Water-vapor mixing system of super pressing and suction combined pumping system and working method thereof

A water-vapor mixing and super technology, applied in the direction of pressure pumps, infrastructure engineering, machines/engines, etc., can solve problems such as increased equipment costs, high labor costs, and water column height restrictions, and achieve the effects of saving equipment costs and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

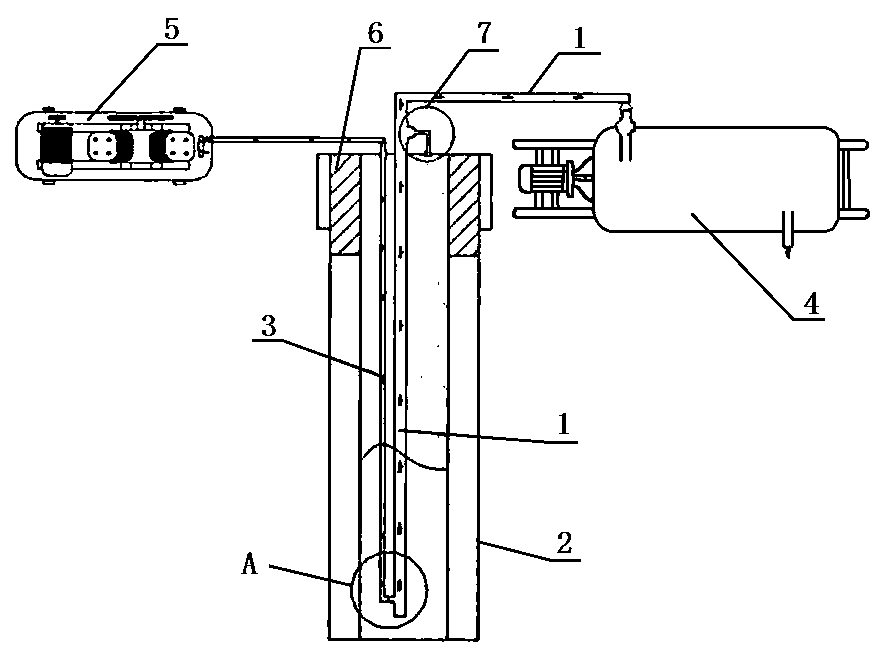

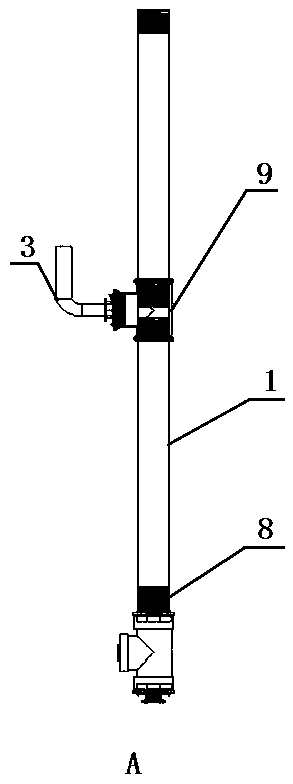

[0018] Example: such as figure 1 , 2 As shown, the present embodiment specifically relates to a water-steam mixing system of a super pressure-suction combined pumping system and its working method. The water-steam mixing system includes a pumping device and an air supply device arranged on the dewatering well 2, wherein:

[0019] The pumping device mainly includes a water outlet pipe 1, a vacuum pump 4, and a vacuum application device 7. The vacuum pump 4 is arranged at the entrance ground of the dewatering well 2. One end of the water outlet pipe 1 is connected with the vacuum pump 4, and the other end runs through the sealed well cover at the wellhead of the dewatering well 2. 6 and extend vertically to the bottom of the dewatering well 2. In addition, the vacuum applying device 7 is specifically a pipe body. One end of the vacuum applying device 7 runs through the sealed manhole cover 6 and communicates with the upper part of the dewatering well 2, and the other end communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com