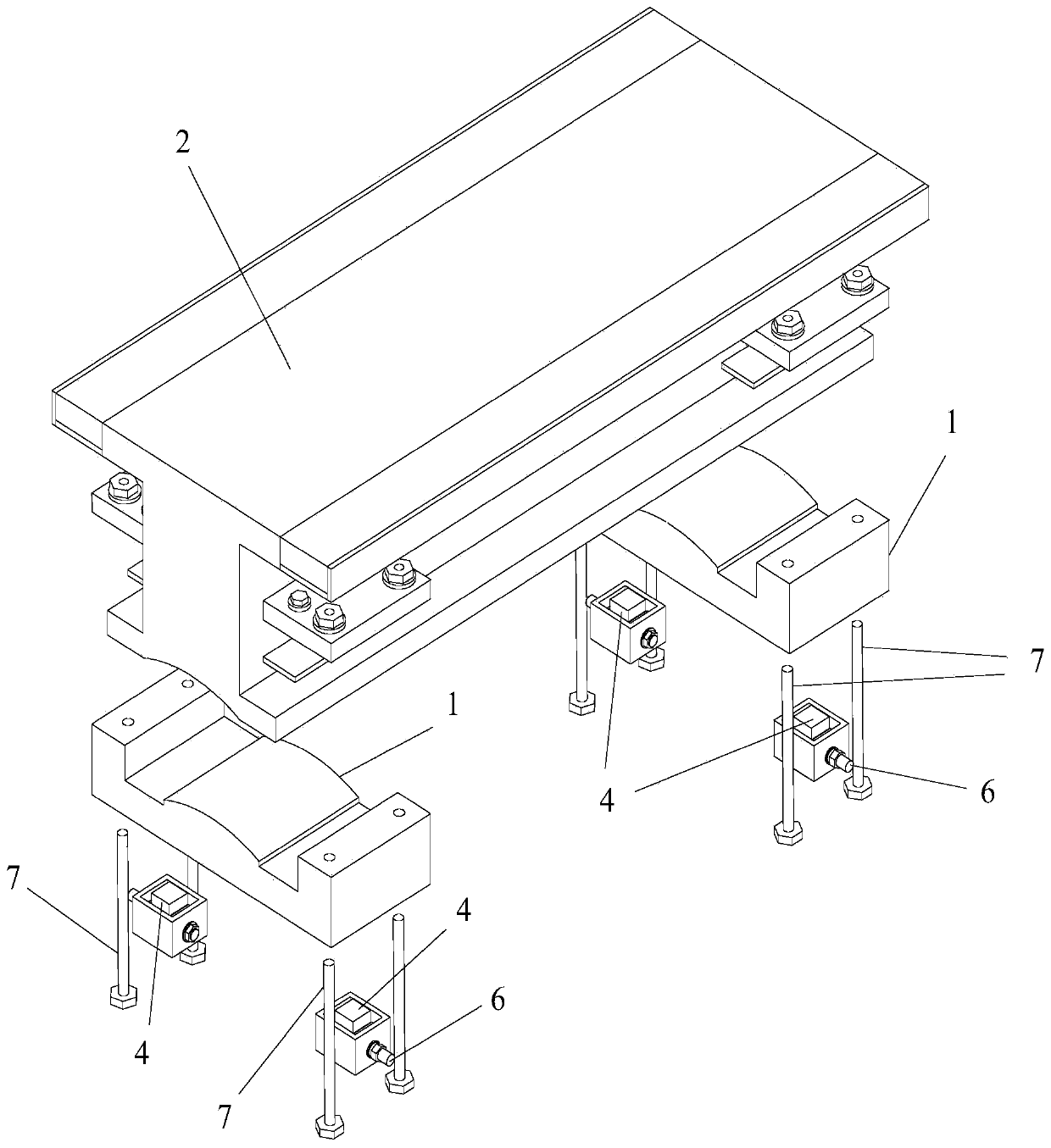

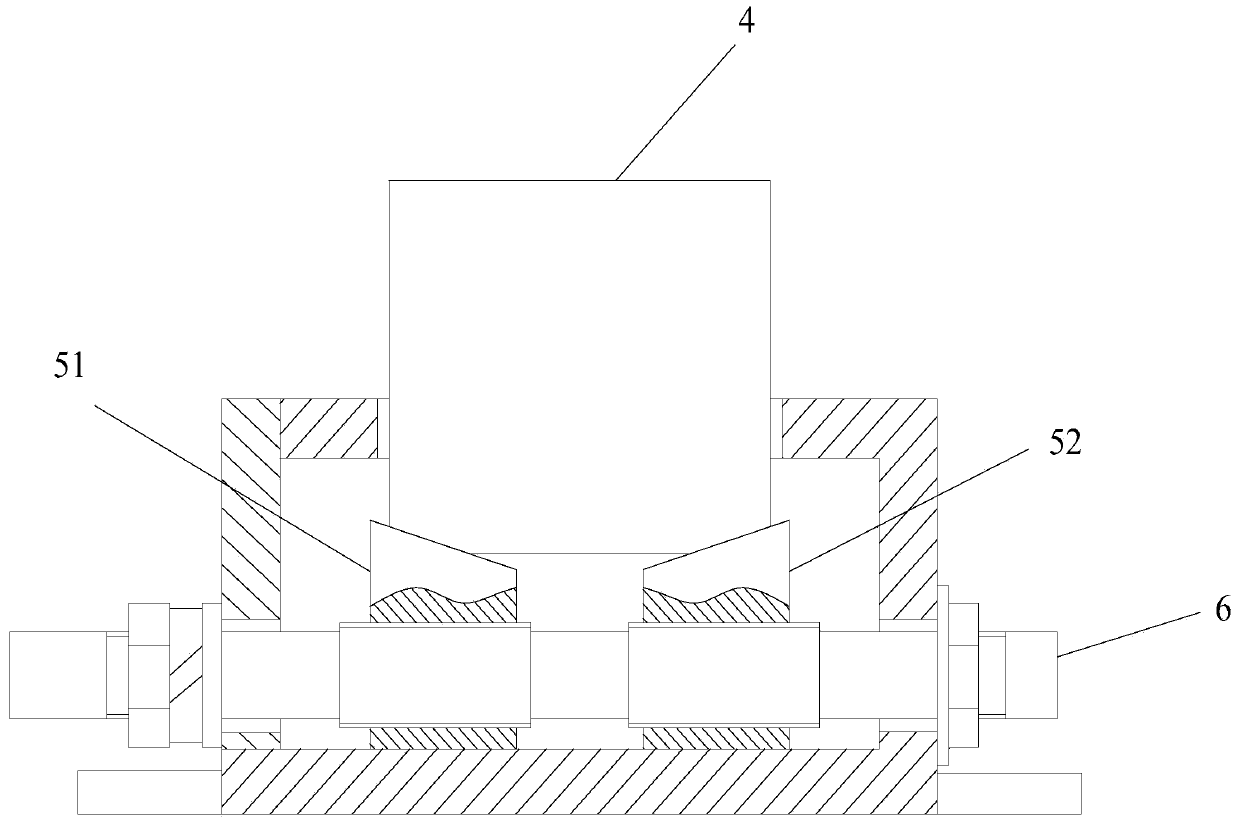

[0030] Such as Figure 1-4 As shown, the adjustable support of a magnetic levitation track according to the present invention includes a support plate 1 and two jacking parts, and the support plate 1 is used to connect between the track beam 2 and the load-bearing beam 3, The two jacking parts are respectively arranged on opposite sides of the support plate 1, each of the jacking parts is used to raise or lower the corresponding side of the support plate 1, so that the track Both sides in the width direction of the beam 2 are raised or lowered respectively.

[0031] The load-bearing beam 3 can adopt a reinforced concrete structure, which effectively reduces cost and processing accuracy compared with steel beams. The support plate 1 is connected to the track beam 2 and the load-bearing beam 3 respectively. In this embodiment, for example Figure 1-2As shown, the support plate 1 is arranged along the width direction of the track beam 2, the support plate 1 is a groove structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com